A Brazilian research group has developed a novel recycling method for solar panels that uses supercritical water technology.

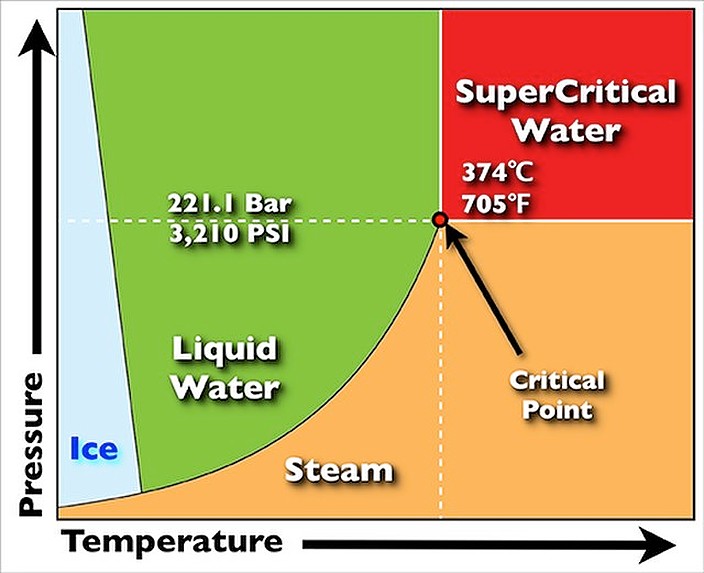

Supercritical water is water heated and pressurized beyond its normal boiling point. In this state, it has unique properties that make it a powerful solvent. “The water reaches the supercritical state when the temperature and pressure exceed 374.3 C and 22.1 MPa, respectively. Its physicochemical properties are quite different in this state, promoting the decomposition of hazardous and persistent organic compounds,” the researchers explained, noting that the proposed process does not require toxic or hazardous chemicals.

With the new method, solar cells are first broken into smaller pieces, and placed in a reactor. That reactor is constantly fed with water that is being heated and pressured to a supercritical state. This process results in gaseous, liquid, and solid products.

In order to assess the organic degradation rate of the panels, the academics have tested the method with varied temperatures, flow rates, reaction times, and solution compositions. Then, running a further optimization method, the group achieved a 99.6% organic degradation rate at 550 C, with a reaction time in the reactor of 60 minutes, a volumetric flow rate of 10 mL/m, and a feed solution composed of an aqueous solution of residual organic compound and hydrogen peroxide (H2O2/Rorg).

“The aqueous solution of residual organic compounds, composed of methanol, acetonitrile, and chloroform, was obtained from high-performance liquid chromatography (HPLC) analyses,” they emphasized. “The processing of waste solar panel under supercritical conditions was conducted to evaluate the possibility of the simultaneous treatment of solid waste and organic liquid wastewater, decreasing the amount of clean water consumed.”

Regarding solid products resulting from the method, through the different supercritical conditions, an average metal recovery efficiency of 76% was observed. Among the metals recovered were aluminum, magnesium, copper, and silver. “This recovery possibility makes the process more economically attractive,” they added.

Popular content

As for the gaseous byproducts, their mean composition using H2O2/Rorg was 72.9% carbon dioxide, 18.6% hydrogen and 8.6% nitrogen. “The obtained results highlight one of the supercritical water technology main advantages, that is, the possibility to use wastewater for the treatment of electronic waste producing only non-harmful gases in a controlled environment,” the scientists stressed.

The liquid byproduct produced in this recycling method mainly consisted of phenolic derivatives such as 3-ethylphenol, bisphenol A, and 4-isopropylphenol. This new byproduct can then undergo another treatment via supercritical water technology, removing almost 100% of the total organic carbon. “This allows the reuse of the liquid outputs in several treatment processes of solar panel waste,” the Brazilian group added.

Finally, the academics have proposed an energy-integrated superstructure design for a scaled-up recycling process. The proposed method for industrial-scale recycling includes a quench unit, flash tank, and fired heater, among other parts. Using simulation software, the scientists found the superstructure to have a 59.2% reduction in the hot utilities requirement and a 60.2% reduction in the cold utilities requirement, compared to a direct scale-up of the experimental setup. In addition, an operating cost reduction of 60.5% was observed.

The proposed approach is presented in the paper “Simultaneous recycling of waste solar panels and treatment of persistent organic compounds via supercritical water technology,” published in Environmental Pollution. It was written by scientists from the State University of Maringá, the Federal University of Goiás, and the University of Sao Paulo.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Hello, I have worked on SC water for long time and recycling of electronic components (ICs and circuit boards). Depending on temperature and residence time, different chemicals can be obtained at the exit. Energy consumlption can also be drastically reduced with some tricks.