From pv magazine Spain

Spanish engineering group Táctica Industrial has introduced an off-grid photovoltaic-to-hydrogen system designed to produce green hydrogen at an estimated €400/kW using modular alkaline electrolyzers without inverters or grid connection.

The company said the system generates and consumes hydrogen on-site through an off-grid PV plant linked to modular electrolyzers integrated into medium-voltage direct-current microgrids using power-to-gas technologies.

“It’s a scalable, modular solution that starts with a photovoltaic plant dedicated to continuously powering the system, without the need for a grid connection for transmission or distribution,” José Luis Sierra Suárez, manager of the corporate group, told pv magazine. “Today in Spain, anyone with a photovoltaic system has a small power plant.”

The company said the approach builds on long-standing industrial experience. “Taking advantage of the robustness, reliability, and durability of alkaline electrolysis, we have incorporated technological advances that increase efficiency and adapt the technology to current production needs,” said Sierra.

Green hydrogen generation takes place at the electrical output through the electrolysis system developed by Sinfin Energy, a subsidiary of the group. The electrolytic cell converts renewable electricity into the energy required to split water molecules into hydrogen, collected at the cathode, and oxygen, at the anode. Both gases are recovered separately after drying and separation.

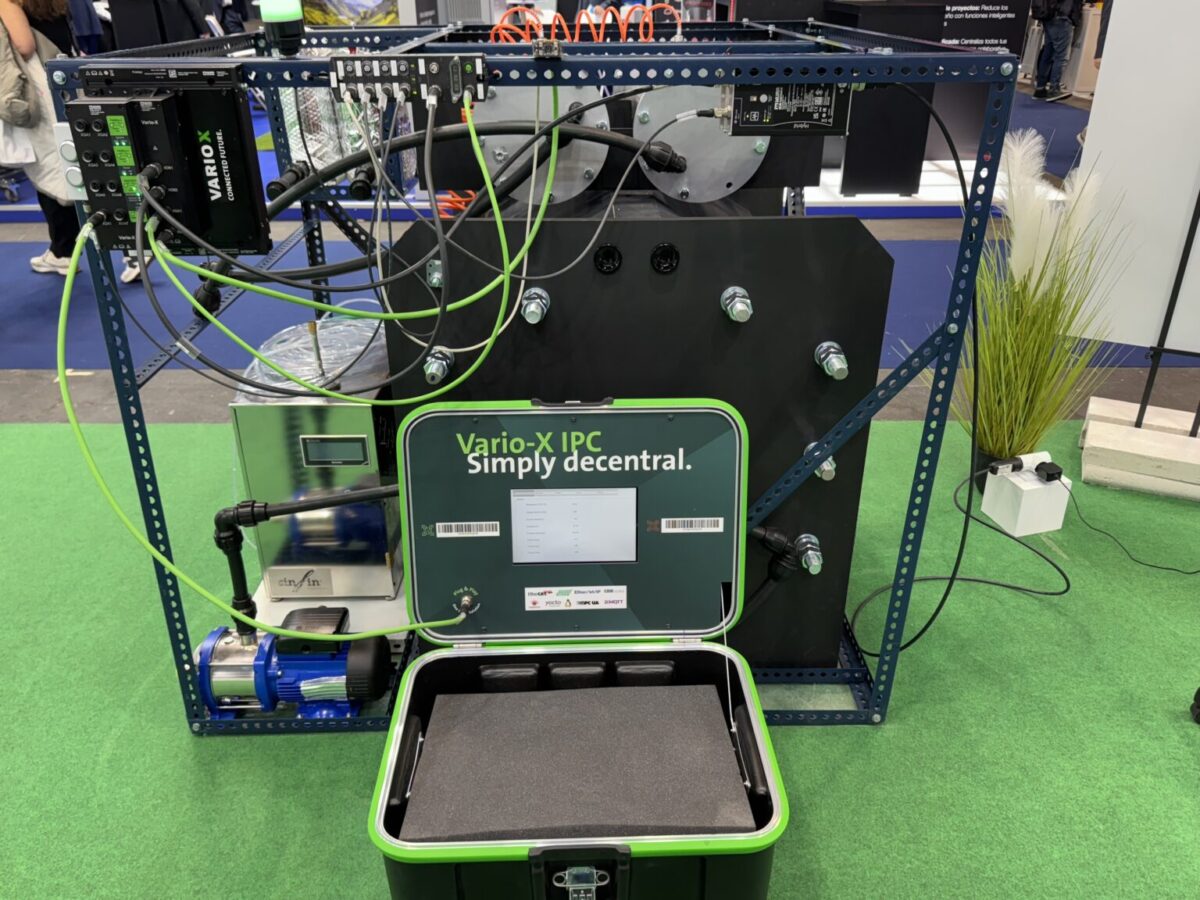

The modular stack allows each unit to be operated and controlled independently.

The PV plant can surpass 200 MW of installed capacity. The system operates with a 250 kW electrolyzer module producing 60 Nm³/h of hydrogen. According to Táctica Industrial, the platform uses “an innovative control architecture in which all operating parameters – voltage, current, electrolyte flow and current density – are monitored and managed individually and automatically.” The company said this enables each unit to adjust its load independently.

The modular architecture supports multiple configurations and allows the plant to adapt to variable renewable output. Integrating several units in one facility reduces production, maintenance, and dismantling costs. The company estimates hydrogen production costs via alkaline electrolysis at €400/kW.

The system can be coupled with downstream hydrogen uses, including synthetic fuels such as ammonia.

According to the developers, the technology “has been validated at small scale, and is market-ready.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.