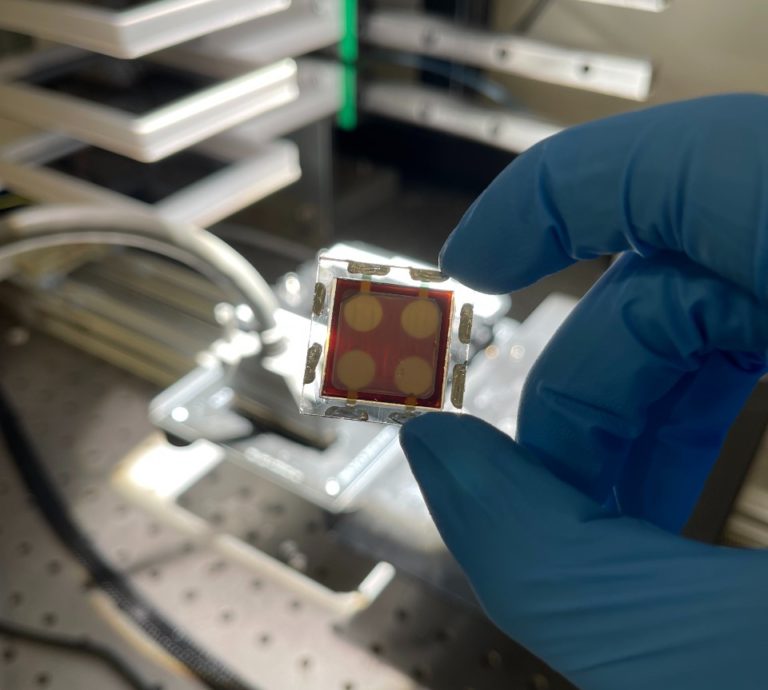

Scientists from the University of Oxford, Monash University and the US National Renewable Energy Laboratory (NREL) have developed a new way to create stable perovskite solar cells with fewer defects – edging closer to the durability of silicon.

The academics removed the solvent dimethyl-sulfoxide from the commonly used dimethyl-formamide/dimethyl-sulfoxide (DMF/DMSO) solvent preparation method. They introduced dimethylammonium chloride (DMACI) as a crystallization agent instead, creating a fabrication method they called DMF/DMACI.

They claim that this allowed them to more effectively control the intermediate phases of the perovskite crystallization process, including texturing, orientation, and the crystallinity of the perovskite.

“By utilizing DMACl as a crystallization agent, we can gradually transition via the hexagonal face-sharing perovskite polytypes (2H, 4H, 6H) toward a 3C corner-sharing perovskite, resulting in highly crystalline and textured thin films with a face-up perovskite unit cell orientation,” the scientists explained.

They subjected 138 sample devices to accelerated aging and testing processes at high temperatures. The formamidinium-caesium perovskite solar cells created with the DMF/DMACI process reportedly outperformed the control group and demonstrated resistance to thermal conditions, humidity, and light degradation.

The best device operated above the T80 threshold for over 1,400 hours under simulated sunlight at 65 C, where T80 is the time it takes for a solar cell to reduce to 80% of its initial efficiency. Beyond 1,600 hours, the control device fabricated using the conventional DMF/DMSO method stopped functioning, while devices fabricated with the DMF/DMACI design retained 70% of their original efficiency, under accelerated aging conditions.

Popular content

The scientists performed the same degradation study on a group of devices at 85 C, with the new cells again outperforming the control group. They determined that the new cells age by a factor of 1.7 for each 10 C increase in temperature, which is close to the twofold increase expected with commercial silicon devices.

“I think what separates us from other studies is that we've done a lot of accelerated aging. We've aged the cells at 65 C and 85 C under the whole light spectrum,” said David McMeekin, a scientist at Oxford University.

Using 138 prototypes in the study is also significant, according to McMeekin.

“Most studies only show one curve without any standard deviation or any kind of statistical approach to determine if this design is more stable than the other,” he said.

The researchers said they expect additional improvements by gaining a better understanding of the intermediate phases of perovskite crystallization “and the mechanism by which they impact the crystallization kinetics and grain orientation of perovskite films.” They described their findings in “Intermediate-phase engineering via dimethylammonium cation additive for stable perovskite solar cells,” which was recently published in Nature Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.