Now or never for the EU

The European solar industry is on its knees, but the EU appears willing to set a course for reconstruction. With SolarPower Europe and the European Solar Manufacturing Council, there are now two associations that are actively advancing a course for strong solar industrial policy among the EU bureaucrats in Brussels. The goals, however, are somewhat different.

The outlook is sunny for solar in 2019, according to Credit Suisse

Although the investment bank says large manufacturers will suffer from continuing panel price falls, developers will be able to take advantage and experts predict a resurgence in the global market next year.

2019 PV installations to hit 123 GW, global balance shifting, says IHS Markit

More predictions from IHS Markit reveal that 123 GW of solar PV installations are expected in 2019 – up 18% on the capacity additions expected this year. It also sees a market shift away from China, with two thirds of capacity located elsewhere. The overcapacity situation is also expected to ease.

Daqo relentlessly increases polysilicon output

Chinese polysilicon maker Daqo New Energy today announced it has raised its production capacity to 30,000 MT, with a further 5,000 to follow within six months, and 35,000 on top of that by the end of March 2020.

Wacker Chemie reaches agreement with Yingli over poly supply deals

If the German polysilicon manufacturer is the ‘Supplier A’ referred to in the Chinese panel maker’s annual report, Wacker has negotiated a near $33 million settlement from arbitration. As part of the settlement, Wacker will continue to supply its counterpart with poly up to 2028.

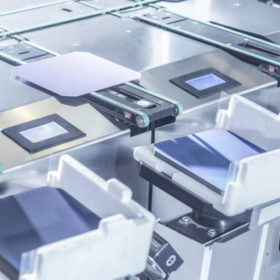

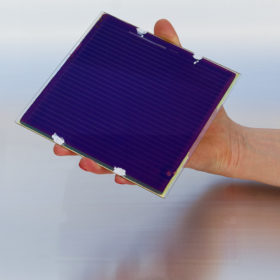

The weekend read: TOPCon boosts demand for EU equipment

Photovoltaic manufacturers in Asia are importing deposition reactors from the EU to test the latest word in silicon solar cell passivation. Two thin buffer layers sandwiched between silicon wafers and metal contacts are increasing the efficiency of conventional solar cells and setting new records. Equipment suppliers expect the technology to spread through the industry and boost their bottom line.

Meyer Burger picks up 600 MW heterojunction equipment order

Swiss equipment supplier Meyer Burger has received a CHF 74 million (US$74.4 million) order for a 600 MW production line combining heterojunction and smart wire technologies. The order was placed by an unnamed manufacturer, with the line expected to begin cell and module production in the second half of 2019.

First Solar sees a doubling coming in 2019

The thin film PV maker projects 5.4 to 5.6 GW of module shipments next year, more than double its current projected 2018 volumes of 2.6 to 2.7 GW.

German equipment suppliers report ‘strong’ bookings for cell, thin film segments

In its Q3 2018 report, VDMA finds that German PV equipment providers are continuing to enjoy much improved fortunes compared to the previous year. Solar cell and thin film equipment suppliers account for the vast majority of bookings.

Greatcell Solar enters administration

Australia-based perovskite solar cell specialist Greatcell Solar has failed to secure refinancing for its activities and has been forced to appoint administrators. The company lays the blame at the federal government’s door, pointing to the R&D rebate changes and policy settings that are unsupportive of renewable energy investment as the reasons behind its downfall.