Scientists from New York’s Rensselaer Polytechnic Institute say they have improved the stability of vanadium disulfide in lithium-ion battery cathodes for consumer electronics, solar storage and electric vehicles.

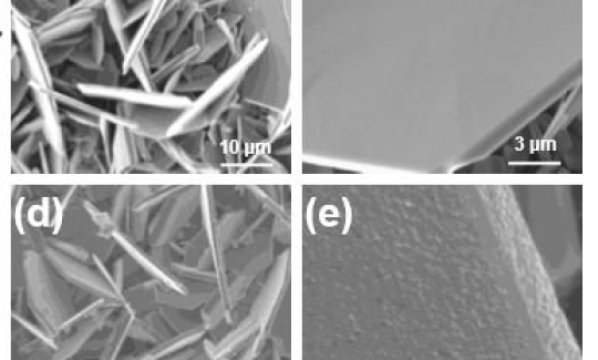

In the paper Vanadium disulfide flakes with nanolayered titanium disulfide coating as cathode materials in lithium-ion batteries, published in Nature, the scientists say they were able to render vanadium disulfide flakes in a lithium-ion battery more stable by conformally coating them with a titanium disulfide layer around 2.5 nm thick.

They said the titanium disulfide (TiS2) coating was far less susceptible to ‘Peierls distortion’ during the lithiation-delithiation process, enabling it to stabilize the underlying vanadium disulfide. Peierls distortion affects the periodic lattice of a one-dimensional crystal, resulting in lower thermal conductivity.

Fighting Peierls distortion

Popular content

The researchers said they observed how instability of the vanadium disulfide used in lithium-ion batteries occurred. The paper states lithium insertion is responsible for the Peierls distortion – defined as an asymmetry in the spacing between vanadium atoms – and causes the breakup of vanadium disulfide flakes.

“The TiS2 coating acts as a buffer layer,” stated the paper. “It holds the VS2 [vanadium sulfide] material together, providing mechanical support. The TiS2 crystal remains relatively undisturbed during the lithium migration process, which explains why the TiS2 coating dramatically improves the lifetime of the VS2 cathode. As a result, the outer TiS2 is resilient to the charging/discharging cycles while the inner VS2 layers are more protected from degradation due to the mechanical support provided by the TiS2 coating.”

Electrochemical testing, in situ optical imaging and first principles density functional theory calculations were used to verify the stability of the flakes was significantly improved. “These findings provide new opportunity for the rational design of conductive TMD [transition metal dichalcogenide] materials for building high-performance li-ion batteries,” added the paper.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.