Researchers from Germany's Forschungszentrum Jülich have demonstrated that heterojunction (HJT) solar cells metalized with copper (Cu) paste or copper-silver (AgCu) paste can achieve efficiency levels comparable with those of PV devices metalized with Ag alone.

They explained that the HJT design is the most suitable for reducing or eliminating silver use in solar cells, as the transparent conductive oxides (TCO) used in this architecture serve as barriers to prevent the diffusion of copper into silicon.

“Cu is a viable alternative to Ag, and proves that the sustainable PV development target of Ag usage of 2 mg/W by 2030 is realistic,” the research's corresponding author, Kaining Ding, told pv magazine. “Now we plan to introduce silver-free metallization into full solar modules and perform reliability and stability studies under damp heat and thermal cycling conditions. Furthermore, we want to support paste companies to develop new ideas and optimize existing approaches to make Cu paste production more cost competitive than AgCu paste.”

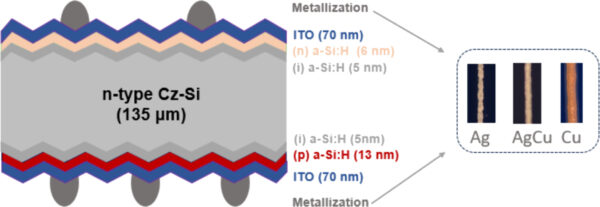

The research team investigated, in particular, three different cell designs: with metallization based exclusively on Cu; with AgCu metallization; and with Ag metallization. Screen printing (SP) and dispensing were used for building the metal contacts, with the second technique being labeled as needing low silver consumption capacity while having a high aspect ratio.

“We metalized the front and rear sides of the cells with Ag, AgCu, and Cu paste and compared them. Additionally, finger characteristics such as width, height, line resistance, contact resistance, and bulk resistance were evaluated,” the academics explained, noting that the tests were conducted on 244.32 cm2 bifacial solar cells with a wafer thickness of 135 μm. “We first examined the performance of screen printed and dispensed fingers from the three different pastes on one side of the wafer.”

Image: Forschungszentrum Jülich, Progress in Photovoltaics, CC BY 4.0

They used the same screen design and 96 fingers with a pitch of 1.6 mm for all three pastes. Furthermore, they utilized single-nozzle dispensing to print them. The Ag and AgCu fingers were annealed with an oven and the Cu fingers with a hot plate.

The manufacturing process was carried out at a temperature of 250 C, although Cu paste metallization usually requires 300 C, with the researchers identifying the degradation threshold at temperatures exceeding 280 C for 5 s.

