A research group led by scientists from Ethiopia's Mattu University has developed and analyzed a solar cabinet dryer for mango slices, with PV-powered forced convection. To address the poor thermal efficiency of previously reported cabinets, the team has included rectangular baffles in the setup.

“Built using locally available materials, the cabinet-style dryer is optimized for smallholder farmers in low-income settings, delivering both affordability and high-quality dried products through shorter drying times and controlled drying conditions,” corresponding author Ermias A. Tesema told pv magazine. “The baffled design improved energy efficiency, enhancing airflow and drying uniformity. This leads to faster drying with better product quality using clean, renewable solar technology.”

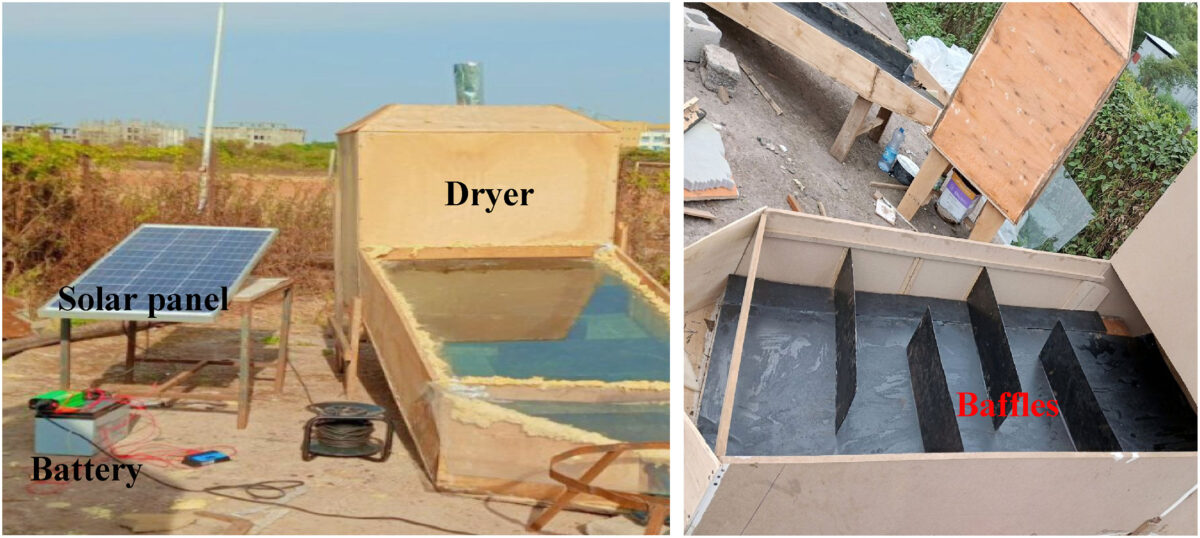

The solar cabinet was constructed out of 18 mm-thick wood plates, with 0.8 mm steel sheets used as absorber plates. The collector had a length of 1.6 m and a width of 90 cm, with four rectangular baffles measuring 67.5 cm. The drying chamber included three trays with a length of 60 cm and a width of 90 cm, with a chimney of 50 cm. A PV module and a battery were placed next to the structure, powering an air heater and a fan.

Mango slices with thicknesses of 3 mm, 5 mm, and 7 mm were prepared for the experiment. Each mango's thickness was tested under different scenarios, namely, in a solar cabinet with baffles, in a solar cabinet without baffles, and via the open-sun drying technique. The experiments took place in Bahir Dar, northern Ethiopia, from September to December, with the mangos being ripened for five days before drying.

“The baffled dryer achieved a thermal efficiency of 29–30%, a notable improvement over typical non-baffled designs. Using baffles and thinner slices (3 mm) significantly improved vitamin C retention (up to 25.55 mg/100 g), rehydration ratio (4.27), and color preservation, while reducing drying time by up to 2 hours compared to the non-baffled version,” said Tesema. “An unexpected finding was that open-sun drying yielded the highest phenolic content, likely due to heat-induced formation of new phenolic compounds.”

Concluding, Tesema said that “future work will focus on further optimization of baffle geometry and positioning using Computational Fluid Dynamics (CFD) modeling to maximize airflow uniformity and heat transfer. We also aim to integrate hybrid energy sources such as biomass or photovoltaic backup for continuous drying during cloudy or nighttime conditions, and to evaluate the system with other tropical fruits like pineapple and papaya.”

The system was presented in “Design, development, and performance evaluation of baffled solar mango slice dryer,” published in Case Studies in Thermal Engineering. Researchers from Ethiopia's Mattu University, Bahir Dar University, Oda Bultum University, and Germany's Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB) have participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.