A German research team has investigated the use of zeotropic fluid mixtures as the working fluid in high-temperature heat pumps (HTHP).

Zeotropic mixtures consist of two or more fluids with varying boiling or condensing temperatures at a given pressure. These fluids exhibit temperature glide, which is a range of temperatures over which the mixture evaporates rather than a single constant temperature.

“This study's objective is to enhance the efficiency of high-temperature heat pumps, specifically for delivery temperatures reaching up to 170 C,” said the researchers. “This improvement is pursued by utilizing either a pure working fluid or a combination of fluids with high and medium critical temperatures. The novelty of this study lies in the investigation of high supply temperatures in the range of 140 C and 170 C.”

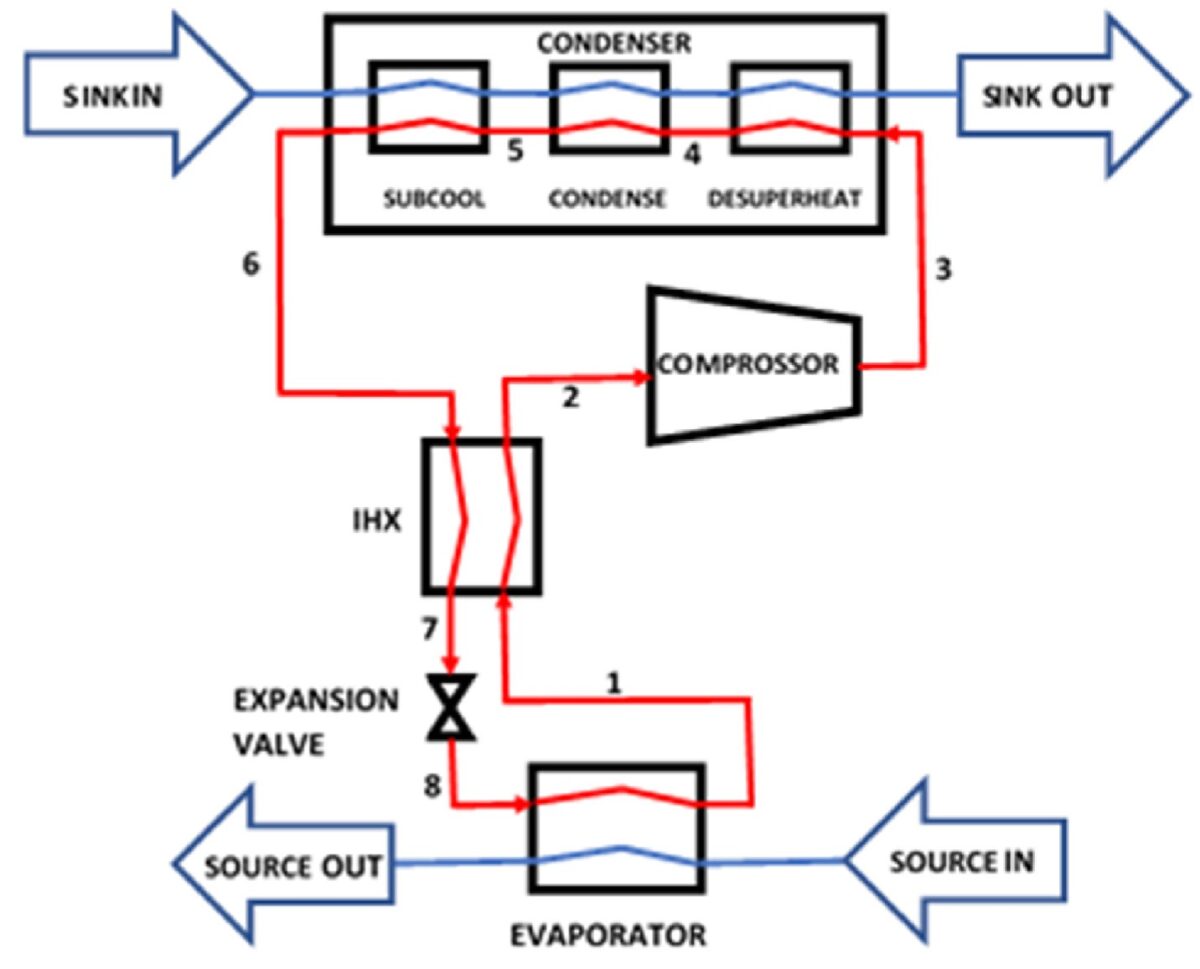

To investigate the different working fluids, the academics have simulated an HTHP with the Aspen Plus software. The HTHP system configuration was based on a vapor compression cycle and built with five components: condenser, evaporator, compressor, expansion valve, and internal heat exchanger (IHX).

Two categories of fluids were selected as the working fluids, either alone or as a mixture. In the first category, all fluids had a high critical temperature above 200 C. The selected fluids were hexamethyldisiloxane (MM), cyclohexane, and cyclopentane. The second group was of fluids with a medium critical temperature of 100 C – 200 C, which included butane (R600), isobutane (R600a), pentane (R601), isopentane (R601a), cyclopropane, R1336mzz(Z), R1234ze(Z), and R1233zd(E).

“The choice of working fluids is informed by a few factors which cut across environmental, safety and application factors. The environmental factors considered are the ozone depletion potential (ODP) and global warming potential (GWP), while the safety class covers the toxicity and flammability of the fluids,” the group clarified.

Popular content

The simulation showed that the cyclohexane/cyclopropane mixture with a 0.9 mol fraction of cyclohexane had the highest coefficient of performance (COP): 2.81 for supply temperatures at 170 C. “This mixture improved the efficiency of the HTHP, with the obtained COPs higher than those of standard working fluids like R601a and R1233zd(E) by 7.16% and 7.19% respectively at 140 C supply temperature,” added the researchers.

The cyclohexane/cyclopropane mixture reached a critical temperature of 265.07 C, which is far above the 204.43 C compressor discharge temperature (CDT) of the system at 170 C supply temperature. “The aim of attaining a mixture with high critical temperature and consequently having an overall subcritical operation was met,” they asserted.

The simulation also showed that the internal heat exchanger pinch point temperature difference had an effect on the performance of the system. “An increase in the heat source temperature difference from 5 to 20 K decreased the COP of the cyclohexane/cyclopropane (0.9/0.1) mixture by 4.32% and 7.47% for 140 C and 170 C supply temperatures, respectively,” the academics stated.

The study's results were presented in “Thermodynamic analysis of novel mixtures including siloxanes and cyclic hydrocarbons for high-temperature heat pumps,” published in Energy. The research was conducted by scientists from Germany's University of Bayreuth and Nigeria's Nnamdi Azikiwe University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.