Hyundai creates platform to help homeowners buy solar panels, battery and EV charger

The one-stop marketplace platform will be launched in the US market next year. It will help homeowners find the best combination of products depending on their consumption profile.

Solitek unveils 12.6%-efficient solar panel for greenhouses

The frameless solar panel has a light transmittance of 40% and nominal power of 235 W. The manufacturer offers a 30-year performance guarantee.

Chinese PV Industry Brief: JA Solar plans new 5 GW module factory, GCL-poly secures another big polysilicon order

Furthermore, China’s National Energy Administration (NEA) said residential PV installations totaling 1.93 GW were deployed in October alone and Heterojunction (HJT) solar new entrant Golden Solar became strategic partner of Gold Stone Energy Co Ltd.

BIPV modules from Estonia

Estonian start-up Roofit.solar recently raised €6.4 million from a group of investors led by Germany’s Baywa r.e. The company will use the funds to commercialize its three BIPV modules with power outputs of 110 to 160 W. All products rely on a 0.5 mm metal back sheet with highly durable pural coating.

Roundtables USA: Solar resiliency in an age of extremes – video now available

Industry leaders, policymakers, and stakeholders joined pv magazine senior editors in an insight-packed live event to discuss optimizing solar PV and accelerating deployment across the U.S. and the globe.

Talesun: Focus on solar tech and product innovation to survive

Several black swans have been circling over this year’s solar PV industry: rising raw material and product prices; supply chain issues and international logistics holdups; and power shortages in China, to name but the most disruptive. How is it possible for solar companies to survive under these conditions? According to Dong Shuguang, a PV veteran and President of Talesun Solar, they must focus on solar technologies like PERC, TOPCon and HJT, and product innovations that provide customer value.

Solar module factory with 1.2 GW capacity inaugurated in Saudi Arabia

The production equipment for the factory was provided by Spain’s Mondragon Assembly. The facility is currently the largest module factory in the Middle East.

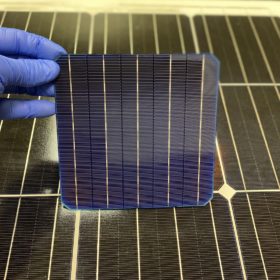

Shingled solar modules and shading

Scientists at Germany’s Fraunhofer Insititute for Solar Energy Systems (ISE) evaluated the performance of its newly introduced ‘Matrix’ approach to interconnecting shingled solar cells. The institute finds that, thanks to optimized current flows, energy yield of the Matrix approach could almost double that of standard shingled cell interconnection under random shading conditions.

Canadian Solar prepares to rein in production capacity expansion plans

While the Sino-Canadian business expects high polysilicon and shipping costs to be a temporary problem, CEO Shawn Qu has acknowledged the company will have overcapacity in cell and wafer production lines by the end of the year.

Novel solar cell architecture to reduce silver costs, improve voltage

Developed by a U.S.-based start-up, the new manufacturing process is claimed to reduce silver consumption and improve solar module performance by up to 3 W. It consists of connecting sub-cells in series within a single cell in order to increase the device voltage and without requiring cells to be physically broken and rewired.