New protocols identify solar cell failures during production

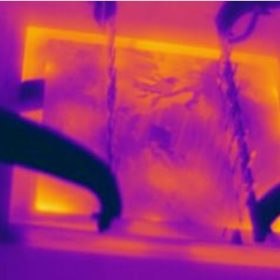

Two new pass/fail protocols are said to be able to separate cells which present high hot-spot possibility, show high current leakage and demonstrate intermediate behavior. The sorting technique relies on a manual solar simulator, an infrared camera and a tool to measure isolation.

India’s ReNew Power to build 2 GW factory

The Haryana-based developer will invest up to $266.9 million to set up a new solar cell and module manufacturing facility.

Chinese PV Industry Brief: TCL acquires Zhonghuan, distributed-generation PV soars

TCL, one of China’s biggest electronics manufacturers, has acquired Zhonghuan Semiconductor. The National Energy Administration, meanwhile, reported record growth for the distributed-generation PV segment in June.

URE announces Taiwan factory disposal

The Taiwanese manufacturer said it has sold its Jhunan Kebei plant to a Taiwan-based maker of masks for semiconductor production. However, it will increase capacity at its manufacturing facility in Tainan by up to 200 MW in the third quarter.

How the cracks are forming

Scientists in the United Kingdom have investigated the formation of cracks in PV cells, confirming that the high temperatures cells are exposed to during soldering for interconnection are a leading cause of cracking. Their findings will aid future research into module reliability and predictions of how cracks are likely to form.

Consolidation in the French solar module industry

Two module manufacturers, Systovi and Voltec Solar, plan to join forces to create a bigger player in the French solar manufacturing space.

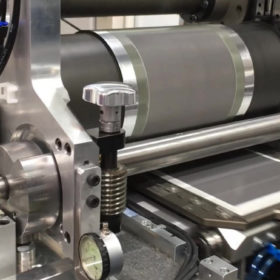

New equipment for solar cell metallization

The system can metallize the front and back sides of silicon solar cells with unprecedented precision and speed, Fraunhofer ISE said. The technology is also suitable for components such as printed circuit boards or chip cards.

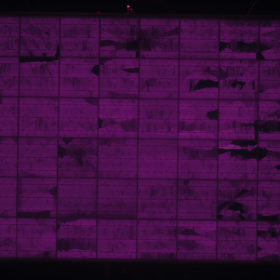

Foil method for PID test misleading if only one side of bifacial module is stressed

Results from PID stress tests can be misleading when bifacial PV modules are PID-stressed from just one side using the foil method in IEC TS 62804, according to a new study by Belgian researchers. An unintended electric field arises between the non-stressed side of the cell and the grounded interior of the climate chamber, which may have the undesired effect of causing additional PID stress.

CPV-solar thermal system delivering LCOE of $0.03/kWh

Researchers have created a device to produce electricity and steam at the same time. The system is said to offer 85.1% efficiency and deliver steam at up to 248 degrees Celsius. The converter combines III–V, triple-junction solar cells and a high-efficiency solar thermal system based on parabolic trough collectors.

Interview: Applying circular solutions to solar waste manufacturing and end-of-life modules

EVA films are a key barrier to solar module recycling because of the glues involved in their use. An EU-funded research project is aiming to address the issue, among others, with a circular manufacturing approach. pv magazine spoke to two of the professionals involved in the EU-backed Cabriss project.