Researchers at Durham University in the United Kingdom have proposed a new design for thermoelectric heat pumps (TeHPs) that reportedly exploits all the advantages this heat pump technology offers, especially when applied in residential buildings.

They explained that TeHPs can be powered by PV panels directly, while offering silent operation and high reliability, due to the absence of moving parts. They also acknowledged, however, that their coefficient of performance is currently lower than that of conventional vapor compression heat pumps.

The novelty of the proposed approach consists of integrating the TeHP with seasonal solar energy storage (SSES), which the scientists said compensates for the seasonal mismatch related to the thermal power eventually produced by both photovoltaic-thermal (PVT) and solar thermal systems.

“To the best of our knowledge, few studies have considered such a solution,” they explained. “Our group aims to fill this gap, and to do so, two important issues must be solved,” they said referring to the technical-economic feasibility of the system and the quantification of the benefits it can provide.

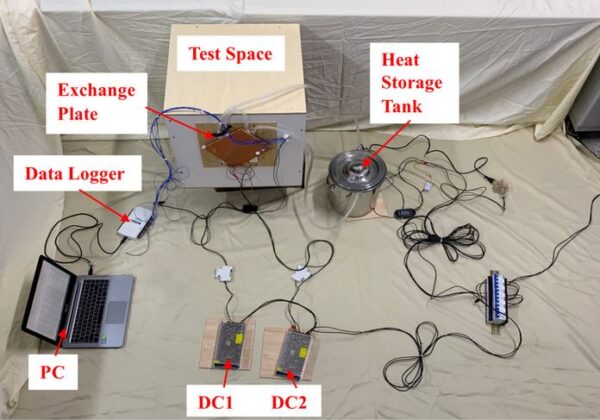

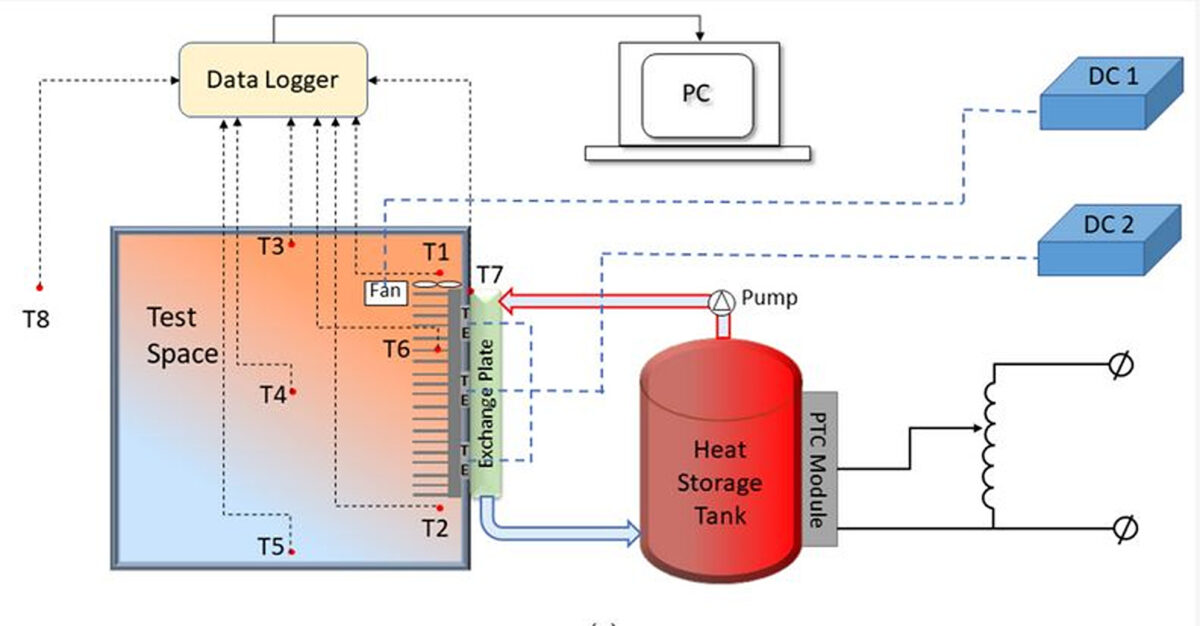

In the paper “Modeling and Experimental Characterisation of a Water-to-Air Thermoelectric Heat Pump with Thermal Energy Storage,” published in energies, the research group said the DC-powered experimental system integrates a TeHP unit, a heat storage tank, a testing box, and a data logger system. The TeHP unit is based on a thermoelectric module (TeM), an aluminium-finned heat sink at the hot side of the TeM, and a water-cooled plate at the cold side of the TeM.

Image: Durham University, energies, Creative Commons License CC BY 4.0

“The total heating capacity of the TeHP unit can be augmented by simply increasing the total number of the TeMs,” the academics explained. “To enhance the heat transfer between the TeM and the heat sink as well as the heat transfer between the TeM and the water-cooled plate, a high thermal conductance paste was placed at the two sides of the TeM to reduce the contact thermal resistances.”

They also placed a cross-flow fan on the heat sink side to enhance the heat exchange between the airflow and the heat sink. “The heat storage tank, made of stainless steel, features an inner diameter of 25 0mm, a height of 250 mm, and a thickness of 2 mm,” they added, noting that water is used as heat transfer fluid and heat storage medium. Furthermore, a pumped water circulation loop connects the heat storage tank with the water-cooled plate.

Popular content

In a series of simulations implemented via the TRNSYS simulation tool, the research team calculated the potential heat generated from PVT systems or solar thermal collectors and the output performance of the TeHP unit compared to a reference system without heat storage. It found that the integration of TeHPs with heat storage tanks offers three main advantages.

First, the academics ascertained that the storage tank increases the TeHP heat output by 3 C compared to the TeHP without a tank. Then, they found that the COP of the TeHP with heat storage was 1.97 and that of the TeHP without a tank was 1.5. Furthermore, the simulation showed that the time required to heat the testing box was reduced by 18 m, which reportedly ensures a rapid achievement of the desired temperature.

The scientists said that, although these results are promising, the technical-economic feasibility of the system is still uncertain. “This is because, though the use of heat storage will enhance the output performance of the TeHP, it will also introduce additional costs for the heat storage facilities compared with a standalone TeHP,” they emphasized, noting that the current payback period of the system is estimated at 8.5 years.

Looking forward, the research group intends to test the system configuration on a real building in the United Kingdom.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

If I understand this it is something I have been toying with in my head. Can I provide more heat to a heat pump using thermal solar panels?

Terrible CoP but over 1. I thought it would be used as a kicker for a heat pump with a working fluid, or thermovoltaic generation.