Weathered PV backsheets have 46% faster flame spread than unweathered counterparts

Researchers in Singapore have accelerated the weathering of PV backsheets and investigated their flame spread behavior at different intervals. After 6 weeks, they found that weathered PV backsheets show 46% faster flame spread than unwearthered ones. They have also highlighted that current safety standards fail to account for long-term degradation.

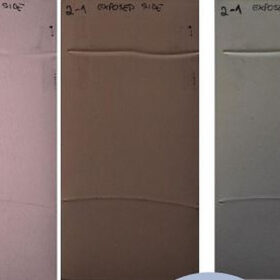

Field survey protocol for monitoring PV backsheet degradation

A research group including scientists from U.S. National Institute of Standards and Technology (NIST), Underwriter’s Laboratories Inc., and the National Renewable Energy Laboratory (NREL) has outlined a new protocol for assessing PV module backsheet degradation in the field. Through the proposed framework, the researchers analyzed PV backsheet degradation across 41 sites, with exposure times ranging from 1 to 38 years.

A closer look at backsheet degradation in desert enviromnents

A Qatari research group has analyzed the performance of polyethylene terephthalate backsheets in real outdoor testing conditions in desert areas and has identified the main causes that lead to degradation. These include prolonged exposure to high ultraviolet radiation, high operating temperature cycling, and relative humidity.

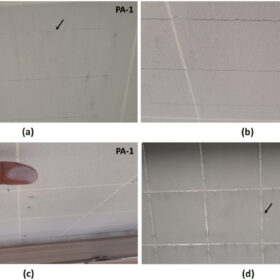

Reintroducing co-extruded backsheets in PV industry? Not a lost battle

Researchers in Austria have analyzed the crack propensity of backsheets made of polypropylene (PP) and have concluded these may be potentially used in solar module manufacturing, unlike co-extruded polyamide backsheets, which caused many headaches to the PV industry in the past. Furthermore, PP backsheets are claimed to have lower stiffness and higher flexibility than their laminated counterparts.

In search of the perfect polymer for PV backsheets, encapsulants

Scientists in Austria have examined the impact of different backsheet and encapsulant material combinations on module performance and degradation. This led them to develop a model to quantify the degradation rates of different materials, potentially helping manufacturers to identify better, longer-lasting materials for these vital module components.

Schüco warns of more solar modules with defective backsheets

Schüco has expanded its recent warning letter about potential solar panel defects to include more products. The new list includes PV modules the company delivered between 2010 and 2014.

Putting bifacial modules to the test

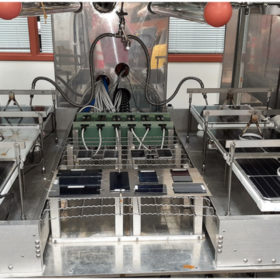

US scientists recently put different bifacial solar cells and modules through a series of tests at elevated temperature, humidity, voltage and mechanical stress levels. The tests revealed a range of light-induced and potential-induced degradation mechanisms that modules will likely suffer in the field.

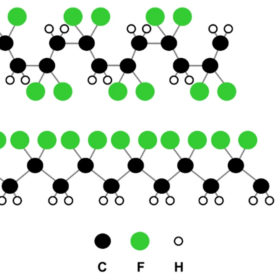

Putting polyvinylidene-fluoride backsheets to the test

US scientists tested PV modules built with backsheets and polyvinylidene-fluoride (PVDF) layers, to replicate the degradation the material has suffered in the field of accelerated testing. By exposing the modules to multiple stresses, they were able to cause degradation in the backsheet materials. Though this did not closely match what has been seen in the field, such testing can be useful in identifying potential weaknesses.

Flowable silicone sealant to repair damaged solar module backsheets

The special sealant is based on a product developed by U.S.-based Dow Corning for solar panel frame sealing. Its creators claim the new solution is able to make damaged panels recover high insulation resistance and operate normally.

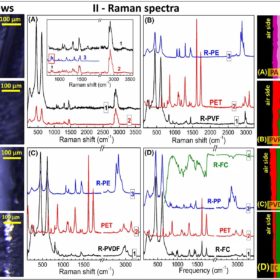

Monitoring near-infrared transmission for a healthy backsheet

Scientists in Germany developed a method to determine the structure and degradation of module backsheets and encapsulants in the field, by analyzing the material’s near infrared light transmission. Applying the theory to a multi-MW PV plant, the group was able to identify four different backsheet types. With further development, the method could be a valuable tool to monitor module degradation in the field and spot faults early on.