A research project three years in the making that examined the most viable ways to make solar PV inverters more cost-effective has this week been concluded by German institute Fraunhofer ISE.

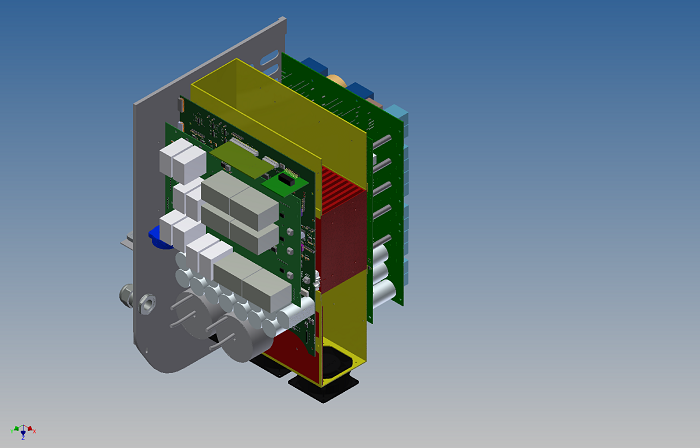

The chief conclusion of the PV-Pack project – conducted by a consortium of SMA Solar Technology, Fraunhofer Institute for Manufacturing and Applied Materials Research IFAM, Phoenix Contact and Fraunhofer ISE – was that to lower costs without impacting power output or performance, inverters built with more highly integrated components were more effective.

The expert parties involved in the project began in 2014 by analyzing the costs of mechanical and electromechanical components in a typical PV inverter in the 10 to 40 kW power range. What they found was that these components comprised 70% of a typical inverter’s overall cost.

“One way of cutting costs is to optimize the technologies of the components used in lower power classes in such a way that devices with more power can be developed,” said Fraunhofer ISE’s head of the circuit development and hardware design team in the power electronics and grid technologies department, Sebastian Franz.

The components include, on the mechanical side, housing, support structures and cooling components, and on the electromechanical side, plug connectors, inductances and circuit boards.

The key aim was to find ways to optimize the cooling and packaging of the inverter – the surest route towards lower cost without compromising power or efficiency. In targeting the so-called “hot core” of the inverter, the researchers were able to achieve their aims: by uncoupling the cooling element from the housing, they could increase the maximum temperature by 30%, and by sintering materials drastically reduce the amount of material used.

Popular content

And by focusing on lowering the temperature of the inverter’s various temperature zones, the researchers could then fit cost-efficient components – that tend to have lower temperature requirements – into these new, cooler zones.

Additionally, by using silicon carbide semiconductors (SiC) the research team could increase power density and further reduce material size. SiC has increased switching frequency, and thus enables a reduction in the size of the passive elements in the inverter. As a result, efficiency came in at 98.8%, which is above the average European inverter efficiency of 98.3%. The resultant inverter was also 58.5 kg in weight, with a 1,200 W/kg ration and 110 liters of installation space.

“The power density greatly exceeds devices available on the market,” concluded Frank.

The PV-Pack project took three years and received €1.9 million in funding from Germany’s Federal Ministry of Education and Research.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.