A group of international researchers led by the University of Rome Tor Vergata in Italy claims to have developed an 18.3%-efficient methylammonium-free perovskite solar cell through deposition processed in air.

“Thanks to this deposition technique we are able to deposit large area substrates up to A4 size (20x30cm) without using lab scaling technique for perovskite deposition, also avoiding any kind of antisolvent waste,” Luigi Angelo Castriotta, a researcher at the university's Centre for Hybrid and Organic Solar Energy (CHOSE), told pv magazine.

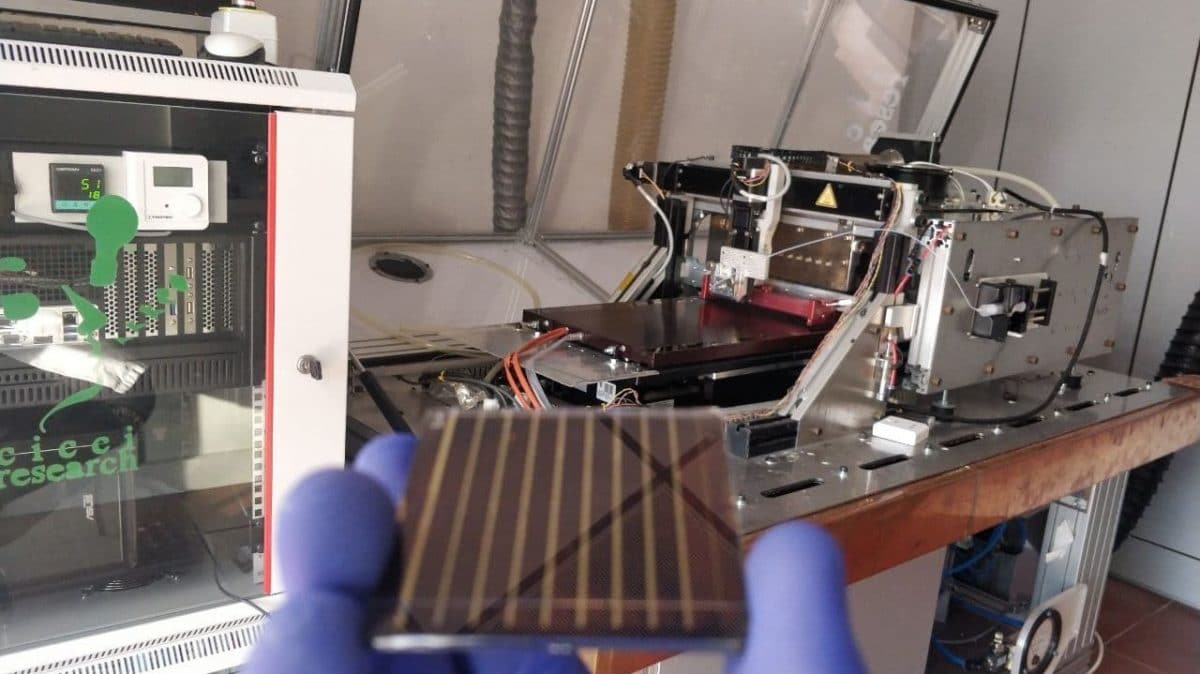

The use of this upscalable technique, which is based on an automatized blade-slot die coater designed by Cicci Research, a CHOSE a spin-off, helps save around 30% of solvents during the perovskite deposition, Castriotta explained. “Solvents usage represent 17% of the total cost of a perovskite device. By using this technique we can reduce this amount up to 6%, providing also an environmental friendly approach.”

A double-cation cesium formamidinium (CsFA) perovskite was air processed by applying potassium doped graphene oxide on top of the mesoporous layer and infrared annealing of the perovskite. “The fabricated devices showed an improved stability test compared to a standard multi-cation perovskite fabricated in an inert atmosphere,” the research team stated.

In the deposition process, potassium-doped graphene oxide (GO-K) was used as an interlayer, between the mesoporous titanium oxide (TiO2) and the perovskite. Infrared annealing (IRA) was utilized to limit charge losses at the perovskite/TiO2 interface.” The fine-tuning of GO-K and infrared annealing have a strong impact on the cell and modules’ performance in terms of efficiency and stability,” the research group emphasized. “These results, obtained in ambient conditions, pave the way towards the industrialization of perovskite solar cell-based photovoltaic technology.”

GO-K is a grey-brown compound in powder form and dark grey in dispersion form, which can be well dispersed in polar solvents. “It is a low-cost material, as its precursor materials are graphite and potassium carbonate (K2CO3), and its dispersion remains stable for more than two months,” Castriotta explained.

Mina M. Styliniakis, a researcher at Greece's Mediterranean University Heraklion, which was also involved in the development of the cell, estimated the overall cost of the proposed synthetic process, taking into account all masses and volumes of the materials used, at around €0.025 per cell. “The preparation of 4 mL of a GO-K dispersion costs only €0.020,” Castriotta affirmed.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.