From pv magazine USA

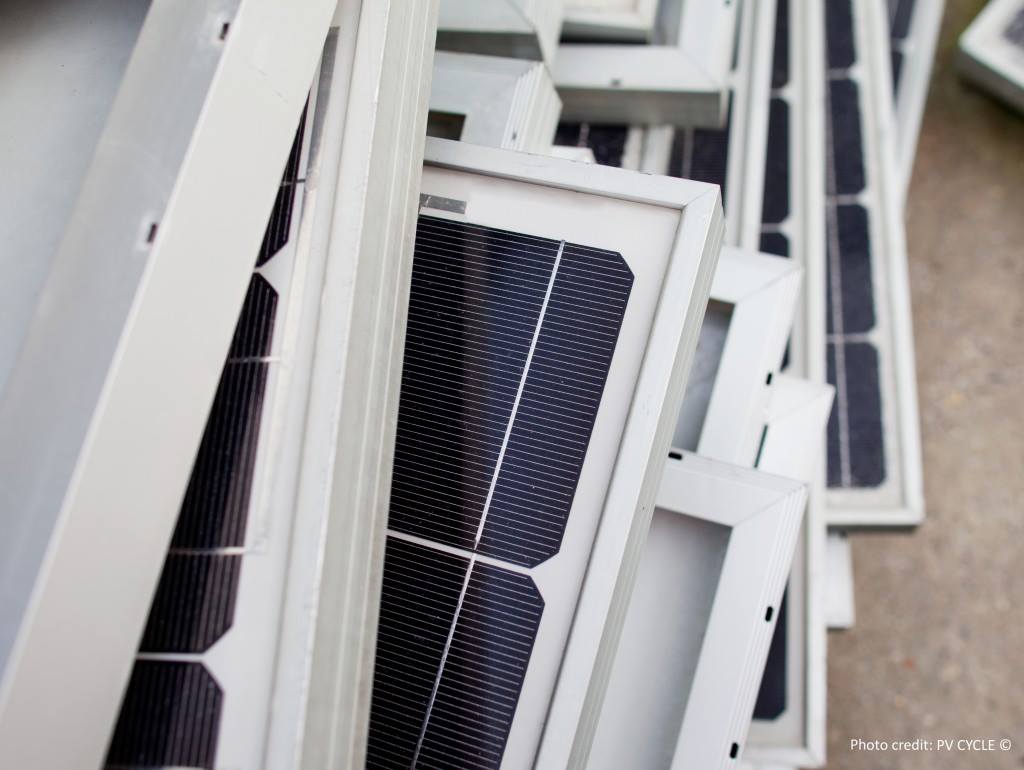

Solar panel waste may reach the weight of 30 Empire State Buildings, or 10 million metric tons, by 2050, said the National Renewable Energy Laboratory (NREL).

As a result, interest is growing in minimizing and maximizing the value of PV materials through the creation of a circular economy for energy materials.

NREL said most research thus far has been directed toward developing methods to technically and economically reuse solar materials, but does not consider how social behaviors fit into the picture. Analysts said the consideration of consumer behavior and awareness can allow consumers to become part of the solution, and can accelerate the adoption of circular economy approaches.

(Read “Partners turn to blockchain to expand solar module recycling.”)

The analysts applied agent-based modeling, which represents customer groups as “agents,” or independent decision-making entities that are trained based on data to simulate decisions made on behalf of the groups they represent.

Four agents were modeled: PV owners, installers, recyclers, and manufacturers. Agents selected from the options of repair, reuse, recycle, landfill, or store an aging PV module under different scenarios, like varying recycling policies or costs.

The model used agent decisions to calculate PV mass avoided, as well as the economic impact like costs for manufacturers or net revenue for recyclers and installers. It also factored in the learning effect for recycling, a decrease in costs due to scale and technology advancement.

Incentives

The model found that in today’s conditions, few incentives exist to encourage recycling. Based on a projection of 500 GW installed in the U.S. by 2050, 9.1 million metric tons of waste would be produced. The analysts modeled a current average recycling cost of $28 per module, repairs at $65 per module, and landfills at only $1.38 per module. Used modules could be sold at 36% of new module prices.

Popular content

Based on those figures, the model estimated that over the next 30 years, 80% of modules will be landfilled, 1% reused, and 10% recycled.

At today’s material recovery rate, the total recycled mass would be around 8%. The analysts said with today’s technology, PV modules aren’t easy to separate, and mostly low-value materials are extracted. As a result, there isn’t enough revenue to incentivize more recycling.

How to boost recycling

The NREL model showed that a reduced recycling cost would add a significant boost in adoption. Lowering the cost per module from $28 to $18, for example, could potentially lead to an increase in the recycling rate by more than one-third by 2050.

The study also said that social influence can have an impact on recycling. For example, early adopters who have a generally positive outlook on the practice can pave the way. This can cause a virtuous cycle, where consumers not only can influence those around them, but also drive down recycling costs by helping the recycling industry to grow.

Higher material recovery rates also would drive adoption. New processes that recover high value materials like silver, copper, and silicon for reuse could create a recycler cumulative net income of $1.3 billion by 2050, said NREL.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

As long as the financial world will ask for a return of 30% in less of 3 years when it need at least one year to build one unit dealing with a real recovery of the materials, it will be impossible for the companies having the technology to finance by their own the investment. In practice, lowering the treatment costs will lead to what we see: export of wastes under the name of “second hand” panels …