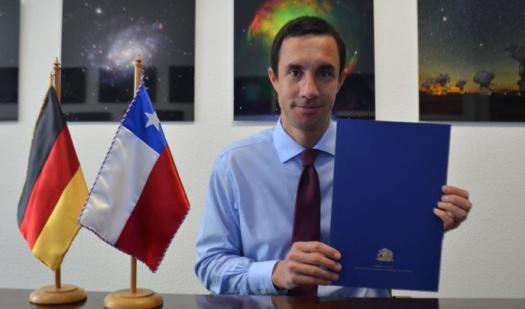

Chile’s Minister of Energy Juan Carlos Jobet and German Minister of Economy and Energy Peter Altmaier signed a joint declaration on Tuesday to strengthen cooperation on green hydrogen. As part of the collaboration, a green hydrogen working group will be created as part of the Chilean-German Energy Association (AEE) to identify viable green hydrogen projects, facilitate the development of supply chains abroad, share knowledge and experiences in terms of safety standards and procedures. The partnership also aims to advance the development of certification systems for low carbon emissions and promote the joint development of research, pilot and demonstration projects. Altmaier referred to the H2 Global program, a German government initiative that seeks to import green hydrogen and support electrolyzer projects abroad. He added that cooperation with Chile was important because Germany's major energy sector players were seeking new trade routes for imports of green hydrogen as a cleaner alternative to fossil fuels. Also on Tuesday, Chilean President Sebastián Piñera and German Chancellor Angela Merkel held a video conference. According to the Chilean government, one of the focuses was the development of clean energy sources and green hydrogen. In December, the German ministry announced its support for Highly Innovative Fuels (HIF), the first eFuels project to be developed in Chile, which consists of the generation and use of green hydrogen to produce methanol and gasoline. The German government will support the project with €8.2 million ($ 9.76 million) through Siemens Energy.

The Uruguayan Ministry of Industry, Energy and Mining (MIEM) said it has found significant interest from “important actors” in the energy sector and hydrogen in particular, paving the way for the next stage of its H2U initiative. Since 2018, an inter-institutional group has been analyzing how to develop green hydrogen in Uruguay. In this framework, pre-feasibility studies were conducted to carry out a pilot project for the production of green hydrogen to supply trucks and buses. “After the process was closed, efforts began to focus on processing and systematizing the information received in order to refine the drafting of the specifications of the call for proposals that we hope to be developing in the second half of 2021,” reads a note released on Tuesday. According to MIEM, the pilot project could be in heavy transport, production of green fertilizers, or production of green ammonia as fuel for ships.

Texas oil field services company Baker Hughes and engineering, procurement and construction company Samsung Engineering have announced a collaboration with regards to low to zero-carbon projects utilizing carbon capture, utilization and storage (CCUS) and hydrogen technologies. For now the focus is on key Korean customers with projects across refineries, petrochemical plants, water treatment and air pollution prevention applications. “We are positioning ourselves as a green solution provider, and we will continue to invest in technology and develop new projects for pursuing carbon neutrality,” Duckkyu Moon, senior vice president and head of Samsung Engineering's Solution Business Division, said in a statement Tuesday.

Norway-based consultancy DNV expects global demand for hydrogen as an energy carrier to grow from practically zero in 2019 to 24 exajoules (EJ) a year in 2050. “Uptake will mainly be in the manufacturing and transport sectors, adding to the continued non-energy uses of hydrogen such as fertilizer and feedstock,” reads a recent report. According to DNV, hydrogen from fossil fuels is likely to play an important role in establishing hydrogen as a significant energy carrier. DNV expects it will take at least another decade for green hydrogen to become competitive. “The paths of different hydrogen colours will be dependent on available resources, policies, carbon prices, and the risks investors take – and all of these parameters will vary regionally.” The consultancy sees green hydrogen (solar PV) production costs in Latin America and Africa already in the range of $2 to $3 per kilogram. “This will further encourage a global green hydrogen import/export market.” DNV also addressed the competition between electrolysis technologies, focusing on alkaline electrolysis (AE), solid oxide electrolysis (SOE), proton exchange membrane (PEM) and anion exchange membrane (AEM). “Costs are predicted to decrease by 50% solely on the basis of economies of scale. This should enable SOE to compete with AE and PEM by 2030,” reads the report, adding that “AEM still requires the most development.”

Scientists from the U.S. Department of Energy's Pacific Northwest National Laboratory (PNNL) have developed a novel valuation framework for hydrogen storage that they claim can help utilities, regulators, energy suppliers and researchers assess the economic benefits of storing the clean fuel. Called the Hydrogen Energy Storage Evaluation Tool (HESET), the new framework is an adapted version of PNNL's Energy Storage Evaluation Tool (ESET), which was created by the research group in 2013. It is able to assess individual system components, different hydrogen flow pathways, various grid and end-user services, and multi-dimensional couplings. “This tool is unique in that it allows for modeling of stacked revenue streams, like grid services and several different hydrogen end uses,” said PNNL researcher Di Wu. Stored hydrogen may be used for grid services such as frequency regulation, capacity value, deferral of transmission, distribution equipment upgrades, demand charge reductions, and demand response, he added.

Popular content

Bouygues Energies & Services and supply chain specialist FM Logistic have agreed to deploy a green hydrogen project powered by solar energy in the city of Orléans. Green hydrogen will be distributed via private and public stations deployed by Bouygues throughout the city. The H2HUB Loiret project aims to produce up to 800 kilograms a day of renewable hydrogen in the long term near an FM Logistic site. According to a company spokesperson, interviewed by pv magazine France, the energy to power the electrolysers will come from solar panels installed at the regional level, the location and quantity of which have not yet been announced. Solar panels on the roof of the Escrennes logistics platform, operated by FM Logistic for cosmetic companies such as Sephora, will provide additional power. The amount of energy needed and the capacity of the electrolyser will ultimately depend on the amount of hydrogen that local authorities and companies will be willing to buy, the spokesperson added.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

6 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.