PV modules shipping at lower prices in US, EIA data shows

The Energy Information Administration says that more than 2.7 GW of modules were shipped at an average price of $0.34 per watt in March.

GCL auditor resigns over silicon project pre-payment probe

Deloitte has walked away from the polysilicon manufacturer, despite the latter having followed the accountant’s recommendation to appoint a third party to investigate why a near-$80 million payment was made in September 2019. Apparently the parties could not agree the detail of the investigation to be carried out.

Hanwha Q Cells announces n-type module with passivating contacts

Production on the new module, called Q.Tron, is expected to begin this year. The product is described as an evolution of the company’s Q.antum cell technology.

Compressed air tech for solar module cleaning, cooling

British scientists have developed an experimental compressed air system for the simultaneous cleaning and cooling of PV modules. The system was built with a compressed-air unit which was made of a compressor, an air tank, and an airflow regulation valve, and a series of nozzles. The technique was tested on a PV system located in northwestern India.

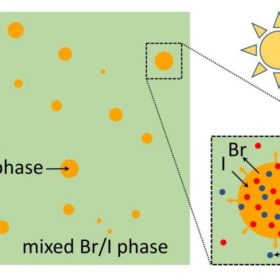

Thermodynamic model to build more-stable perovskite solar cells

Dutch scientists claim to have developed a theory that explains the mechanisms behind halide segregation, which is the main factor affecting thermal stability in perovskite solar cells. They affirmed that the theory may provide technical solutions to build more stable perovskite PV devices.

How will you know it’s green hydrogen?

Australia’s Smart Energy Council says that its new verification scheme for green hydrogen is gaining international traction.

The weekend read: Large-format PV modules – is bigger really better?

Large-format PV modules are a key development in solar technology and advocates say their emergence has the potential to be one of the most significant innovations the industry has ever seen. But many people remain unconvinced that bigger is actually better.

Chinese PV Industry Brief: New 5 GW heterojunction solar module factory, increasing wafer and cell prices

China-based wind turbine manufacturer Mingyang Smart Energy wants to build a heterojunction module factory with a capacity of 5 GW. Both Longi and Tongwei have raised the prices of their wafers and cells, respectively.

New discovery promises to bring singlet fission enhanced C-Si solar cells nearer to commercial production

New research from Australia has shown that singlet fission solar cells do not only have the potential to raise the theoretical efficiency of the PV technology to unexpected levels but also to provide a better temperature behavior and longer duration compared to conventional PV devices. The scientists believe that this technique may help conventional crystalline silicon solar cell technologies reach efficiencies close to 30%.

Daqo opens Xinjiang polysilicon factory to international observers

The polysilicon manufacturer has once again rejected allegations of forced labor by opening the doors of its factory in China’s Xinjiang Uyghur Autonomous Region to international investors and journalists. Video footage of the event was published by the company on its website.