From pv magazine USA

Agrivoltaics – the practice of co-locating solar facilities with cropland – is increasingly being adopted throughout the world as a way to introduced distributed clean energy while not compromising land use.

Research by Oregon State University found that solar and agricultural co-location could provide 20% of the total electricity generation in the United States. Wide-scale installation of agrivoltaics could lead to an annual reduction of 330,000 tons of carbon dioxide emissions while “minimally” impacting crop yield, the researchers said.

The paper found that an area about the size of Maryland would be needed if agrivoltaics were to meet 20% of U.S. electricity generation. That’s about 13,000 square miles, or 1% of current U.S. farmland. At a global scale, it is estimated that 1% of all farmland could produce the world’s energy needs if converted to solar PV.

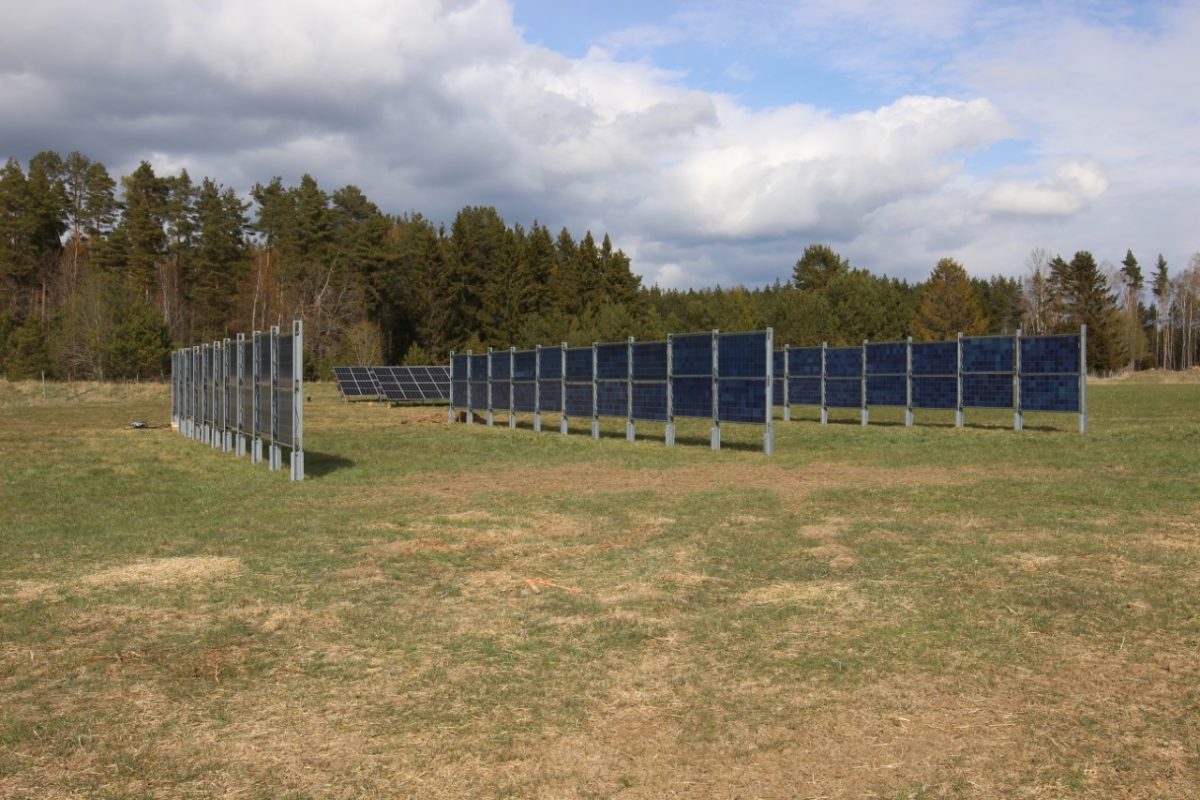

There are many different ways to install agrivoltaic arrays. One common method is to raise the array to leave space for farming equipment or livestock to move freely below. Another trending design is to orient the PV arrays vertically, leaving wide open spaces in between the array rows.

United States

In Somerset, California, German-designed Sunzaun vertical solar arrays were installed at a vineyard. Installer Sunstall developed the facility, which was composed of 43 450 W modules connected to a microinverter and two batteries.

The minimalistic design used holes in the module frames to make a simple attachment to two piles, negating the need for a heavy racking system. The bifacial solar modules produce energy on both sides of the vertically oriented array.

In traditional systems designed with a landscape orientation, the rails used to mount panels onto the racking system are often cut to fit the expected panel size. If the size of the panel changes after all other component procurement has been completed, the project may face delays while the rails are reengineered to fit the updated panel size. Sunzaun’s design allows for easy adaptation to a change in panel size by adjusting the distance between each pile. It is also possible to adjust the height of the panels from the ground if needed.

Germany

Scientists from the Leipzig University of Applied Sciences have looked at the potential impact of deploying vertical west-east oriented PV systems on a massive scale in the German energy market. They have found that such installations could have a beneficial effect in stabilizing the country’s grid, while allowing greater integration with agricultural activities than with conventional ground-mounted PV plants.

