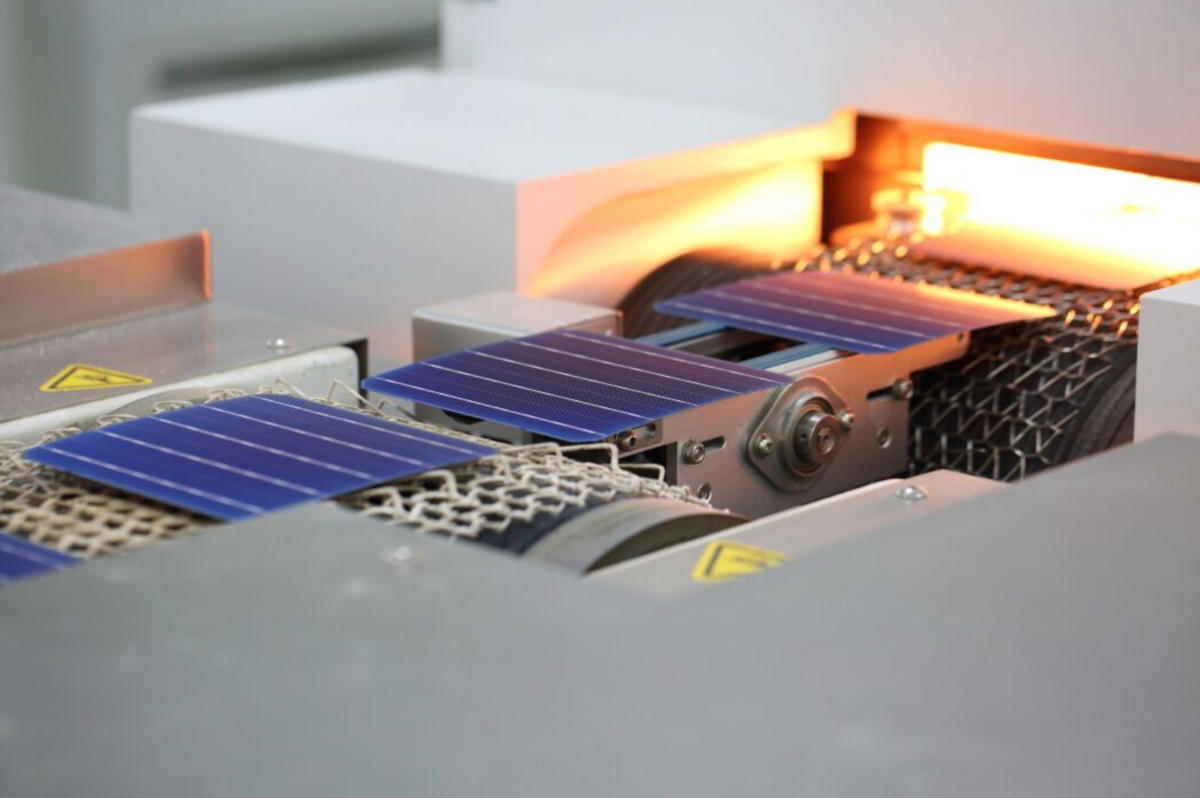

The deployment of solar PV is gaining momentum as the cheapest clean replacement of fossil fuel electricity generation. But the manufacturing of silicon solar cells is at such a scale that to change production of the dominant technology, PERC, or to reconsider investment in emerging technologies such as heterojunction solar cells, is like turning an ocean liner.

A new research paper – a data-driven, number-crunching exposé from scientists at the University of New South Wales School of Photovoltaic Renewable Energy and Engineering (SPREE) – shows that to meet projected solar generation requirements of some 70 terawatts of solar PV by 2050, the industry must urgently steer toward technologies that use less silver, bismuth and indium.

Adjunct Professor Pierre Verlinden has been sounding the alarm of material scarcity in PV for years. Associate Professor Brett Hallam, a SPREE researcher working on how to increase the efficiency of solar cells, is worried about the sustainability of upcoming solutions to boost efficiency. And Yuchao Zhang began his PhD research around the metallization and screen printing used in solar cells when Verlinden and Hallam suggested he look at sustainability first.

“We did some quick calculations that showed, OK, there is definitely a problem for the future consumption of silver, bismuth and indium,” Zhang tells pv magazine Australia.

A team of five co-authors was formed to look into global reserves of these resources, and they drew on the combined expertise of SPREE to calculate how much of each material is currently being used in dominant and emerging technologies, and how much will be required for future PV production.

Popular content

“Then, from a more technical perspective, we looked at the impact on cell performance of reducing the use of these substances, and how far we could reduce the usage in different solar cell technologies,” says Zhang.

The upshot of the paper – “Design Considerations for Multi-terawatt Scale Manufacturing of Existing and Future Photovoltaic Technologies: Challenges and Opportunities Related to Silver, Indium and Bismuth Consumption,” which was recently published in Energy & Environmental Science – is that the industry and academics must temporarily put aside the pursuit of greater solar cell efficiency and instead focus their abilities on primarily reducing the use of silver in PV.

Possible efficiency gains from new technologies cannot yet neutralize the draining of silver, bismuth and indium reserves as manufacturers ramp up PV capacity to respond to demand for clean energy at a scale that will significantly impact climate change.

The paper takes as its basis that PV module production must increase from 135 GW in 2020 to 3 TW by 2030. It assumes an upper material consumption limit of 20% of 2019 global supply of the three most constrained materials, given that other industries also have a claim to those reserves.

To continue reading, please visit our pv magazine Australia website.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.