When is fake news not fake news? The answer: when it’s published on April 1. Then it’s fair game. Sort of. In annual pv magazine tradition, we marked this year’s April Fool’s Day in typical fashion with a lighthearted take on Brexit. If you managed to immediately spot that this was a spoof story – well done!

On to more serious matters, and it is Turkey that has once again taken the spotlight this week. Following on from the recent 1 GW tender in Konya, the Turkish PV sector has continued to grab the headlines, not least with the news that the Turkish government has this week concluded a month-long investigation into price dumping in the country.

Its conclusion was to list some China-based module manufacturers that are now going to be subject to an anti-dumping fee of $20/square meter. The list of firms includes:

Hanwha Q Cells (Qidong)

Zhejiang Jinko Solar

Chint Solar (Zhejiang)

ByD (Shangluo) Industrial

Canadian Solar (Changshu)

Canadian Solar (Luoyang)

CEEG (Shanghai) Solar Science Technology

CEEG Nanjing Renewable Energy

Changzhou Trina Solar Energy

Trina Solar (Changzou) Science and Technology

Hainan Yingli New Energy Resources

Yingi Energy (China)

Hefei Chinaland Solar Energy

Jianhsu Seraphim Solar System

Perlight Solar

Renesolar Jiangsu

Furthermore, all other PV panel manufacturers who have set up manufacturing plants in China, and did not respond to the investigation are subject to an antidumping fee of $25/m².

Ates Ugurel, founder of Turkey’s Solar Energy Society Solarbaba, told pv magazine that “the imposed antidumping fee will increase the PV panel’s cost by approximately 30 to 35%. The current average PV panel price is around $0.35/W, and it will now rise to $0.45 to $0.48/W.”

Elsewhere in Turkey

Another significant piece of news to come out of Turkey this week was the 50% acquisition by Çalik Group of Turkish EPC contractors Halk Enerji.

As revealed to pv magazine by the group’s general manager Yalçın Adıyaman, the two companies now plan to create a holding company, whose focus will be the development of renewable energy power plants.

Adiyaman said that Halk Enerji is expected to reach a turnover of $500 million in 2017. Adiyaman also added that Turkey-based Aktif Bank, which is itself part of the Çalik Group, is able to provide financing for projects of every size. The new company will rely on the group’s network across the world. Adiyaman stressed that the two companies are also considering entering the storage business, and other segments such as solar leasing.

Halk Enerji will focus on PV markets in Central Asia, the Balkans and the MENA region. In 2017, the company will be particularly active in Turkey, where the segment for unlicensed PV projects up to 1 MW is expected to see strong growth. Adiyaman believes that approximately 2 GW of these systems could be connected to the grid in Turkey this year. The main reason for this expected growth, Adiyaman explained, is the reduction of the grid-connection fee, which was reduced from $40,000 to between $5,000 and $10,000 at the beginning of 2017.

21.2% perovskite cell breakthrough

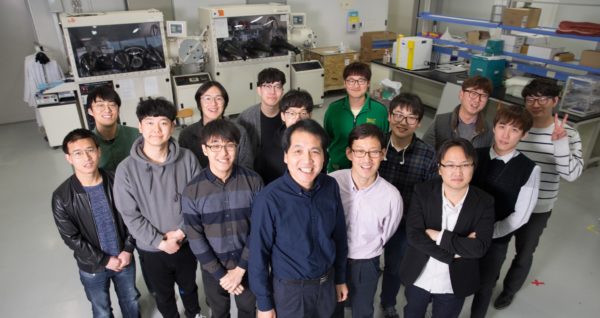

Researchers at the Ulsan Institute of Science and Technology (UNIST) in South Korea have announced the development of a method to produce perovskite solar cells, which the University could contribute to commercialization of the technology.

A study published in the March issue of academic journal Science demonstrates a process which has produced hybrid organic/inorganic perovskite solar cells of 21.2% efficiency, with good stability – retaining 93% of the initial performance after 1,000 hours of light exposure.

The University claim this represents a new world record for perovskite solar cells, in terms of both efficiency and stability.

The study, a collaboration between UNIST and the Korea Institute of Chemical Technology (KRICT), proposes a new manufacturing method for perovskites, which it calls the ‘hot-pressing method’. The University says that this method allows the production of stable, low cost-high efficiency perovskite solar cells.

Perovskites have been an area of high interest for the PV industry for several years now, as the material has the potential to be used in cheap and highly efficient solar cells. Research teams and companies all over the world are working to achieve commercialization of the technology.

Enel goes cell

Italian power provider Enel, which is active in the solar and renewable energy sectors through its unit Enel Green Power (EGP), is coordinating a research project aimed at setting up solar cell production at the company’s manufacturing facility in Catania on the Italian island of Sicily.

The project, named Automated photovoltaic cell and Module industrial Production to regain and secure European Renewable Energy market (AMPERE), is being funded by the EU with €14 million ($14.9 million). The project’s partners are the Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA), the local research institute for microelectronics and microsystems CNR-IMM, and Italy-based Rise Technology, a start-up company in the interconnection and packaging for the microelectronics industry. Further international partners are Germany’s Fraunhofer ISE, French Solar Energy Research Center (CEA-INES) and Meyer Burger Research AG among others.

The pilot production, ENEA said in a press release, will manufacture heterojunction solar cells based on crystalline and amorphous silicon. Final goal of the project is a PV module production that can ensure an efficiency of around 23% with production costs above €0.42 per W and an annual degradation rate of less than 0.5%. The consortium aims at bringing the production capacity of Enel’s factory in Catania up to 1 GW over the next five years.

ENEA’s Mario Tucci told pv magazine that: “Technical, cconomic and environmental sustainability of the 100 MWp production line will be demonstrated, in particular competitive generation costs, using high efficiency and/or intrinsic bi-faciality of the selected technologies. The latter in particular will ensure higher annual energy production, and hence significantly lower LCOE than conventional technologies. These expected outcomes will be assessed and evaluated as a solid milestone for the viability of a 250 MWp production scale factory in 2020, paving the way to the first GWp factory in 2022.”

Enel announced it will convert its 3Sun factory to the production of bi-facial, heterojunction modules in early March. At the time, the company said it expects to launch its new modules in 2018, and to reach a capacity of 240 MW in 2019.

Canceled auctions in Brazil

The Brazilian government has published a decree for the introduction of an auction system to cancel the PPAs awarded under the country’s reserve energy auctions. Under this new type of auction, developers awarded projects in the reserve energy auctions will bid for their projects to be cancelled, with winning bidders avoiding fines for non-completion and retaining their project guarantees. The auction is intended to cancel power projects selected in the reserve energy auctions which are not being implemented.

In recent years, Brazilian authorities have contracted several GWs of power from large-scale renewable energy and PV projects, which were never built, but could now participate in this new auction.

The Government has not yet established when the auction will be held, or the volume of projects that could participate. The country’s Ministry of Mines and Energy (MME) will manage the auction following the recommendations of government-run energy agency Empresa de Pesquisa Energética (EPE).

Under the scheme, developers submitting the highest bids will not have to pay the fine for failing to complete their projects and, at the same time, will not lose their project guarantees.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.