German and U.S.-owned energy storage heavyweight Fluence has entered into a multi-year agreement with U.S. battery start-up QuantumScape to introduce solid-state lithium-metal battery technology in stationary storage applications. The deal has made Fluence the first non-automotive company to partner with the start-up.

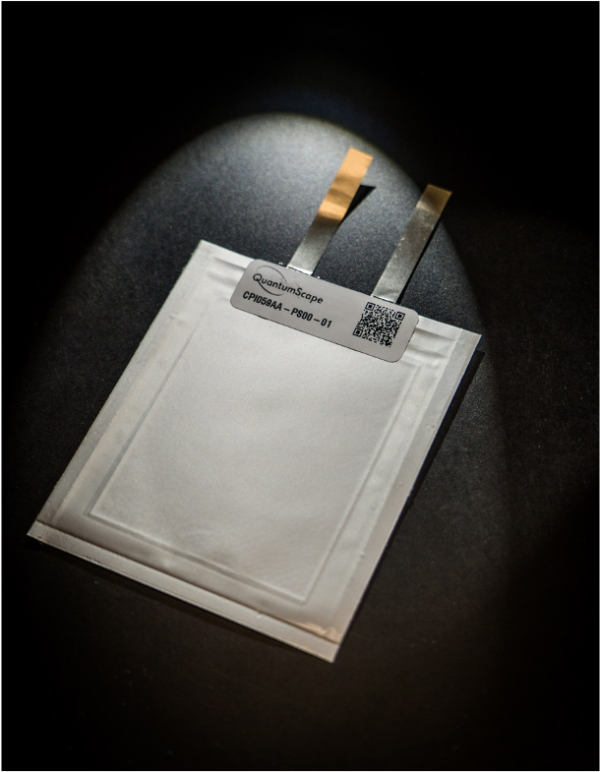

The agreement, which reserves batteries produced by QuantumScape’s pre-pilot production facility, QS-0, will see the companies work together to validate and test QuantumScape’s solid-state battery cells for use in Fluence’s proprietary stationary storage products. The companies expect to enter into a large-scale supply agreement during their collaboration.

“Fluence’s technology-agnostic platform is also particularly suited to early adoption of next-gen technologies like this that have the potential to increase the adoption of stationary storage,” said Manuel Perez Dubuc, CEO of Fluence.

Solid-state battery tech holds the promise of higher energy density, reduced charge time and improved safety compared to their liquid-filled cousins, li-ion batteries. But the hard part about making a working solid-state battery is to simultaneously meet all the requirements in terms of density, charge, lifespan, wide operation temperature range and cost.

In 2020, QuantumScape claimed it had made this happen and reported breakthroughs in the solid-state lithium-metal technology, including increasing energy density by 50% to 100%. At the time, the 10-year-old start-up was already backed with $1.5 billion from a long list of investors, including Volkswagen and the Bill Gates-led Breakthrough Energy Ventures, among others.

The company’s solid-state design uses no manufactured anode. Namely, as the battery charges, the lithium moves from the cathode through aceramic separator and deposits between the separator and an electric contact plate, forming an anode of metallic lithium in situ.

QuantumScape uses a proprietary solid-state ceramic separator, which is touted to be capable of meeting the key requirements of high conductivity, stability to lithium metal, resistance to dendrite formation, and low interfacial impedance. These are the key requirements to make a lithium-metal anode with zero excess lithium, which in turn enables high energy density, fast charge, and long life.

The ceramic separator also enables the use of a customized catholyte material, better suited for the voltage and transport requirements of the cathode, according to QuantumScape.

The ceramic itself is non-combustible, making it safer than conventional polymer separators, which are hydrocarbons and can burn. It uses earth abundant materials with a continuous-flow manufacturing process, which could make it cost-effective at commercial volumes.

The company says its single layer cells were tested to over 1,000 charge-discharge cycles and have maintained approximately 90% capacity. The energy density of its cells stands at 1,000 Wh/L.

“While we have historically focused on automotive applications, we believe our battery technology is broadly applicable and can play a role in other sectors contributing to a lower-carbon future,” CEO Jagdeep Singh said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Marija,

Could you point us to the source of 1000 Wh/L energy density.

Is it the number published by QuantumScape?

Is it the test results confirmed by QuantumScape?

Thanks.

Yes, this is their target density they say they can achieve by stacking together several dozen of their single layer unit cells. You can find more info here: https://www.quantumscape.com/blog/a-discussion-of-quantumscapes-battery-technology-performance-results/