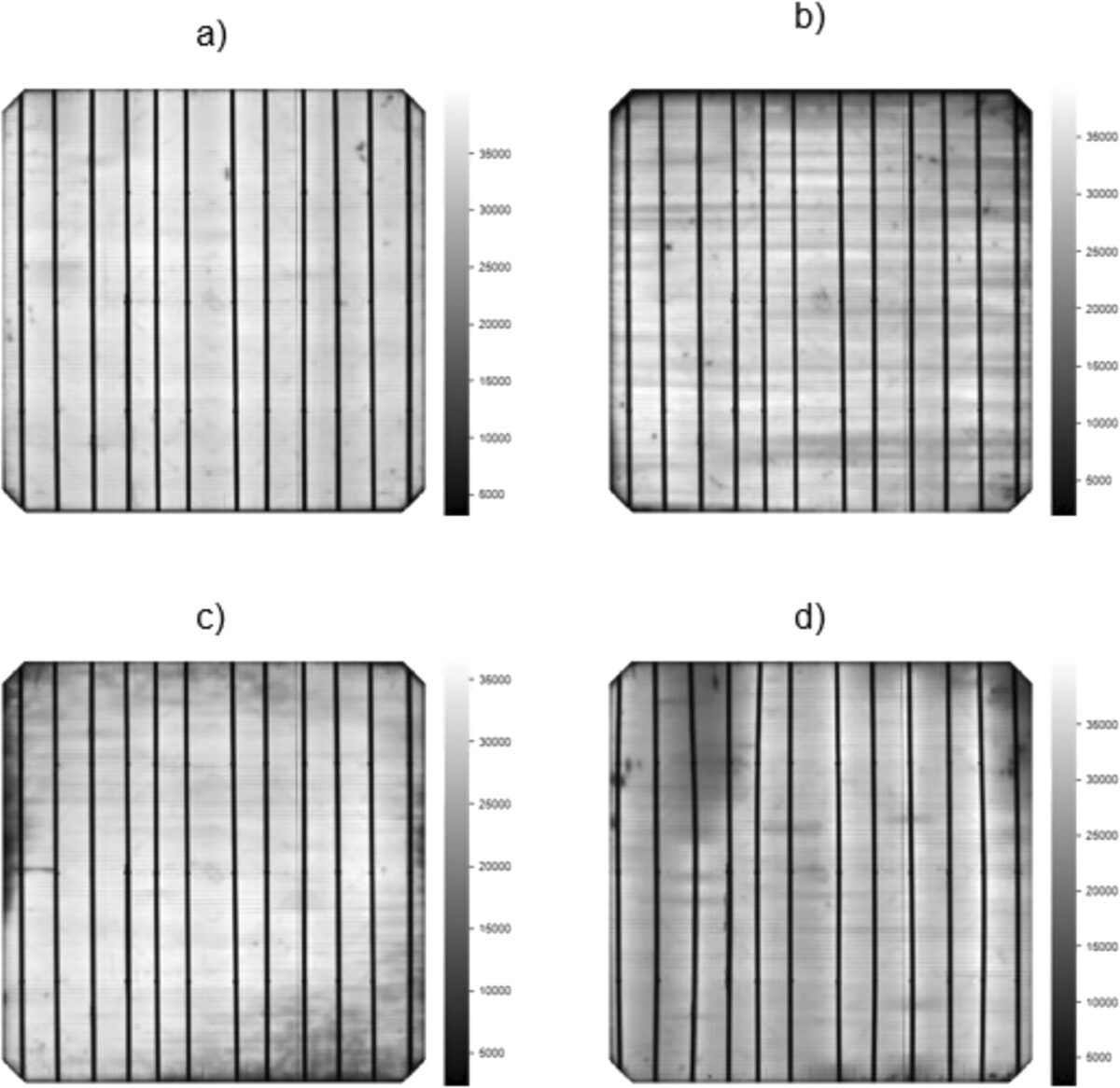

The analysis showed that the cells screen-printed with AgCu paste on the front and Ag paste on the rear side achieved an average efficiency improvement of 0.13% absolute compared to benchmark Ag screen-printed bifacial devices.

“Cells with screen-printed AgCu on the front and screen-printed Cu on the rear side reached an efficiency of up to 23.6% absolute, only 0.35% lower than reference cells, while saving approximately 70% of Ag paste,” the academics stressed. “Notably, cells with screen-printed Cu on both sides achieved an average efficiency of 22.4% absolute and a maximum of 23.08% absolute, representing the highest performance recorded for cells with screen-printed Cu on both sides and zero Ag.”

They also found that Cu dispensing on the rear side achieved a better performance than Cu SP.

“To maximize the potential of AgCu and Cu pastes, it is essential to optimize and standardize Cu screen printing and dispensing processes, reduce dispensed finger widths, and conduct further research on printing processes, stability, reliability, and economic benefits,” they concluded.

Their findings can be found in “Achieving High Efficiencies for Silicon Heterojunction Solar Cells Using Silver-Free Metallization,” published in Progress in Photovoltaics.

Another research team at Forschungszentrum Jülich has recently proposed to use direct wire bonding (DWB) as a low-temperature method for interconnecting finger-free HJT solar cells on the front side using low-cost, highly conductive Cu wires. Their analysis showed that a solar module built with the proposed solar cells achieved a power conversion efficiency of 20.19%, which compares to 20.43% for a benchmark panel constructed with six conventional tabbing wires on the front side.

This month, researchers from Ghent University in Belgium and the Engie Laborelec unit of the French energy giant have announced they investigated how much silver could be needed by the PV industry by 2030 and have found that silver shortages may become more frequent.

Their analysis showed that total silver demand is projected to reach 48,000 to 52,000 t/y in 2030, with supply being enough to reach only 34,000 t/y. The PV industry, meanwhile, is projected to see its silver demand grow by a factor of 1.6 to 2.3 to 10,000–14,000 t/y in 2030, as a consequence of higher silver consumption in new cell designs such as TOPCon and HJT. “As a result, the silver demand of the PV industry could account for 29–41 % of the projected supply in 2030,” they emphasized.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.