Researchers at Hebei University of Science and Technology in China and Riken Center for Advanced Photonics in Japan demonstrated a novel silver ion solution-assisted femtosecond laser process for glass-to-glass welding with the purpose of eventually applying it to solar cell packaging.

The team demonstrated the strength of the joined glass package with solar cell chips between welded glass samples that continued to operate underwater.

Glass-glass welding is one of several edge sealant packaging methods, along with novel adhesives, proposed to enable solar PV device durability and reduce costs. It is also seen as an enabler of effective solar panel recycling.

Femtosecond lasers are a type of infrared laser that delivers fast, single laser pulses. Femtosecond lasers are widely used in medical eye procedures like cataract surgery.

In their paper, “Femtosecond laser photochemical reduction of silver ion solution for micro-welding of transparent and hard materials for solar cell packaging,” published in Materials & Design, the scientists describe why a solution for high-quality connections of solar packaging materials is needed, and how the novel silver ion solution provided an intermediate layer, enabling femtosecond laser micro-welding of glass and heterogeneous materials.

The results showed that the photochemically reduced silver nanoclusters that were used in the solution increased the shear strength of glass to 27.36 MPa at a low input energy density (2.4J/cm2). The silver ion solution improved energy utilization efficiency, suppressed the formation of welding cracks, and increase the suitability of liquid-layer-assisted femtosecond laser welding, according to the research team.

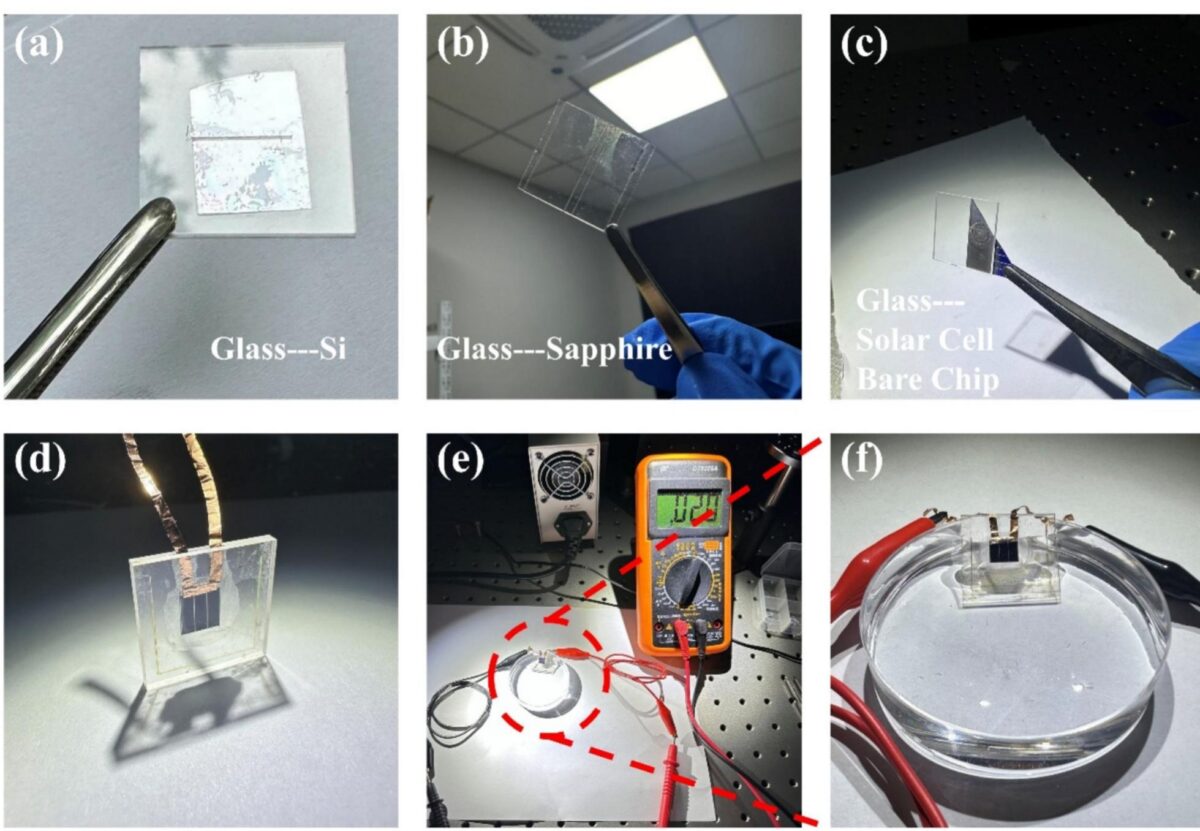

Monocrystalline silicon and sapphire were also welded as representative of semiconductor and optical materials with distinct thermophysical properties. “Despite the material property mismatches, a successful heterojunction was achieved through fs laser welding,” said the research group.

The experimental samples were as follows: commercial silica glass measuring 20 × 20 × 1 mm3, sapphire glass measuring 20 × 20 × 1 mm3, and single-crystal silicon 10 × 10 × 0.33 mm3. The laser was a Pharos PH2-20 W system.

The team then tested the the sealing with a solar silicon cell chip. The encapsulated photovoltaic device was made with a quartz glass substrate an conductive adhesive tape contacts. It was placed in water. To enable electrical signal monitoring, the top interface of the sealed structure remained intentionally unwelded.

“The packaged solar cell chips retained their conductivity in water. These findings indicate that the silver ion solution interlayer-assisted femtosecond laser welding process enables the formation of high-strength connections while effectively mitigating the impact of moisture and other extreme environmental factors on the performance of solar devices,” noted the researchers.

The reliability of the method was further validated through thermal shock and water seal testing, reportedly achieving compliance with the IPX7 waterproof standard and IEC 60529:2013.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.