Scientists at Germany's Helmholtz-Zentrum Berlin für Materialien und Energie GmbH have developed a new precursor ink technique to improve film quality in halide perovskite solar cells. In the study “Ink Design Enabling Slot-Die Coated Perovskite Solar Cells with >22% Power Conversion Efficiency, Micro-Modules, and 1 Year of Outdoor Performance Evaluation,” which was recently published in Advanced Energy Materials, the researchers said that they used a formamidinium lead triiodide (FAPbI3) precursor ink based on 2-methoxyethanol in the slot-die coating process.

Slot-die is a coating process used to deposit thin and uniform films with limited material waste and low operational costs.

“The slot-die coating is one of the most promising processes enabling sheet-to-sheet, continuous roll-to-roll coating, and solution-processable optoelectronic device technology such as organic electronic devices and polymer solar cells,” the team said, noting the industry commonly uses spin-coating for perovskite cell production.

The researchers said the new precursor ink method is aimed at preventing the so-called ribbing effects that usually arise in perovskite solar devices with slot-die and cause irregular shapes in the deposited wet perovskite films.

“Ribbing is a common effect observed at the downstream meniscus when the viscous and capillary forces between ink, slot-die, and substrate are unbalanced,” they stated.

They adjusted the ink viscosity via acetonitrile (ACN) with a 46% concentration. The compound acted as a co-solvent for the FAPbI3 thin-film and improved its quality and layer homogeneity.

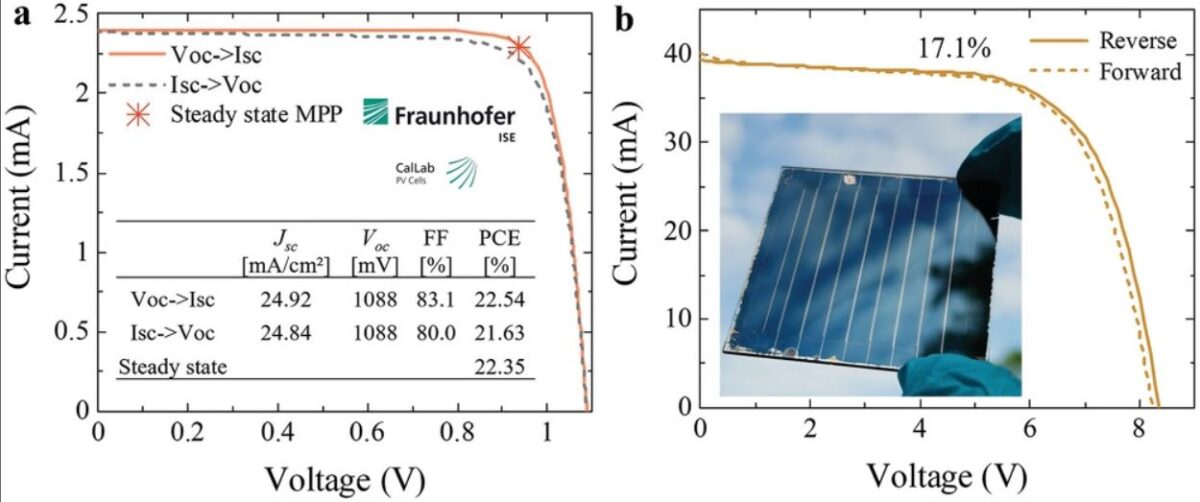

The German group utilized this technique in a small-area solar cell, which achieved a power conversion efficiency of 22.54%, which it said is the highest certified value for a slot-die-coated perovskite solar cell to date. The device also reached an open-circuit voltage of 1.088 V, a short-circuit current of 24.9 mA cm2, and a fill factor of 83.1%. Germany's Fraunhofer ISE CalLab confirmed this result.

The team also built mini-modules with active areas of 12.7 cm2 and an efficiency of 17.1%.

“A full year of outdoor stability testing with continuous maximum power point tracking on encapsulated devices is performed and it is demonstrated that these devices maintain close to 100% of their initial performance during winter and spring followed by a significant performance decline during warmer summer months,” said the researchers.

Looking forward, the academics plan to scale the technology to larger device areas and assess the performance under different long-term exposure conditions.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.