Probabilistic model indicates PV module warranty reliability

U.S.-Spanish researchers have proposed a new way to assess the reliability of PV modules and their warranties. It is impossible to fulfill a 25-year warranty if the threshold of returned modules exceeds 5% and the annual degradation rate is over 0.73%.

Chinese PV Industry Brief: 1 GW of distributed solar came online in August

More than 1 GW of subsidized small solar arrays were installed in China last month alone and manufacturer Suntech has announced the start of operations at its 500 MW Indonesian cell and module fab.

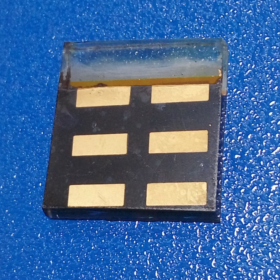

New molecular precursor for kesterite solar cells

Scientists in India have developed a new molecular precursor for applications in kesterite solar cells. They used the precursor to build a superstrate type solar cell with an efficiency that is purportedly among the highest ever recorded. They relied on a low-temperature process to manufacture the device.

Solaria brings its patent claims against Canadian Solar to ITC, adding a third patent

Californian solar module manufacturer Solaria Corporation has asked the U.S. International Trade Commission to issue an exclusion order to prevent the sale in the United States of Canadian Solar shingled solar modules it claims infringe its patents.

Indian solar leaders call for overhaul to navigate Covid-19

Indian PV manufacturers have highlighted the need to find alternative supply chains and to push automation and Internet of Things applications on the factory floor, in order to keep production running amid raw material and labor shortages.

Thin-film agrivoltaic solar tubes

German tech company Tube Solar AG has secured €10.8 million to develop its cylindrical agrivoltaic modules. The lightweight devices could also be used on roofs until now considered unsuitable for PV.

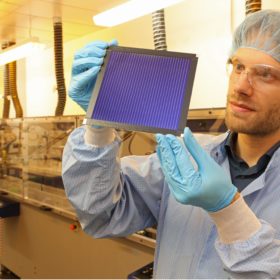

New world record for large-area organic PV module efficiency

Scientists in Germany have achieved 12.6% efficiency with a 26 sq cm organic panel and 11.7% for a 204 sq cm device. The feats were achieved with a new module layout and a slower, high-resolution, short-pulse laser structuring process.

Xinte Energy warns of possible polysilicon and inverter glut

The poly manufacturer discussed the impact of Covid-19 on its solar and wind project development business and fleshed out details of global polysilicon oversupply during a pandemic-hit first half of the year.

Polish solar manufacturers unite to compete with imports

Businesses, supported by the government, will join forces to strengthen their industry and contribute to the European Green Deal through made-in-EU products.

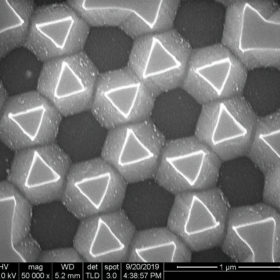

Nanostructures for ultrathin flexible wafer

Scientists in South Korea combined two processes to etch a nanostructure of tiny pyramids onto the surface of a silicon wafer. As well as trapping more light and increasing the cell efficiency, the group claims that its nanostructure improves the mechanical flexibility of the cells. This could potentially allow for the use of much thinner silicon wafers than is currently possible in production.