Thermal energy storage systems use temperature shifts to store energy for later use, or for use at other locations. The most commonly used ways to capture energy are based on latent and sensible heat transfers.

The former heat method uses the amount of thermal energy needed for a phase change – which is a change in physical state, such as from solid to liquid, or liquid to gas – without altering the temperature of a material. This technique is associated with large energy densities. The latter is the thermal energy required to raise the temperature of a material without causing any phase transitions. A major advantage of this heat transfer method is its low cost.

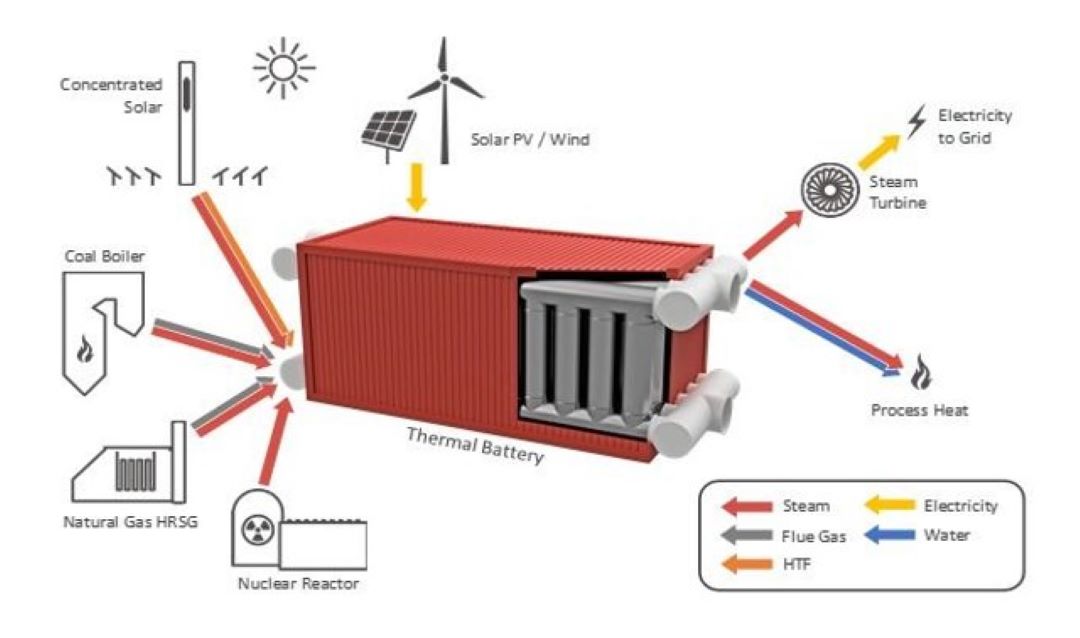

Now, engineers at Lehigh University in Pennsylvania, with support from the US Department of Energy, have developed a new thermal energy system that combines the best of both techniques. The Lehigh Thermal Battery consists of engineered cementitious materials and thermosiphons in a combination that enables fast, efficient thermal performance at low cost. The technology can operate with heat or electricity as the charging energy input.

The team has announced that, after three years of research and development, the Lehigh Thermal Battery is now market-ready. The process involved integrated system testing at 3, 10 and 150 kilowatt-hours thermal (kWhth) in a relevant environment.

The 150-kWhth prototype built at the Energy Research Center is a fully instrumented structure containing 22 finned thermosyphons. The 150-kWhth prototype has been tested extensively using compressed air at 480 C, producing an energy-to-energy charge/discharge efficiency of the solid media of more than 95%, uniform temperature distribution in the solid media during charging, and consistent cyclic repeatability.

The average power rates achieved during charging and discharging were 16.4 kWth and 19.8 kWth, respectively, with a very fast energy gradient of the thermal battery of 0.51 kWhth/min during the first hour of discharge.

Co-principal investigator Sudhakar Neti, professor emeritus in the Department of Mechanics and Mechanical Engineering at Lehigh, claimed that the technology is innovative on many levels.

“It is modular, designed for independent energy input/output streams during charging/discharging, which is feasible with the help of the thermosyphons, and the two-phase change process inside the thermosyphon tubes allows rapid isothermal heat transfer to/from the storage media at very high heat transfer coefficients and heat rates,” said Neti.

Carlos Romero, co-principal investigator on the project and the director of the Energy Research Center at Lehigh, said that the concrete plus thermosiphon concept is unique among heat energy storage concepts.

“The technology offers the potential for adaptation over a broad range of temperatures, and heat transfer media and operating conditions,” said Romero.

These qualities make the Lehigh Thermal Battery suitable for decarbonization opportunities in energy-intense industry sectors, the flexibilization of conventional power plants, and advancements and penetration of concentrated solar power.

“Another opportunity for the Lehigh Thermal Battery to play an important role in the decarbonization effort is the integration of thermal energy storage in a system that includes heat pumps and Organic Rankine Cycles, working with surplus renewable electricity,” said Neti.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.