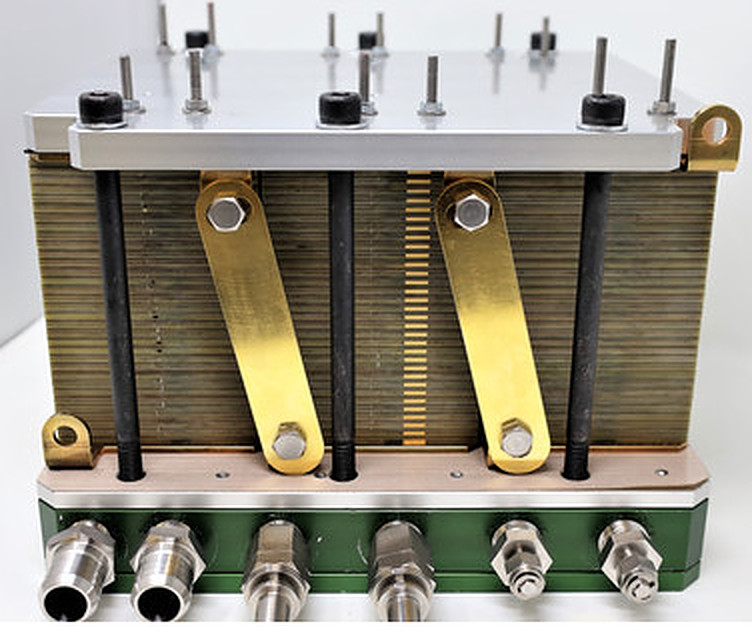

Sea-kit, a U.K.-based designer of marine, uncrewed surface vessels (USVs), has secured public funding to install a printed circuit board-based hydrogen fuel cell engineered by project partner Bramble Energy, on one of its vehicles. “Sea-Kit USVs have a dual diesel-electric hybrid drive, with propulsion coming from an electric motor powered by battery banks that are charged by in-situ diesel generators,” said Sea-Kit CEO Ben Simpson. “This project will replace one of the diesel generators with new hydrogen fuel cell technology from Bramble Energy, and demonstrate … offshore operation with zero carbon emissions.” Funding comes from the recent Clean Maritime Demonstration Competition by the U.K. Department for Transport and fellow state entity InnovateUK. The British government's Clean Maritime Plan aims to at least halve greenhouse gas emissions from shipping by 2050. “Data gathered from bench-testing and sea trials will be utilized for the design and build of similar USVs, as well as for larger uncrewed vessel builds in the near future,” read a statement about the funding award issued on Wednesday. West Sussex-based fuel cell developer Bramble Energy will design and manufacture a marine, customized version of its printed circuit board (PCB) fuel cell. “The use of PCBs, as opposed to metallic or graphite end plates, makes the technology more suited to rugged, marine environments,” added the press statement. InnovateUK and the companies involved claimed the use of a hydrogen fuel source on an USV would be a world first.

Italian electric utility Edison and energy transmission business Snam have signed a memorandum of understanding alongside Italian tech company Saipem and developer Alboran Hydrogen to work on the Puglia Green Hydrogen Valley project, a large scale initiative for the production and transport of green hydrogen in southern Italy. “The Puglia Green Hydrogen Valley project plans to build three green hydrogen production plants, in Brindisi, Taranto and Cerignola (Foggia), for a combined capacity of 220 MW and powered by [the] photovoltaic production of 380 MW in total,” said a press release about the project, published on Tuesday. “Once the three plants are operational, it is forecast that they will be able to produce about 300 million cubic meters of renewable hydrogen every year.” The project partners said their green hydrogen would be used primarily for local industry and would be blended into Snam's local gas network. The authorization process is already under way for the Brindisi project, which will involve PV project-powered electrolyzers with a capacity of 60 MW. “In order to execute the project, the partners anticipate creating a special purpose company ([with ownership divided thus:] Alboran 30%, Edison 30%, Snam 30%, [and] Saipem 10%) following the signing of binding agreements that still have to be negotiated by the parties.”

