Researchers from the Korea Institute of Machinery and Materials have proposed to combine adiabatic compressed air storage (A-CAES) and large scale solid-oxide electrolysis cells (SOEC) for the production of green hydrogen via excess power from wind and solar PV facilities.

A-CAES can store compression heat or compressed air in thermal energy storage (TES) and air storage reservoirs, respectively, and then release the heat and compressed air for power production. It differs from conventional CAES for implementing the process “adiabatically,” which means without loss or gain of heat. SOECs use a solid oxide – or ceramic – electrolyte to produce hydrogen and syngas fuel (CO+H2) from a mixture of water and carbon dioxide or oxygen from carbon dioxide, respectively.

“The A-CAES system can be used as a combined cooling, heat and power (CCHP) system, providing heat and power to SOEC in order to maximize the energy efficiency of the system,” the scientists explained. “Unlike the diabatic CAES system with an external heat source, in the case of the A-CAES system, heat is recovered from compression, stored in a TES unit, and later used to heat the compressed air for the expansion process.”

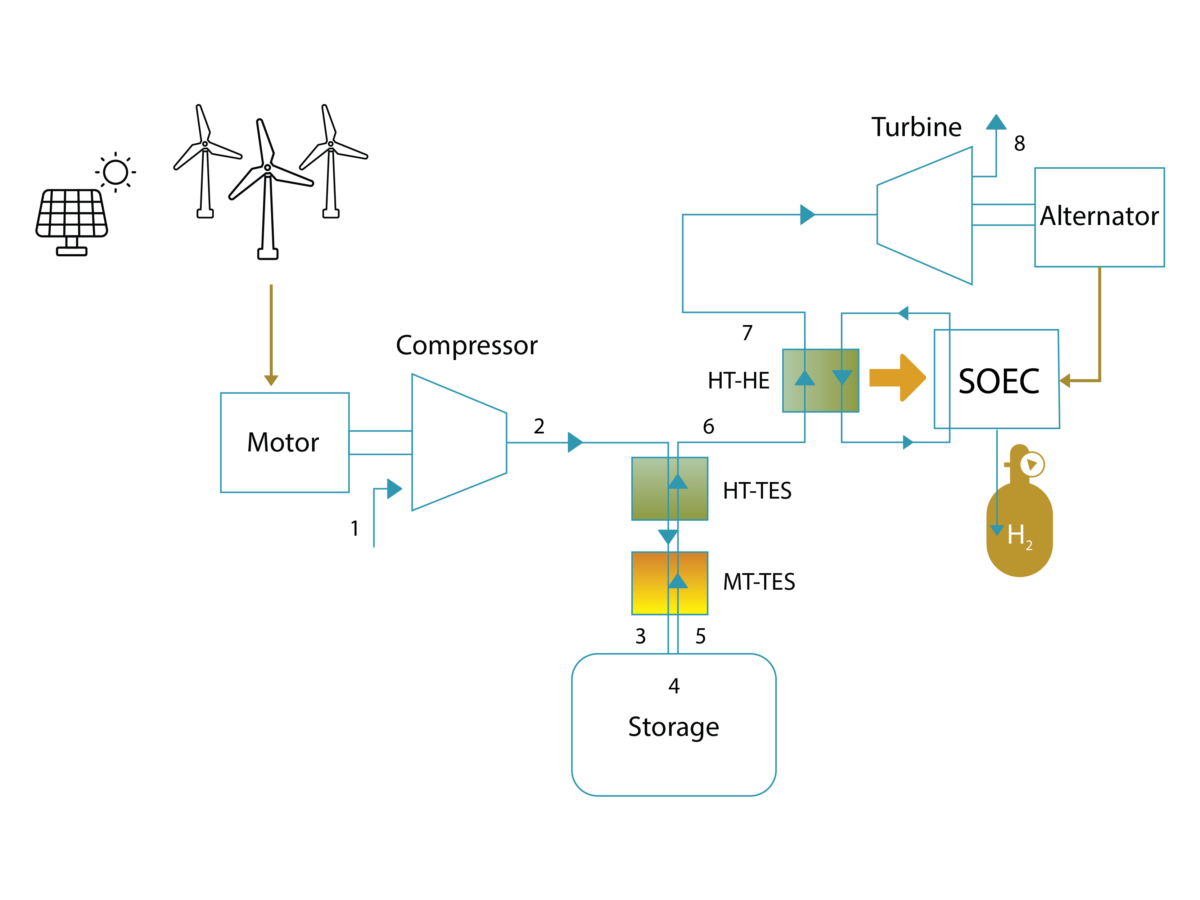

The system consists of a motor, a compressor, and TES units, which are connected to both a turbine for power generation and the SOEC unit. It cools hot compressed air in the TES unit and then stores it in large underground caverns. In the discharging process, the compressed air is released from the cavern and heated by the TES. The hot compressed air is then conveyed to the expander for power generation or to the SOEC unit.

“The TES unit is divided into high-temperature (HT) and medium-temperature (MT) units for efficient use,” the group said. “During the discharging process, compressed air heated by the TES unit supplies external heat to the SOEC system via a high-temperature heat exchanger (HT-HE).”

The academics analyzed the performance of the system considering constant-pressure air storage, negligible potential and kinematic energy effects, as well as a minimum temperature difference of 10 C for heat transfer between the TES and the air. They also assumed the compression pressure of air to be constantly at 70 bar, while the compression power was assumed to be 100 MWh, with the charging and discharging periods being identical.

Popular content

The analysis showed that the system has a round-trip efficiency of approximately 70% and that the remaining 30% of the input energy was dispersed as heat due to the “irreversibility” of the A-CAES processes.

“When the A-CAES system is integrated with a SOEC, the thermal energy from the A-CAES can be used to vaporize water in the SOEC electrolyzer,” the researchers stressed, noting that the SOEC unit can operate for 24 h regardless of the discharging or charging modes. “With an increase in the use of the thermal energy of A-CAES for SOEC, although the round-trip efficiency of electricity decreases, the CHP round-trip efficiency increases to more than unity.”

The total round-trip efficiency of the CCHP-A-CAES system was found to be 121.2% and its over-unity efficiencies were in the range of 100% to 120%. “Thermo-economic modeling and optimization of the proposed systems, considering both energy efficiency and economic factors, would provide valuable insight on the best ways to implement them in real-world applications,” they concluded.

The proposed system was introduced in the paper “Adiabatic compressed air energy storage system combined with solid-oxide electrolysis cells,” published in Energy Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.