Can you tell me about the Zinc Battery Initiative and why it was established?

The initiative is a consortium of battery companies and stakeholders that use zinc-based battery technology, as we realized it's very important to have a common voice to represent this industry sector.

We have a very wide spectrum of members with different approaches and we believe it's better to have a platform with different choices, almost like a menu, so you can best choose what suits your needs. And from what we hear, everybody wants safety and now, with supply chain issues and EVs being so successful, it’s not practical to rely solely on lithium.

What advantages do zinc batteries offer over other chemistries?

Zinc is very versatile and you can apply it to all kinds of applications and configurations, starting from very small formats. We just had a new member joining, Imprint Energy, which makes printed zinc batteries and they have found their niche in tracking sensors and the internet of things. Before zinc, they tried to use lithium-based technologies in a coin cell or other small formats but with lithium, there is so much packaging required to ensure safety. So, in the same volume, zinc-based technologies are almost 10 times better than lithium. Of course, in terms of energy density, lithium takes the win.

Zinc is very versatile and you can apply it to all kinds of applications and configurations, starting from very small formats. We just had a new member joining, Imprint Energy, which makes printed zinc batteries and they have found their niche in tracking sensors and the internet of things. Before zinc, they tried to use lithium-based technologies in a coin cell or other small formats but with lithium, there is so much packaging required to ensure safety. So, in the same volume, zinc-based technologies are almost 10 times better than lithium. Of course, in terms of energy density, lithium takes the win.

On the other end of the spectrum, if we look at large scale applications, there are zinc-flow batteries. One of our members, Australia-based Redflow, has just finished the installation of a 2MWh zinc-bromine system in California. We also have zinc-air flow batteries, such as the ones supplied by Canada’s Zinc8, where the size of your electrolyte tank determines the hours of storage. So you can go to 10 or 50 hours, even 100 hours of storage, but after that it makes sense to consider hydrogen.

These are the extreme ends, but there also is a lot in between. For instance, in data centers and server farms you need short-duration, reliable, instantaneous power, and this is where nickel-zinc excels. Two of our members, U.S.-based ZincFive and AEsir, are supplying this technology, and the latter one has recently secured financing for a gigawatt manufacturing facility in South Dakota. AEsir has … 30-year experience in zinc-based systems and is working on new cathodes they call rechargeable hybrid cathodes. They use lower cost components and circumvent nickel, the price of which has been rising.

What other configurations are there to see in the market?

There also are zinc batteries that are using low-cost, manganese-based cathodes. One of our other members, New York-based Urban Electric Power, is producing manganese-zinc batteries with an alkaline electrolyte and its focus is on residential storage. Also, we have two more members both looking at residential applications, Sweden-based Enerpoly and Canada-based Salient Energy, pursuing another way of doing manganese-zinc batteries. That is the newest approach in this chemistry, where manganese-dioxide is tweaked in a way that it works like a lithium-ion battery in mechanical terms and has zinc ions moving back and forth but with twice the charge than that of lithium. This tech can share production infrastructure with lithium-ion but it’s a water-based system, so there is no need for a dry room that lithium-ion batteries need as they don’t tolerate moisture.

Also, there are zinc-air batteries. Unlike flow batteries that require pumps and more moving parts, Canada-based e-Zinc has a system which uses a container that can be sized from two to 50 hours of storage. Their system is gravity based, with zinc generated in the upper section of the unit cell and moving to the lower section where it is used. We also have U.S.-based Enzinc among our members. They have commercialized a zinc sponge electrode and aim to get into the mobility market, to be used in e-bikes, golf carts or small-distance cars. In general, I think there's great opportunity for zinc-based technology. We know it works but it just needs to be applied and deployed at scale.

And from all these configurations that you just mentioned, which one has gone the furthest in terms of the deployment?

Those would be nickel-zinc systems for data centers and transportation hubs. On the upper end, we have the zinc-flow systems and zinc-air systems which are in demonstration phases. Many of these systems still are not in the stage when you can just go and buy a unit, but we’ll get there.

So what does the future hold for zinc-based battery storage systems?

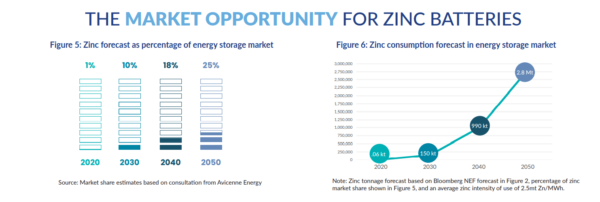

Right now, the market share of zinc-based technologies is very little but we think it will go to around 25% by 2050. So based on [the] BloombergNEF NEO 2020 [New Energy Outlook report] forecast for storage batteries, and [the] percentage of zinc market share estimates based on consultation with French company Avicenne Energy, the zinc energy storage market share is forecast to stand at 10% in 2030, 18% in 2040, [and] 25% in 2050.

Another interesting aspect in the supply chain [is that it] can be completely westernized. Zinc is globally mined and refined in 50 countries so supply is secure and conflict free.

The first nickel zinc batteries were invented by Thomas Edison but quickly fell out of favor. What has happened in the meantime that we are now seeing all these manufacturers emerging?

The fate of all batteries is determined by application. You have a need, and then you have a certain battery type to go with it. In the 90s, there was so much research going into lithium, and zinc-based batteries were considered an old technology. But now, 20 years later, things are different. We also are aware of the problems with lithium-ion batteries and researchers are thinking what other types of batteries can be made and what is needed. So they were looking at the drawbacks of the zinc-based battery systems, such as shape change and dendrite formation, and resolved these issues. It’s a very old technology but often companies decide to use their secret mixes and don’t give away all their ingredients. Of course the common goal is to control shape change so that you don’t lose energy over cycles, as well as to address forming of dendrites and thus prevent an early system failure. Those two issues were the reason behind the short life in zinc-based batteries but they have been resolved.

Can you say something about the technology’s technical aspects?

Zinc-based batteries have a wide operating temperature range [of] between -40 degrees Celsius to 75 degrees Celsius, depending on the application and recommendations of individual manufacturers. Overall, [the] life of the systems depends on the chemistry you use, for instance in flow batteries there is no degradation, so you’ll probably shoot for 20 years but of course you’ll need some maintenance. This is if you do accelerated testing, and we’ll know the real lifespan in 20 years, as the installations are just starting.

Charge cycles depend on which cathode you use and what your chemistry is. For example, zinc-ion can last as long as lithium-ion batteries. In manganese-zinc and alkaline configurations, the cycle life will mostly depend on how deep you discharge, similar to lead acid but still better performance. For zinc-flow it could be, even, up to 20,000 cycles. Depending on the zinc-based battery technology applied, the energy density can be similar to lead acid batteries and can go from 70-150Wh/kg. With zinc-air systems, which has theoretical energy densities in excess of 1,000Wh/kg, higher values may be attainable

Where do the zinc batteries fall in with all the other available chemistries on the market and what are their best applications?

Nickel-zinc batteries are a great fit for data centers and server farms where, still, mainly lead acid batteries are being used today, as well as for military applications such as submarines. Then, manganese-zinc systems will be used in applications where two to six hours of storage is needed. As we go along with demonstrations and the need for longer-duration storage grows, we will eventually have zinc-based batteries providing baseload power in combination with renewable energy sources.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

6 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.