Millions saved with onsite mulching of solar trash

Florida utility FPL has been mulching solar panel packaging – cardboard boxes and pallets – to save approximately $130,000 per 75 MW (AC) site, compared to standard disposal practices.

Australia prepares for first solar ‘upcycling’ facility while recycling operations expand

As Australia stares down a deluge of worn out solar panels, recycling – and indeed upcycling – programs are grinding into gear. In Victoria, a site has been found for Australia’s first facility to recover and reuse solar module materials, while Reclaim PV has extended its manufacturer partner and pickup location lists.

Solar module disassembly equipment from Japan

Developed by Japanese PV equipment provider NPC Incorporated, the solar module disassembly line is claimed to enable the reuse of frames, junction boxes, intact broken glass, solar cells and EVA sheets.

Australian solar module manufacturer commits to recycling strategy

Reclaim PV has added another partner to its national solar panel recycling and recovery program with South Australian-based manufacturer Tindo Solar committing to a program that will see close to 100% of the solar PV panels that it handles recycled and re-used in the industry.

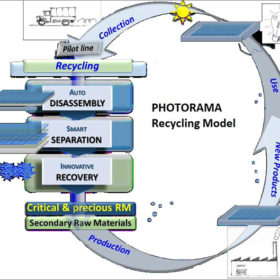

European consortium develops pilot line for complete PV module recycling

A European consortium consisting of Italian energy agency Enea and the French Alternative Energies and Atomic Energy Commission, among other entities, has developed a plan to build a low-emissions pilot line to recover critical and precious metals such as silicon, indium, gallium and silver. The line will be designed to reintroduce new materials and new products into the production cycle.

Reuse or replace? IEA PVPS analysis considers all options for underperfoming PV modules

In a new report, experts from the International Energy Agency Photovoltaic Power System Programme (IEA-PVPS) have assessed the economical and environmental benefits of repairing and reusing or replacing solar modules that are not complying with a 30-year expected lifetime. They found that reusing offers the best environmental impact in all cases, while the profitability of this option is currently guaranteed only by rooftop PV under certain conditions. As for large-scale solar, module replacement remains the most competitive option.

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

Circular economy could support India’s push for clean energy, self-reliance

The recovery of valuable raw materials from end-of-life solar panels and batteries presents a great opportunity for India to secure future supplies as the nation chases its ambitious renewable energy targets.

Recycling solar panels: Making the numbers work

NREL researchers said a profitable and sustainable solar panel recycling industry could establish itself by 2032. Here’s how the numbers work.

NREL model shows current incentives for PV module recycling are insufficient

Analysts at the US research institite modeled PV recycling strategies and found that current incentives are not well-aligned to drive recycling.