Lithium metal batteries could offer far better energy density and much lower weight than lithium-ion technology thanks to the replacement of heavier graphite with lithium metal as anode. However, one of the biggest challenges in the design of these batteries is the formation of dendrites on the anode’s surface, causing the battery to rapidly degrade, short, and even catch fire.

Researchers at Harvard John A. Paulson SEAS have developed a new lithium metal battery that withstand at least 6,000 charging cycles and can be recharged in a matter of minutes.

Their research not only describes a new way to make solid state batteries with a lithium metal anode but also offers new understanding into the interface reaction between lithium and materials at the anode in these type of batteries.

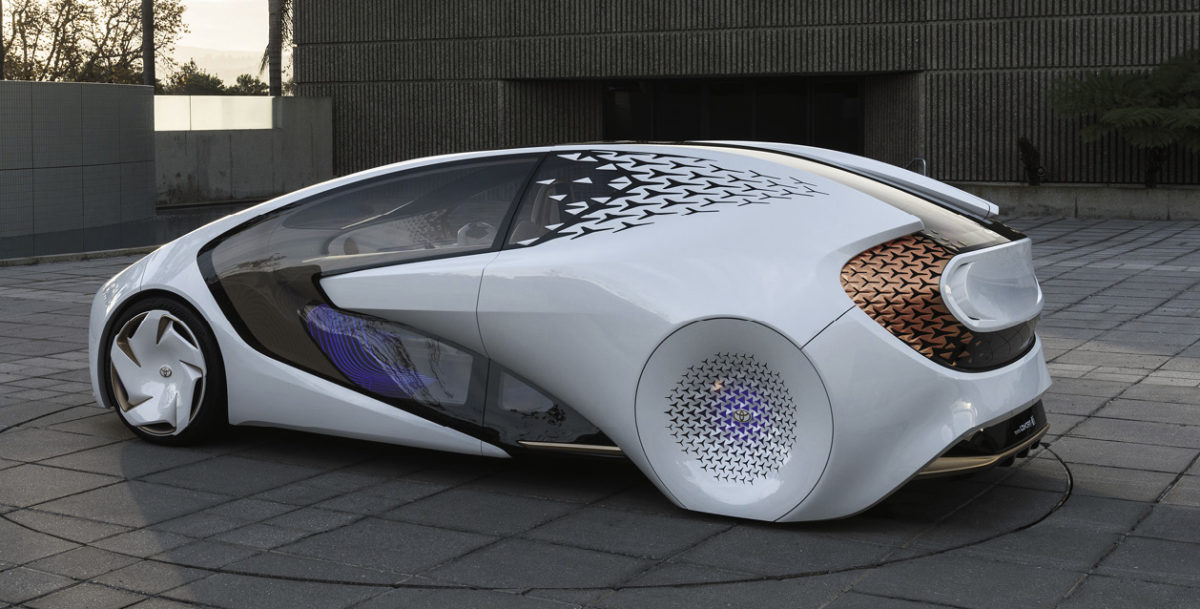

“Lithium metal anode batteries are considered the holy grail of batteries because they have ten times the capacity of commercial graphite anodes and could drastically increase the driving distance of electric vehicles,” said Xin Li, Associate Professor of Materials Science at SEAS and senior author of the paper. “Our research is an important step toward more practical solid-state batteries for industrial and commercial applications.”

In 2021, Li and his team offered one way to deal with dendrites by designing a multilayer battery that sandwiched different materials of varying stabilities between the anode and cathode. This multilayer, multi-material design prevented the penetration of lithium dendrites not by stopping them altogether, but rather by controlling and containing them.

In the new research, Li and his team stop dendrites from forming by using micron-sized silicon particles in the anode to constrict the lithiation reaction and facilitate homogeneous plating of a thick layer of lithium metal.

In this design, when lithium ions move from the cathode to the anode during charging, the lithiation reaction is constricted at the shallow surface and the ions attach to the surface of the silicon particle but do not penetrate further.

“In our design, lithium metal gets wrapped around the silicon particle, like a hard chocolate shell around a hazelnut core in a chocolate truffle,” said Li.

These coated particles create a homogenous surface across which the current density is evenly distributed, preventing the growth of dendrites. And, because plating and stripping can happen quickly on an even surface, the battery can recharge in only about 10 minutes.

The researchers built a postage stamp-sized pouch cell version of the battery, which is 10 to 20 times larger than the coin cell made in most university labs. The battery retained 80% of its capacity after 6,000 cycles, outperforming other pouch cell batteries on the market today, the reserchers reported in Fast cycling of lithium metal in solid-state batteries by constriction-susceptible anode materials published in nature materials.

The technology has been licensed through Harvard Office of Technology Development to Adden Energy, a Harvard spinoff company cofounded by Li and three Harvard alumni. The company has scaled up the technology to build a smart phone-sized pouch cell battery.

Li and his team also characterized the properties that allow silicon to constrict the diffusion of lithium to facilitate the dynamic process favoring homogeneous plating of thick lithium. They then defined a unique property descriptor to describe such a process and computed it for all known inorganic materials. In doing so, the team revealed dozens of other materials that could potentially yield similar performance.

“Previous research had found that other materials, including silver, could serve as good materials at the anode for solid state batteries,” said Li. “Our research explains one possible underlying mechanism of the process and provides a pathway to identify new materials for battery design.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

So similar dilithium crystal from Star Trek

The main concern is can that really be used in EVs in mass production? What are the cost differences? How do they affect the EVs performance?

Just coming up with something better in some ways does not mean that we can see them in EVs!

Who mentioned EVs? They don’t use pouch batteries, they use standard cells. Cell phones and similar use pouch batteries.

Maybe this will reach electric vehicles one day. But I’d rather have 6000 charges and a 10 minutes charge time for my phone!

Thank you for the storey Marija.

Interesting. I am sure this will save ones time and hopefully you will as wel cosider, the price, so that it will reach to the wider consumer.