Indian multinational Tata Steel has announced it wants to adopt hydrogen for its steelworks in IJmuiden, in the Netherlands. In its attempt to reduce CO2 emissions, the company explored two options: carbon capture, usage and storage technology and hydrogen. “Today, Tata Steel has announced it will pursue the hydrogen route in IJmuiden, and undertake a detailed assessment in this regard,” the company announced on Wednesday. “This involves the introduction of direct reduced iron (DRI) technology, which can make iron using natural gas or hydrogen before it is converted to steel in one or more electric furnaces to be invested [in] in the future.” Tata said it will consult stakeholders to further develop the hydrogen option. “The decarbonization pathway in IJmuiden will also help us chart the future transition roadmap of Tata Steel’s other integrated steelmaking sites,” said TV Narendran, CEO and managing director of Tata Steel, and chairman of the supervisory board of Tata Steel Netherlands. Earlier this summer, Swedish raw material-to-steel company SSAB announced it had manufactured and delivered the ‘world's first fossil-free steel.' SSAB said it used HYBRIT technology developed by the joint venture it formed with Swedish state-owned miner Luossavaara-Kiirunavaara Aktiebolag and public power company Vattenfall. HYBRIT is raising interest among several companies and governments, including those of South Korea and India.

German hydrogen specialist Enapter this week celebrated the groundbreaking of its €105 million mass-production facilities for green hydrogen electrolyzers at its 82,000m2 campus in North Rhine-Westphalia, Germany. “Enapter is pursuing an initial goal of multiplying its production capacity to 10,000 electrolysers [per] month to satisfy the rapidly-growing demand for low-cost hydrogen-production solutions,” the company said on Tuesday. The development of the machinery necessary was supported by the North Rhine-Westphalia Ministry of Economic Affairs, Innovation, Digitalisation and Energy, with around €9.36 million. “From 2022, Enapter will offer the first megawatt-scale AEM Electrolyser – the containerized AEM Multicore – featuring 420 of its AEM electrolysis stacks,” added an Enaper press release. The company said its electrolyzers are used in 33 countries.

Popular content

The Abu Dhabi National Oil Company (ADNOC) British energy giant BP, and Abu Dhabi-based, state-owned renewables company Masdar have signed a strategic framework agreement to expand energy and climate collaboration between the UAE and U.K., including the potential development of hydrogen hubs in both nations at a scale of at least 2 GW. “Under the terms of the agreements, ADNOC, BP and Masdar will seek to collaborate on U.K. and UAE clean hydrogen hub development at an initial scale of 1 GW in the UAE and 1 GW in the U.K., building on the UAE’s position as an anchor investor in some of the U.K.’s largest offshore wind projects,” the partners said today. ADNOC and BP will also team up to develop greenfield carbon capture and underground storage facilities.

The Australian Renewable Energy Agency (ARENA) has awarded up to AUS$2.17 million (€1.35 million) to energy company Stanwell to complete a feasibility study for a hydrogen export project in Gladstone, Queensland. “The study, delivered in partnership with Japan’s largest hydrogen supplier, Iwatani Corporation, will investigate the feasibility of developing a hydrogen production facility capable of producing up to 36,500 tons per annum of renewable hydrogen and export[ing] to Japan from 2026,” stated a press release about the project. “Stanwell and Iwatani’s long term plan is to scale up to 328,500 tons per annum in 2031, to meet forecast Japanese demand. Stanwell proposes to ship hydrogen in liquid form, utilizing liquid hydrogen shipping vessels.” The AU$10.4 million (€6.4 million) study is also supported by Osaka-based municipal utility Kansai Electric Power Corporation; Japanese private businesses Marubeni Corporation and Kawasaki Heavy Industries; Australian energy business APA Group; and the Japanese Ministry of Economy, Trade and Industry.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.