Scientists in South Korea have fabricated a shape-transformable 3D PV system based on tessellated solar-cell units that is claimed to be an ideal solution for both urban and rural environments with limited areas for the deployment of photovoltaics.

The proposed system is based on shape-memory-alloy components that act as actuators, based on the solar cell temperature, to automatically adjust the shape of the array in response to the sun’s position, with no need for machinery. “The cross-sectional area perpendicular to the incident light increases as the actuator flattens the panels, facilitating an automated solar-tracking effect,” the researchers explained. “In addition, this solar-tracking concept can be applied to tessellated modules, which have the advantage that they use widely available commercial crystalline silicon (Si) solar cells.”

According to the research team, the PV system is able to increase electricity yield by 60% over a day compared to a fixed flat panel due to the shorter shadow length and the bifacial effect obtained during shape transformation. “Direct light is gathered effectively on some surfaces and scattered and reflected light is gathered on other surfaces, an effect that cannot be obtained in solar modules that use conventional tracking systems,” they emphasized.

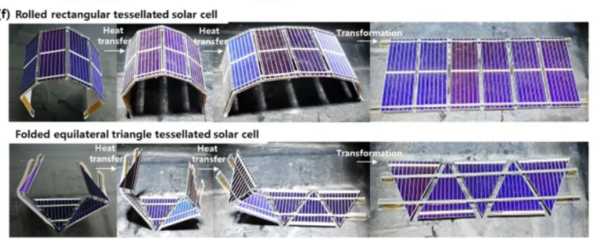

The solar cells were cut in a range of shapes such as rectangles, equilateral triangles and right-angled triangles, with silicone rubber or a metal mesh being used as the backbone to create the 2D arch shape. The cells were placed on the backbone strip at regular intervals and were connected using metal wire or textile electrodes and soldering. The shape-memory-alloy strips were made with nickel-titanium shape-memory alloy and applied to the surface of each solar cell panel. The tessellated solar cells were then encapsulated in a silicone material using a casing method.

Image: Korea Electrotechnology Research Institute, scientific reports, Creative Commons License CC BY 4.0, https://bit.ly/3HgkG09

The researchers pointed out that, in the tessellated modules, the transformation of the solar-cell array is triggered by the shape-memory-alloy components between the tessellation units and in the linkage spaces. “Therefore, the temperature of the shape-memory-alloy components between the solar-cell surfaces is more important than the temperature of the surfaces themselves,” they also said. “The temperatures of the shape-memory-alloy components located between the solar-cell units at a distance of 3 mm from the cell surface and that of the linkage backbone follow a similar trend to the temperature of the solar cell surface, but with values that are 2–6 °C lower.”

Popular content

The device was tested under standard illumination conditions and its performance was compared to that of conventional fixed flat panels. The system efficiency was evaluated based on the maximum power output from the array per unit installed area.

The output power of the tessellated solar-cell arrays was found to drop with increasing angle of incidence (AOI) or decrease when following the cosine of the AOI. “However, the superior solar-tracking performance of the shape-transformable 3D tessellated solar-cell arrays was little affected by the AOI,” the Korean group specified, noting that the installed-area-based efficiency was raised by the shape-transformable solar tracking in all cases. “The efficiency of shape-transformable tessellated solar-cell arrays with respect to the installation area can provide superior omnidirectional performance compared to flat fixed solar panels.”

Tight-angled triangle-shaped solar cells showed the best performance in the short arch and offered superior performance under omnidirectional incident light. “The part of the array that is self-shaded during shape transformation acts as the reverse side of a bifacial photovoltaic module, providing shape-transformable tessellated solar-cell arrays with the advantages of both a solar-tracking system and a bifacial PV module,” the scientists concluded. “This study introduces the shape-transformable photovoltaic module concept; many more areas of research remain, including efficient power management of each cell and 3D designs suitable for specific applications.”

The cell technology was introduced in the paper “Automated shape-transformable self-solar-tracking tessellated crystalline Si solar cells using in-situ shape-memory-alloy actuation,” published in scientific reports. The research group is formed by scientists from the Korea Electrotechnology Research Institute and the University of Science and Technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.