Improving LECO-compatible silver pastes to ensure TOPCon reliabilty

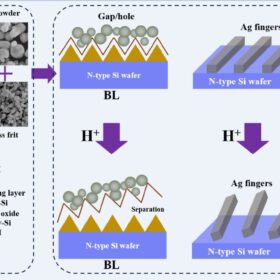

Researchers in China have created new silver pastes for TOPCon solar cell LECO manufacturing. The new pastes integrate either aluminum, gallium or iron and can reportedly keep cells’ electrodes securely anchored to the silicon cell surface due to the enhanced stability of the lead oxide (PbO) component in the glass powder.

Reducing TOPCon solar cell degradation via copper plating

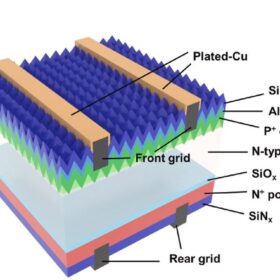

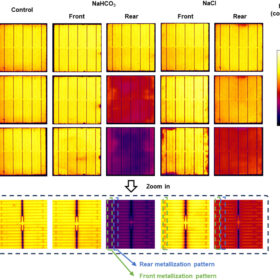

Researchers at the University of New South Wales have used a 1 µm copper plating layer on the front silver grid of a TOPCon solar cell to create a protective barrier that reportedly reduces corrosion susceptibility. The cell showed significantly lower contaminant-induced degradation that unprotected reference devices.

New research shows vulnerability of TOPCon solar cells to contact corrosion

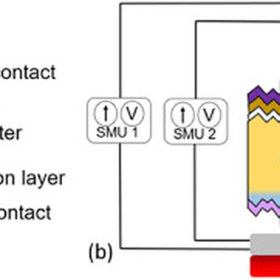

Researchers at the University of New South Wales claim to have identified new TOPCon contact degradation mechanisms that are significantly influenced by the combination of ions and aluminum-silver paste compositions. The primary degradation mechanism was a significant increase in series resistance.

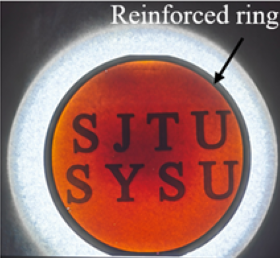

Chinese researchers develop 28-µm silicon solar cell with 20% efficiency, 0% breakage rate

A research team in China has developed a novel thin-silicon wafer reinforced ring (TSRR) to protect ultra-thin wafers and solar cells during production. This technique consists of applying the ring at the edge of thin wafers and is compatible with all silicon solar module technology.

Fraunhofer ISE unveils M10 TOPCon solar cell with 24.0% efficiency

The German research institute said the new 120 µm thin solar cell could exceed 25% efficiency with the next optimization steps. The device was metalized via screen-printed contact fingers and calibrated by scientists at the Institute for Solar Energy Research Hamelin.

Maxeon sues REC, Hanwha Qcells for alleged TOPCon patent infringement

Maxeon has filed two different lawsuits in the United States against Hanwha Qcells and REC over claims that the two manufacturers used an unspecified tunnel oxide passivated contact (TOPCon) solar cell technology.

Solarspace opens TOPcon solar cell factory in China

China’s Solarspace has inaugurated the first stage of a 16 GW n-type TOPCon solar cell manufacturing facility. The facility will also start producing high-efficiency TOPCon solar modules at the beginning of 2023.

Assessment of hydrogen-induced contact resistance in TOPCon solar cells

Researchers have looked at how hydrogen-induced contact resistance could help to reduce changes in series resistance, in either TOPCon or PERC solar cells. They said degradation occurs purely at the n-type silicon-to-silver (Ag) contact on both cell architectures.

TOPCon vs PERC

TOPCon solar cells are on their way to fully compete with PERC solar products, according to recent research from Germany’s Fraunhofer ISE. Efficiency gains for the TOPCon concept, however, are necessary to help it capture more market share, as production costs remain higher than those for PERC tech. A series of cost-driven strategies to make TOPCon modules advance were outlined in the study.

Longi sets TOPCon cell record of 25.09%

The world’s number one solar manufacturer said the result has been confirmed by the Institute for Solar Energy Research in Hamelin, Germany.