The scientists found that vertical PV systems can shift solar yield into hours of higher electricity demand and more electricity supply in the winter months, thus reducing solar curtailment.

“If electricity storage of 1 TW charging and discharging power and 1 TWh capacity is integrated into the energy system model, the effect is reduced to CO2 savings of up to 2.1 Mt/a with 70% vertical east-west and 30% inclined south facing modules,” they said. “Finally, while it might seem unrealistic for some to achieve a rate of 70% vertical power plants, even a lower rate has a beneficial impact.”

Japan

In Japan, Luxor Solar KK, a subsidiary of German module manufacturer Luxor Solar, built an 8.3 kW vertical PV system in the parking area of a rice processing factory owned by Eco Rice Niigata.

“The cars will be parked between the vertical rack systems,” Luxor Solar KK CEO Uwe Liebscher told pv magazine. “The goal of this system is to show the durability during winter, and the additional energy yield due to the reflection of the snow. Niigata, on the other hand, is known for being a high snow load area, with up to 2 meters to 3 meters of snow in winter.”

pv magazine print edition

The south-oriented system features Luxor Solar’s own heterojunction solar modules, as well as mounting systems from German vertical PV specialist Next2Sun and inverters from Japan’s Omron. The vertical array will supply electricity to a rice processing factory next to the system. The city of Nagaoka supported the project with JPY 2 million ($14,390).

“A vertical installation uses only a minimum space of the farmland while maintaining more than 85% of the light reaching the crops, ensuring an optimal balance of solar and farming, which is crucial in Japan,” he said. “This allows us to build agrivoltaic systems on utility crops farmland, like for wheat, potatoes or rice, on a big scale.”

France

In France, TotalEnergies and agrivoltaics specialist InVivo commissioned a 111 kW vertical agrivoltaic demonstrator. TotalEnergies said the pilot facility will investigate the impact of solar panels on agricultural yield, as well as the biodiversity, carbon storage, and water quality of the site.

“We are convinced that the synergies developed between the production of green electricity, biogas and agriculture are one of the answers to guarantee our energy independence and our food independence,” said Thierry Muller, managing director of TotalEnergies Renouvelables France.

Sweden

Scientists at Mälardalen University in Sweden have developed a computational fluid dynamics (CFD) model that facilitates the analysis of microclimates in vertical PV projects. CFD simulations are used to solve complex equations about the flow of solids and gases through and around bodies, which can be used to analyze microclimates within agrivoltaic systems.

“Models of agrivoltaic (AV) systems will become frequently used for new AV system designs as well as decision-making as you can analyze/predict the microclimatic changes dependent on location and AV system solution,” researcher Sebastian Zainalli told pv magazine.

The study observed a 38% decrease in solar radiation intensity in the ground areas shaded by the vertical PV modules.

Key principles

The United States National Renewable Energy Laboratory offered five principles for success in agrivolatics, which included:

- Climate, Soil, and Environmental Conditions — The ambient conditions of a location must be appropriate for both solar generation and the desired crops or ground cover.

- Configurations, Solar Technologies, and Designs — The choice of solar technology, the site layout, and other infrastructure can affect everything from how much light reaches the solar panels to whether a tractor, if needed, can drive under the panels. “This infrastructure will be in the ground for the next 25 years, so you need to get it right for your planned use. It will determine whether the project succeeds,” said James McCall, an NREL researcher working on InSPIRE.

- Crop selection and Cultivation Methods, Seed and Vegetation Designs, and Management Approaches— Agrivoltaic projects should select crops or ground covers that will thrive under panels in their local climate and that are profitable in local markets.

- Compatibility and Flexibility — Agrivoltaics should be designed to accommodate the competing needs of solar owners, solar operators, and farmers or landowners to allow for efficient agricultural activities.

- Collaboration and Partnerships — For any project to succeed, communication and understanding between groups is crucial.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Structure requirements can be further reduced by allowing to pivot about the top edge in winds. Agrisoltaics.com .

I feel that vertical PVs are a great idea. This article highlights some of the benefits of vertical PVs. Some examples of the benefits include allowing for easy adaptation to a change in panel size and shifting solar yield into hours of electricity supply in the winter months. Vertical PVs seem like they would be more ideal than the traditional PV systems because of these benefits. One of the types of vertical PVs mentioned in this article is bifacial PVs. Bifacial PVs produce energy on both sides of a vertically oriented array. I feel that bifacial PVs are more ideal than monofacial PVs, or PVs that produce energy on one side of a vertically oriented array, because bifacial PVs have two sides and that means there is more opportunity to produce energy.

The idea of vertical PV is very interesting. Only small areas in farmlands or parking lots are used to generate electricity through the panels. Moreover, vertical PV is beneficial since it can generate power even in winter. The bifacial solar module seems to be advantageous as it can detect sunlight from both sides, increasing power generation. As Thierry Muller said, I also believe that vertical PV will guarantee us energy independence and food independence.

Every article I read indicates problems converting solar power to something truly useful and/ or marketable. I do not need to power my phone or security lights. It need it to power HVAC, washer, dryer… high voltage items. I need to sell the power to APG&E. I have the rural land and ability to build a grid. Tell me how to use Solar and I will pursue to matter. It all sounds like futuristic idealism