Polish solar manufacturers unite to compete with imports

Businesses, supported by the government, will join forces to strengthen their industry and contribute to the European Green Deal through made-in-EU products.

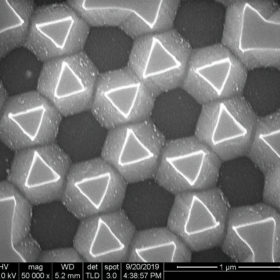

Nanostructures for ultrathin flexible wafer

Scientists in South Korea combined two processes to etch a nanostructure of tiny pyramids onto the surface of a silicon wafer. As well as trapping more light and increasing the cell efficiency, the group claims that its nanostructure improves the mechanical flexibility of the cells. This could potentially allow for the use of much thinner silicon wafers than is currently possible in production.

Cooling PV panels with seawater

An Anglo-Egyptian research group has developed a passive cooling method based on saturated activated alumina, with saline water as a cooling agent.

Chinese PV Industry Brief: New 10 GW module factory planned as 3.6 GW of cell capacity comes online

Power company Datang Group is reportedly planning to spend around $148 million replacing a coal-fired power plant with a 200 MW solar project in Shanxi province and two solar players are set to issue stock.

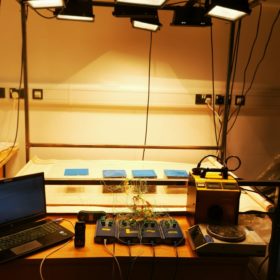

Active cooling for PV modules in floating arrays

Saudi Arabian and Pakistani scientists have created a serpentine cooling block structure to improve the efficiency of PV panels in floating solar projects by around 1.5%. The cooling block can be filled via a low-cost, 15.6 W commercial 12 V DC water pump with cool water.

Photovoltaic shade for greenhouses

French start-up Solar Cloth has secured a patent for a PV shade screen for solar greenhouses.

Keeping PV panels honest

Michelle McCann and Lawrence McIntosh, the partners behind the PV Lab panel-testing facility in Canberra, see Australia’s solar installations as a vast, aggregated virtual power plant.

RENA picks up 15 GW equipment order

Germany based PV equipment supplier RENA Technologies has received what it describes as its ‘biggest ever order’, from a tier 1 manufacturer in Asia, for 15 GW of its wafer texturing equipment. Financial details of the deal have not been disclosed, although the company states that the order is worth “tens of millions of euros.”

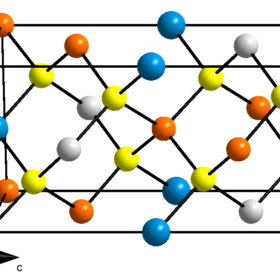

Defect analysis promises kesterite solar cells with 18.47% efficiency

An international research group has found that the presence of a few lattice defects in a kesterite PV cell material can actually improve efficiency, rather than lowering it. The group believes that kesterite PV cells could see mass production within the next decade.

SNEC 2020 CEO Series: Suntech bounces back

Once an industrial solar giant, Suntech has worked hard to rebuild its foundations and regain a solid footing in the global PV industry, following its financial crash in 2013. pv magazine caught up with CEO Tang Jun at this year’s SNEC 2020, held in Shanghai, China, last month, to find out its plans for the future, and how the Covid-19 pandemic has affected operations. Strong global growth and continued multi-crystalline production are two cornerstones of the business.