Increasing volumes for PV module recycling in Brazil

Brazilan PV module recycling specialist SunR has already recycled 30 tons of panels and expects to receive another 125 tons. According to its CEO, demand for recycled panels, especially broken panels, has increased considerably in recent years.

Jetion Solar setting up 5 GW heterojunction PV module factory in China

Construction on the new factory is scheduled to begin by the end of the year and manufacturing activities should begin in 2023.

ICRA offers stable outlook on India’s renewable energy sector

The forecast is supported by a strong project pipeline, competitive tariffs, and continued policy support. The demand outlook for domestic solar module manufacturers also remains favorable.

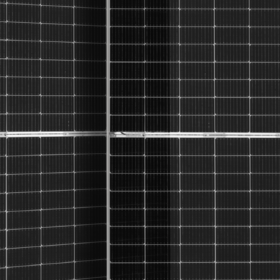

JinkoSolar unveils details of its TopCon 620 W bifacial solar panel

The Tiger Neo panel has a power conversion efficiency of up to 22.1% and a temperature coefficient is -0.30% per Celsius degree. The product is made with 182mm wafers, half-cut cells, and has a power output ranging from 590 to 620 W.

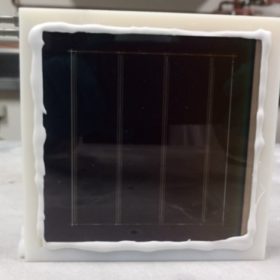

Cooling solar panels with thermoelectric modules

The cooling system was made with an aluminum heat sink and a thermoelectric module. The solar panel is cooled exclusively by the thermoelectric device, which is, in turn, cooled down by the heat sink via free convection. According to the scientists that developed the technique, it was able to reduce panel operating temperature by about 10 degrees Celsius.

Chinese PV Industry Brief: Shandong province wants to deploy another 35 GW of PV over the next five years

In addition, JA Solar was able to ship 10 GW of modules in the first six months of the year and raise RMB5 billion for new production capacity.

Coupling PV-powered electrochemical water splitting with battery storage

A German research team has developed a photovoltaic-electrochemical device for alkaline water electrolysis that can be linked to battery storage. The proposed system configuration can not only smoothen out the PV power fluctuations and facilitate power coupling, but also improve solar to hydrogen efficiency.

Bullish clean energy stocks helped maintain healthy investment levels

The latest renewables investment report produced by analyst BloombergNEF has noted backing for solar projects continued to rise in the first half as wind power investment fell back.

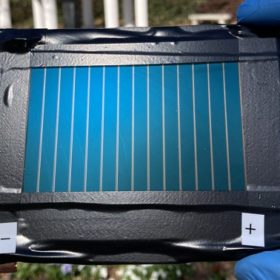

Mini perovskite solar module with 19.2% efficiency via new additive

The efficiency of the module was certified by the U.S.’ National Renewable Energy Laboratory. It was built with perovskite solar cells with a stabilized efficiency of 23.6%, an open-circuit voltage of 1.17 V, a short-circuit current density of 24.1 mA per cm−2, and a fill factor of 0.842.

Green roof improves solar panel efficiency by 3.6% on average

The comparison of two solar cladded roofs in Sydney, Australia, one bare beneath its panels and the other adorned with native grasses and plants, has found the panels on the green roof were, on average, 3.63% more efficient, producing an average daily output 13% greater than the conventional roof. The improvements are believed to stem from the lower temperatures on the green roof, thanks to its plants – which also provided a plethora of additional benefits.