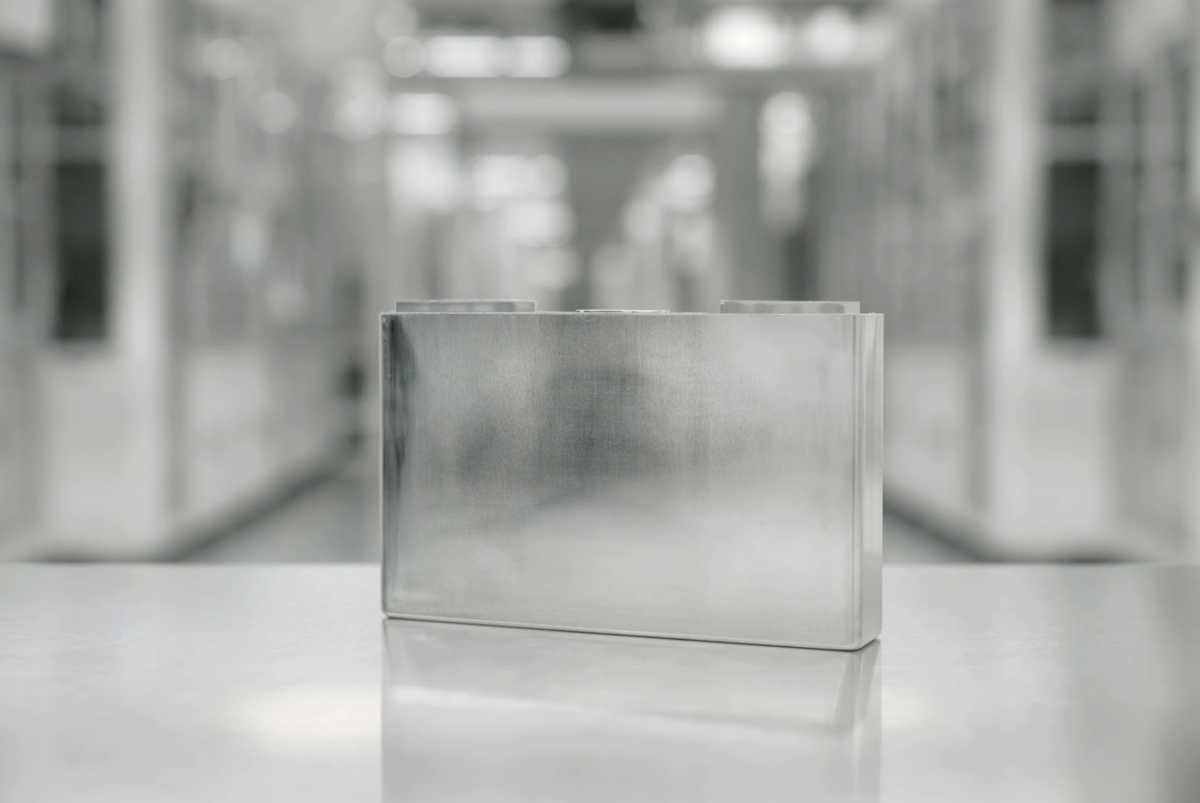

Northvolt celebrated the commissioning of its Northvolt Ett gigafactory on Tuesday with the assembly of its first European Li-ion battery cell.

“The cell is the first to have been fully designed, developed and assembled at a gigafactory by a homegrown European battery company,” said the company in a press release issued today.

The manufacturer has already secured $30 billion worth of contracts from customers including BMW, Fluence, Scania, Volkswagen, and Volvo Cars, and aims to begin commercial deliveries in the coming year.

Image: Northvolt

European gigafactory ramp up: A timeline

Keen to avoid the perceived mistakes of the solar cell and module industry, Europe has ambitious plans to establish a prominent domestic battery manufacturing presence.

Indeed, in 2018, the EU Battery Alliance, which was created a year earlier, called on industry to take advantage of the expected 2025 €250 billion battery market by building between 10 and 20 European giga factories for batteries.

According to Delta-EE this July, European Li-ion cell production capacity should increase tenfold by 2025, with 25 gigafactories planned for that year, and a further five already announced for 2030. This is said to translate into a total annual production capacity of around 591GWh by 2025.

“We have identified six gigafactories currently operational in the EU, equivalent to a total production capacity of Li-ion cells of 62GWh. By 2025, this is expected to increase to 25 plants and a production capacity of around 591GWh, and reaching 664GWh by 2030,” wrote Delta-EE analyst João Coelho in the July edition of pv magazine.

He added that Germany has both the highest number of planned gigafactory plants by 2030 (nine projects) and a planned capacity almost three times larger than Hungary, the next largest. “Tesla, Northvolt and LG Chem are expected to grasp 32% of the total share of European Li-ion cell capacity by 2030, with further potential for Northvolt involvement in future projects for Skoda.”

On the ground

Northvolt also appears to be a central part of Europe’s battery manufacturing plans. The company, established in 2016 by Swedish entrepreneur Peter Carlsson, aims to secure 25% of Europe’s battery market by 2030 – with an estimated 150GWh of annual manufacturing capacity.

