EUPVSEC 2021 – Key takeaways

Now in its 38th year, and its second as a fully virtual event, the 2021 EU PVSEC conference revealed a solar industry and research community filled with confidence. Discussions at the event began with the expectation that demand for solar will continue to grow rapidly, and focused on the challenges of further scaling up production and deployment, and ensuring that energy systems can run smoothly with solar and wind as their main source of energy.

Chinese PV Industry Brief: New alliance for BIPV

Steel manufacturer SSFG and backsheet maker First PV have created a new company to deploy 950 MW of BIPV capacity in China over the next five years. Moreover, China General Nuclear Power Group (CGN) began selling electricity on the country’s green power trading platform and inverter maker Ginlong Solis has decided to team up with State Power Investment Corporation (SPIC).

Cylindrical solar panel for street lighting

Developed by an Italian manufacturer, the panel is available in three versions with a power output of 100, 120, and 240 W and has a weight of 5 kg. It is encapsulated in thermoformable plastic technical polymers and can be connected in series with other modules around the same post.

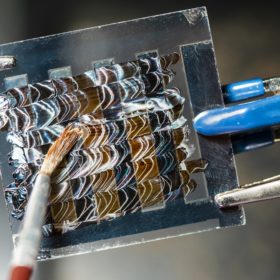

Co-evaporated perovskite solar cell with 20.6% efficiency

Researchers in Singapore have built what they claim is the industry’s most efficient, large-area co-evaporated solar cell. According to their findings, the device has exhibited remarkable thermal stability and could reach commercial maturity within the next few years.

Cooling PV panels with water and cotton mesh

Scientists in Russia have developed an active cooling technique that spreads water on both sides of the module and uses a cotton wick mesh to absorb and spread the water that comes on the rear side. The system is able to reduce significantly a module’s operating temperature and lead to an overall improvement of 30.3% in its output power.

Australian startup sets 25.54% efficiency record for silicon cell

SunDrive said it has created the most effective commercial-sized silicon solar cell in the world, achieving an efficiency figure of 25.54% in testing carried out by Germany’s Institute for Solar Energy Research (ISFH).

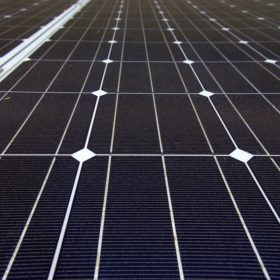

LCOE of monofacial, bifacial solar modules

Does higher energy production outweigh an increase in costs? Clean Energy Associates tries to answer this question in a new case study.

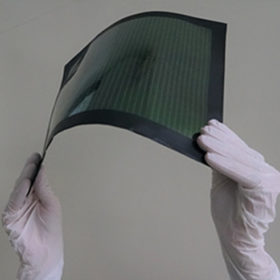

Toshiba claims 15.1% efficiency for polymer film-based large-area perovskite solar module

The result is claimed to be the highest efficiency ever reached for a large-area, polymer film-based perovskite photovoltaic module. The device has an area of 703 square centimeters and was fabricated through a new coating method.

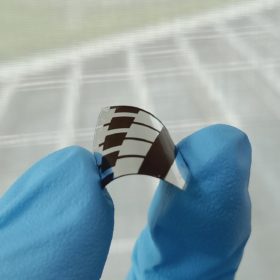

NREL scientists test back-contact architecture on perovskite solar cells

Scientists in the United States explored the use of all back contact architectures for perovskite solar cells. The group notes several advantages to this strategy, as well as challenges to overcome. Ultimately, the work outlines a route to cell efficiencies better than 20%.

JA Solar, JinkoSolar, Longi reach consensus on 182mm module standardization

The three Chinese panel manufacturers found an agreement on the module size and the mounting hole spacing.