Dutch consortium seeks to reduce costs of hole transport layers for perovskite solar cells

Two Dutch manufacturers have teamed with TNO’s perovskite solar cell experts to integrate spatial atomic layer deposition equipment to produce ultra-thin, high-quality nickel-oxide hole transport layers in a roll-to-roll process. The team targeting production integration in mid-2027, with full-scale production by 2030.

Replacing silver in PV manufacturing with new graphene electrode technology

Swiss-British university spinoff, GraphEnergyTech, is developing graphene electrode technology to replace silver and other metals traditionally used in solar cell manufacturing.

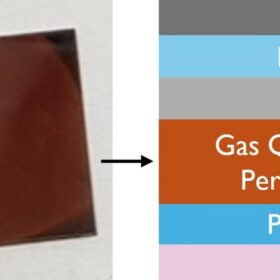

Gas quenching with helium, argon for more stable perovskite solar cells

Kuwait University researchers investigated the relationship between the molecular weight of the quenching gas and the morphology of perovskite films used in solar cells, finding that argon and helium extended device lifetimes compared to using the more conventional nitrogen.

Chinese scientists build 20.3%-efficient mini inverted perovskite solar modules via slot die coating

A team led by University of Electronic Science and Technology of China (UESTC) has found that pyrrodiazole as an additive in formamidinium iodide (FAI)-based inverted perovskite solar enables larger area devices made with industry-compatible slot die coating. Modules made using the technology achieved 20.3% certified power conversion efficiency and retained 94% of initial efficiency after 1,000 h in standard testing.

Power Roll developing 12.8%-efficient back-contact perovskite solar devices

Researchers from the U.K.’s University of Sheffield and Power Roll, a perovskite solar PV technology company, have achieved 12.8% power conversion efficiency in indium-free devices based on novel back-contact process. A slot-die coating process was demonstrated, compatible with roll-to-roll manufacturing.

Strategies to reduce perovskite solar cell degradation caused by thermal stress

An international team investigated repeated thermal stress on metal-halide perovskite solar cells and has proposed strategies to boost resistance to degradation effects of diurnal cycles or geographical conditions.

Water-based recycling of perovskite solar cells

An international team has developed a new technique to recycle perovskite solar cells (PSC) made on glass substrates using a water-based solution. Tests showed that the recycled cells were as efficient and stable as the original devices.

Microquanta developing perovskite solar modules for BIPV applications

The Chinese perovskite solar cell and module maker said its custom-designed double-glass perovskite modules measure 1,200 mm x 1,000 mm and achieve a light transmittance of around 40%.

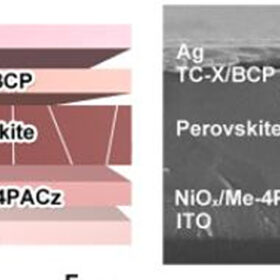

Inverted perovskite solar cell based on stabilized C60 achieves 25.6% efficiency

An international team has utilized an n-type polymeric additive to stabilize C60 molecules for use in inverted perovskite PV cells. Thanks to this approach, the researchers built a solar cell with the highest efficiency value ever recorded for perovskite devices based on solution processed C60 electron transport layers.

Chinese PV Industry Brief: UtmoLight starts perosvkite module production

UtmoLight says it has launched the world’s first gigawatt-scale perovskite solar module production line at a facility in Wuxi, China. The plant will annually produce 1.8 million panels, with a target of achieving 20% efficiency in mass production by 2025.