Scientists from Nanyang Technological University in Singapore and Université Grenoble Alpes in France have combined a slot-die coating technique with gas quenching and substrate heating to fabricate a perovskite solar cell with an active area of over 0.09 cm2 and a power conversion efficiency of 18%.

Gas quenching is used primarily in connection with hardening in vacuum furnaces and slot-die coating is a process already used in various industries. Ink is pushed through a narrow slot as it moves across a substrate to form a continuous film. Substrate heating is commonly applied in the pulsed laser deposition (PLD) process.

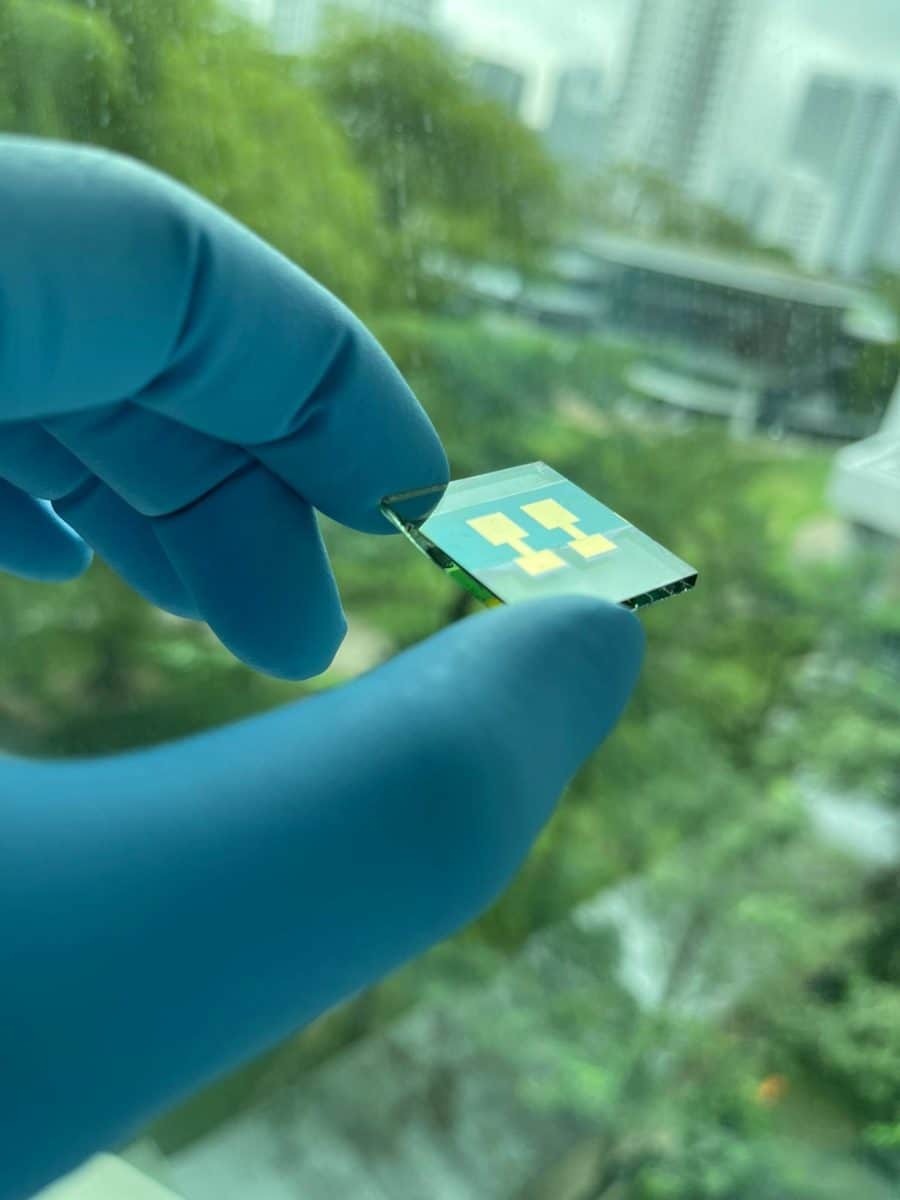

These techniques, which the researchers described as a combined “synergistic crystallization strategy,” was used to coat a methylammonium-free perovskite film with a thickness of around 500 nm over a fluorine-doped tin oxide (FTO) substrate of 10 × 10 cm2 without the use of solvents or additives.

The perovskite precursor ink was prepared in a nitrogen-filled glovebox by mixing lead(II) iodide (PbI2), formamidinium iodide (FAI), lead(II) bromide (PbBr2), and cesium iodide (CsI).

“The solution was kept at 40 C under stirring overnight and transferred to the slot-die tubing system the next day,” the scientists said. “For the perovskite module fabrication, P2 scribing was performed with a CO2 laser with adjusted power to remove specifically the perovskite and the hole transport layers and a manual P3 step was performed by Kapton tape masking.”

The cell has an ‘n-i-p' layout and is composed of the fluorine-doped tin oxide (FTO) substrate, a Tin(IV) oxide (SnO2) layer, the perovskite film, a layer made of gold (Au). It also has a spiro-OMeTAD hole-blocking layer, which is typically used as a hole transport material for solid-state dye solar cells and perovskite devices.

Popular content

The best performing slot-die coated solar cell showed an efficiency of 18.03%, an open-circuit voltage of 1024 mV, a fill factor of 78.6% and short-circuit current density of 22.4 mA cm−2.

“The device performance reproducibility was assessed by fabricating 30 devices from the same substrate,” the academics said, adding that their average efficiency was 16.35%.

They described the cell and the related production process in “Slot-die coated methylammonium-free perovskite solar cells with 18% efficiency,” which was recently published in Solar Energy Materials and Solar Cells.

“This work provides an insight into the processing window for perovskite meniscus coating and paves the way toward large-scale processing of MA-free perovskites,” the researchers said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

9 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.