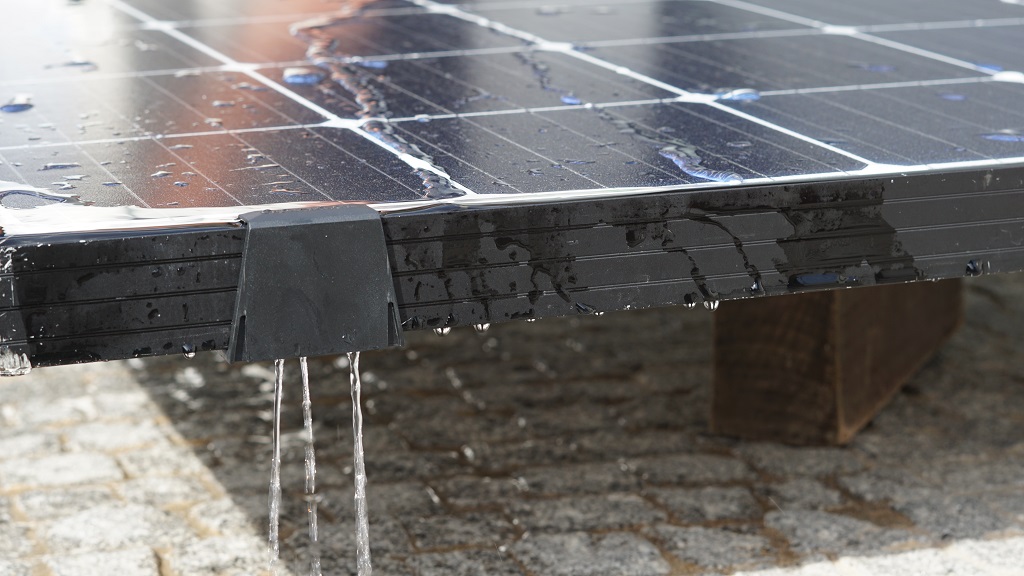

Portuguese startup Solarud has launched a new version of its water-draining device. The new model can be clipped to solar modules to resolve dust and soiling issues.

After the launch of the original device in May, the company listened to customer feedback to develop anti-clogging technology.

“In extreme environments like deserts or arid environments with low humidity, once the first rainfalls fell, or during early morning condensation, the device would get clogged,” António Neves, the co-founder of Solarud, told pv magazine.

Accumulated soiling can lead to clogging in residential installations, with the devices requiring cleaning after a few months.

The company's Solarud Nextgen solution features the company’s patented anti-clogging design to address this issue. It claims energy gains of 3.5% on average with the original device, and expects even better results with the Nextgen, although it has yet to start testing the design.

The product is also more adaptable to different module sizes than its predecessor. The original device worked with frame heights of 30 mm, 35 mm, and 40 mm.

“The new device can adapt to any measure between 30 mm and 40 mm. The tabs are no longer broken [to adapt to the intended measure] but are rather folded. This folding gives them a spring effect, thereby adapting to different heights,” said Neves.

The new device can thus adapt to frame heights of 32 mm and 38 mm, which are standard in the industry. The company has switched from industrial 3D printing to using injection molding for the Nextgen. The switch has “increased the production factor by almost 20 times, and has also allowed for creating more robust devices,” said Neves.

Popular content

It is offering a six-year warranty for the Nextgen – a four-year improvement on its predecessor. The new device is also cheaper, and is available for bulk purchases, starting at 50 units for €99.50 ($96.61), or €1.99 per piece, plus VAT and shipping costs. The original device is no longer manufactured or available for purchase.

The company has also launched nano and custom-made versions of the device, both featuring the anticlog design. The Solarud Nano, with a base of less than 10 mm, compared to the Nextgen’s 22 mm, is designed for installations with very small gaps between modules, up to 10 mm.

The Nextgen and the Nano devices can only be adapted to frames with thicknesses between 8 mm and 11 mm, but the Solarud Custom can be made to measure.

“We have been asked for devices with 13 mm and 15 mm thickness, especially from costumers in Australia, so we decided to create a service of custom-made devices,” explained Neves. “The clients send us the modules’ datasheet, we design the device to fit the specifications, send the costumers some samples, and if they are satisfied, they can then order the devices on our website.”

Both the nano and custom devices are 3D printed and are available for bulk purchases starting at €2.49 per unit, plus VAT and shipping costs. The company develops and produces all the devices in Portugal and has an international client base focused in Europe and Germany, in particular.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.