Sodium-ion batteries offer advantages in terms of raw material costs and safety, but there is still room for improvement if they are to supersede the ubiquitous lithium-ion technology. Now, new research promises to lower manufacturing costs and improve the performance of sodium-ion batteries by virtue of micro-architected electrodes.

In a study that was recently published in the journal Small, researchers at Tohoku University in Japan examined ways to develop high-performance, low-cost sodium-ion batteries by increasing the loaded amount of active materials used to make a battery into a single battery cell. Their approach reduces the inactive components that are used for binding multiple cells together, compacting the battery size and lowering the costs of the ingredients. However, it requires the fabrication of thicker electrodes, which restricts ion movement within the battery.

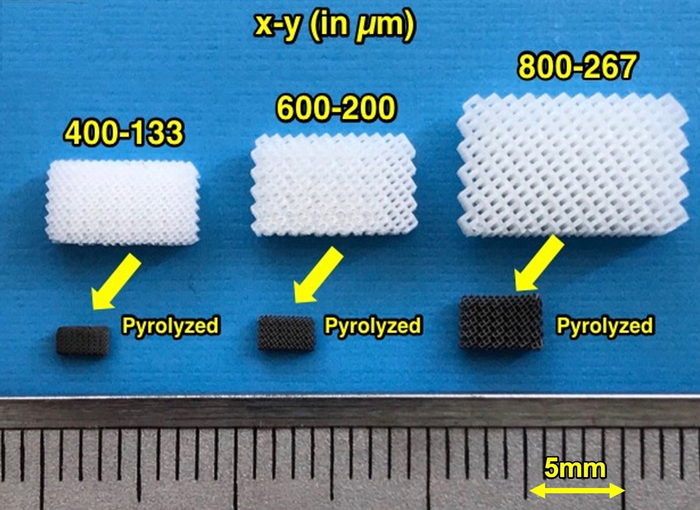

The researchers have addressed this by developing an approach that fabricates micro-engineered, high performing anode, using 3D stereolithography to print microlattice structures made from resin. The microlattices are then shrunk by carbonizing them via a process known as “pyrolysis.”

The resulting hard carbon anodes were found to allow fast transportation of energy-generating ions. Also, as the team made the lattice structure finer, its performance improved.

“As 3D printers gain increasing resolution, sodium ion batteries could eventually outperform lithium-ion ones,” said Akira Kudo, a Tohoku University materials scientist.

The team’s next goal is to use the same approach to make the cathode, and eventually use the finely architected electrodes for superior sodium ion batteries.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Good and sensible to know that microcompartmentalized one size or another, they shrink by 4/5 on each side! Troubles for reinforcing ya’ wind turbine or airframe parts without starting all-carbon at the get go.

Dunno about making the sodium batteries structural with the 3D printing routine, but this necessary battery performance part is good to see.