An international research group sought to address one of the commercialization challenges of perovskite solar cells, maintaining high efficiency when scaling up from the cell-to-module level.

“Transitioning from laboratory-scale cells to larger modules poses a notable efficiency loss,” the research's lead author, Yi Yang, told pv magazine. “The highest certified stabilized aperture-area efficiency for perovskite solar modules exceeding 30 cm2 in area has recently been observed to plateau at approximately 19.5%. This comes in part from defects that arise during solution processing.”

Additives used in prior research tended to aggregate within the perovskite film during co-precipitation in the course of solvent evaporation, according to Yang. “This led us to formulate a hypothesis: exploring alternative processing methods beyond the commonly used evaporative precipitation and crystallization could potentially decrease defects and the presence of insulating inclusions,” said Yang.

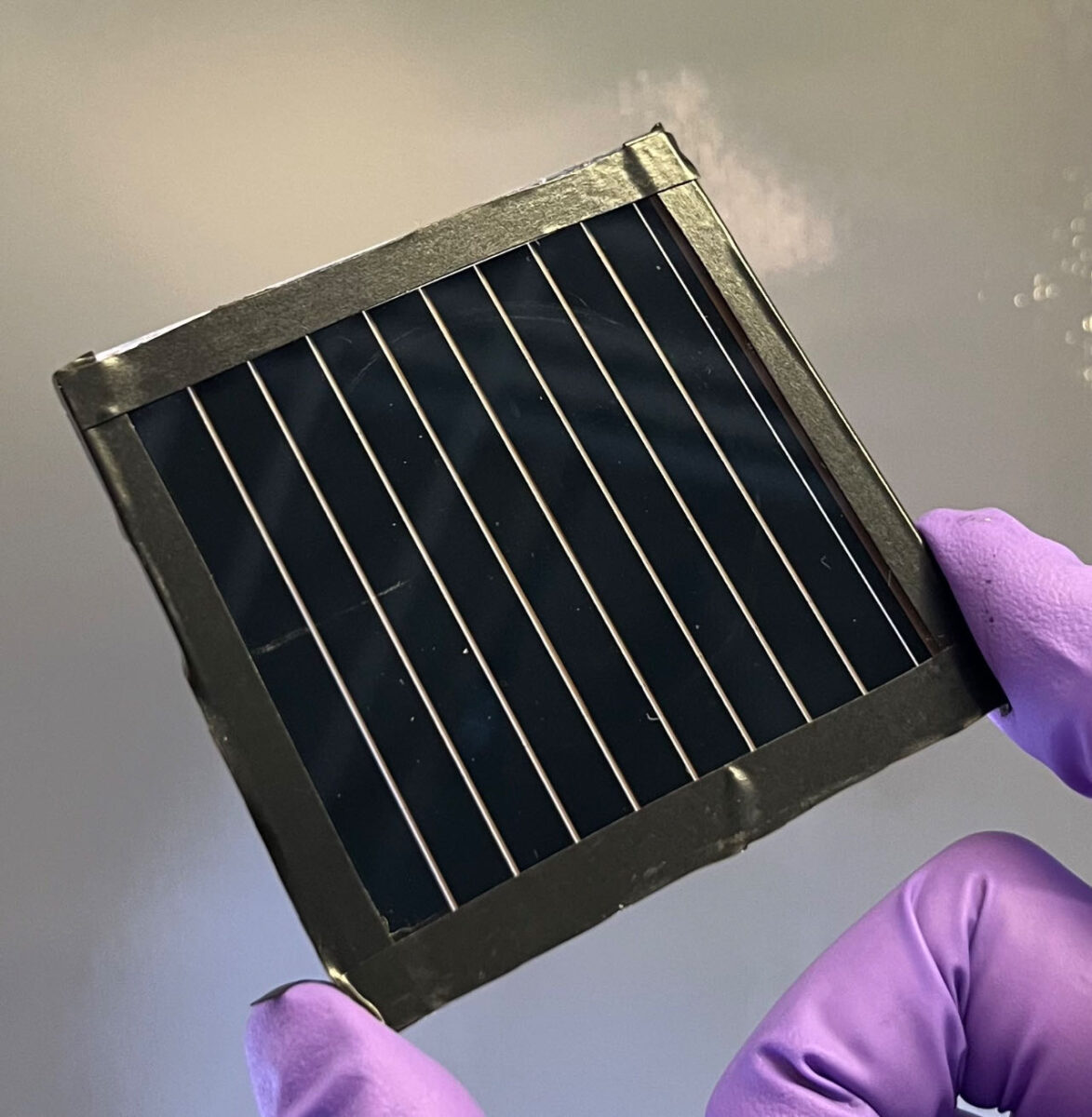

The academics utilized thermotropic liquid crystals to avoid the evaporative precipitation of conventional additives and the typical interface accumulation to enable uniform passivation of the large-area perovskite films. “The approach achieved a fast scan efficiency of 21.8% and stabilized efficiency of 21.1% for 30 cm2 perovskite mini modules with enhanced stability,” said Yang.

Specifically, the team worked with thermotropic liquid crystals, such as 3,4,5-trifluoro-4′-(trans-4-propylcyclohexyl)biphenyl (TFPCBP), embedding the material into the large-area perovskite films.

The cells were fabricated in an n–i–p configuration, employing a fluorine-doped tin oxide (FTO) substrate, an electron transport layer (ETL) based on a buckminsterfullerene (C60) and tin(IV) oxide (SnO2), a perovskite absorber, a Spiro-OMeTAD hole-transporting layer, and a gold (Au) metal contact.

Popular content

The perovskite solar modules consisted of six and nine sub-cells connected in series on 5 cm × 5 cm and 6.5 cm × 7 cm substrates, respectively.

The team selected thermotropic liquid crystals because of their “characteristic mesomorphic phase transition from a solid to an isotropic liquid phase when heated.” They remain in the liquid phase while the perovskite solidifies. “The efficient diffusion within a mixed liquid-solid system enabled TFPCBP molecules to distribute uniformly throughout the film for a homogenous passivation of defects,” said Yang.

The academics conducted several standards-based stability tests of the treated cells and modules, including reverse bias tests, and found superior stability results. For example, the damp-heat stability of encapsulated modules was tested using the ISOS-D-3 procedure, subjecting them to 85% RH at 85 C. “The TFPCBP-based modules retained 86% of their initial efficiency after 1,200 h, compared with 51% retention for the control,” noted the researchers, adding that it “represents the longest-lived damp-heat stability in literature among n–i–p perovskite solar modules.”

The team sees the potential to transfer the technology to slot-die coating processes to fabricate larger-area perovskite sub-modules. In addition, Yang sees opportunities for further exploration of the functionality and phase structure of liquid crystal molecules to improve passivation effects and device stability.

Their findings are available in the study “A thermotropic liquid crystal enables efficient and stable perovskite solar modules,” published in Nature Energy. The scientists came from Northwestern University, the Swiss Federal Institute of Technology Lausanne, North China Electric Power University, the University of Toronto, and the US Department of Energy's Argonne National Laboratory.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.