In Sept. 2017, it announced that Switzerland’s ABB had signed a Memorandum of Understanding (MoU) to supply and support a new lithium-ion battery factory being built in Sweden by Northvolt. At that time, production was expected to begin in 2020.

The following year then saw a flurry of financing announcements by Northvolt. They started in Jan. with the news that Scania, a truck manufacturer owned by Germany’s Volkswagen, pledged €10 million in the factory. In February, it then received a further around €15 million from the Swedish Energy Agency (Energimyndigheten). The same month, the company was approved for a European Investment Bank (EIB) loan of up to €52.5 million to support Northvolt’s pilot demonstration plant in Västerås.

In October 2018, Northvolt then announced plans for a manufacturing plant in Gdansk, Poland. The company said it would have an initial capacity of 10,000 battery modules per year and would begin production in 2019.

A year later, in June 2019, it secured $1 billion in equity funding for the construction of its Swedish venture, taking total funding to €3 billion. At that time, the Northvolt Ett fab, located in Skellefteå, Sweden, had the goal of producing 40GWh of batteries by 2020.

On the same day, it also announced the formation of a 50-50 joint venture fab with Volkswagen in Germany, named The Northvolt Zwei Factory, which would manufacture 20GWh of batteries per year.

Not one to be left behind, in November 2019, Tesla CEO Elon Musk said the company would build its fourth global gigafactory in Berlin Brandenburg, Germany. The factory was scheduled to open in the summer of 2021; however, no news has been reported on the project since 2020, when Musk published a rendering of the planned facility.

Image: https://twitter.com/elonmusk

News was quiet for a while, until July 2020, when Northvolt again attracted another impressive financial boost, this time from an assortment of public finance institutions, commercial banks and pension funds which allocated $1.6 billion in debt financing for its Swedish and German factory plans.

Following on from this, in August 2020, French start-up Verkor – with the help of EU-funded sustainable energy research body EIT InnoEnergy, energy and automation digital solutions company Schneider Electric and Paris based engineer IDEC Group – said it intended to set up a battery fab, with production to start in 2023 with an initial annual manufacturing capacity of 16GWh which could rise to 50GWh, depending on demand.

The 200ha factory would cost an initial €1.6 billion and would create more than 2,000 jobs while supporting thousands more in its supply chain, according to Verkor.

Entering a new year, in February 2021, Verkor then announced that French industry consultant Capgemini had joined the project to improve the manufacturing process and that the fab would be located in Rodez, about 150km northeast of Toulouse, in the Occitanie department of Aveyron.

Image: Verkor

Italian start-up Italvolt also announced in Feb. that it wants to build a €4 billion EV battery manufacturing facility in Italy. The site for the project is currently being identified, and the factory’s initial capacity should reach 45GWh. The project's first phase is expected to be finalized by the end of 2024.

Image: Italvolt

Not to be outdone, Northvolt stepped up its game once again, announcing the same month that it would invest another $200 million in its Polish production facility. The start of production is planned for 2022 with an initial output of 5GWh and, at a later stage, the capacity could be raised to 12GWh, it said at the time, adding that a new research and development center would also be set up in conjunction with the expansion plan.

The following month, the Spanish Minister of Industry, Commerce and Tourism, Reyes Maroto, announced that the government intended to create a public-private consortium led by car manufacturer SEAT-Volkswagen and Spanish energy company Iberdrola to set up the first EV battery factory in Spain. No time frame nor specific investment figures for the project were provided, but the minister said it would be “the first battery factory in Spain” and located close to the SEAT factory in Martorell, near Barcelona, in the region of Catalonia.

Also in March, Volkswagen announced a strategic alliance with Iberdrola to expand electrification in Spain, in addition to tie-ups with Italian utility Enel and UK energy group BP in Europe, as well as other partners such as Ionity and Aral. In addition to the main goal of supplying renewable energy for the electric-vehicle value chain, the companies said they aim to develop a public charging infrastructure network and build up to six gigafactories in Europe, with a total production capacity of 240GWh. The first two factories are expected to operate in the Swedish city of Skellefteå and in Salzgitter, Germany (namely the Northvolt factories).

In June 2021, Northvolt came along with the announcement that it was planning to raise $2.75 billion through a private placement to expand the capacity of its Swedish manufacturing site from 40GWh to 60GWh.

Finally, last month, the manufacturer announced that its recycling program, Revolt, had produced the first lithium-ion battery cell featuring a nickel-manganese-cobalt (NMC) cathode produced with metals recovered through the recycling of battery waste.

“The recycling process can recover up to 95% of the metals in a battery to a level of purity on par with fresh virgin material. What we need now is to scale-up recycling capacities in anticipation of future volumes of batteries requiring recycling,” said Emma Nehrenheim, Northvolt’s Chief Environmental Officer and head of Revolt, at the time.

Via Revolt Ett, Northvolt is also working on a giga-scale recycling plant located adjacent to the Northvolt Ett gigafactory.

“With construction beginning in Q1 2022 and operations in 2023, the recycling plant will receive incoming material for recycling from two sources: end-of-life batteries from electric vehicles and production scrap from Northvolt Ett,” read the press release.

It says that recovered materials from Revolt Ett will supply the neighboring factory with recycled metals sufficient for 30GWh of battery production annually.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

When will northvolt shares be available & average cost