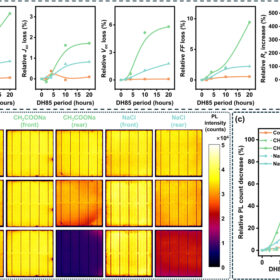

New research shows degradation mechanisms in rear side of TOPCon solar cells

Researchers from UNSW and Longi have found that the silicon nitride layers used in TOPCon cell rear-side are particularly prone to chemical degradation from sodium contaminants. This can lead to significant open-circuit voltage losses and reduce cell efficiency.

Dutch consortium seeks to reduce costs of hole transport layers for perovskite solar cells

Two Dutch manufacturers have teamed with TNO’s perovskite solar cell experts to integrate spatial atomic layer deposition equipment to produce ultra-thin, high-quality nickel-oxide hole transport layers in a roll-to-roll process. The team targeting production integration in mid-2027, with full-scale production by 2030.

Pricing and technology trends for US solar panel resale market

A strong market exists for wholesale secondary market solar modules, says EnergyBin.

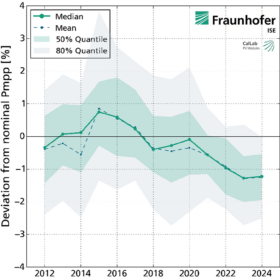

Fraunhofer ISE research finds solar module output ‘often overstated’

A longitudinal research project from the Fraunhofer Institute for Solar Energy Systems ISE reveals that since 2017, the institute has measured less power on average in a solar module than promised by the manufacturer.

Aiko launches 500 W C&I back-contact solar module with 25% efficiency

The Chinese manufacturer launched its new Infinite panel at the Solar Solutions Amsterdam event in the Netherlands. The module measures 1,762 mm x 1,134 mm x 30 mm and has a temperature coefficient of -0.26%/C.

Nigeria plans 1.2 GW solar module assembly plant

Nigeria’s Rural Electrification Agency has entered into an agreement with Oando Clean Energy for a 1.2 GW project consisting of an off-grid power plant, mesh electricity generation, interconnected power grid and solar manufacturing power plant. A 600 MW line is scheduled to be rolled out next year.

Autowell Technology unveils 0BB tool for multiple silicon PV module technologies

The equipment with a processing speed of up to 10,800 pcs/h can be used to upgrade existing super multi-busbar (SMBB) and multi-busbar (MBB) equipment made by China-based Wuxi Autowell Technology (ATW). It is suitable for tunnel oxide passivated contact (TOPCon), heterojunction (HJT), and back-contact (BC) cell technologies.

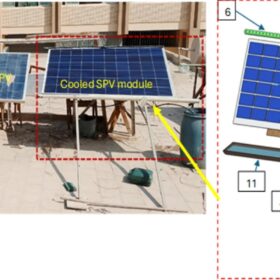

Experimental system cools PV panels while keeping them clean

Researchers had placed a cotton sheet on the back of a PV module, which was then made wet and cooled. On the front side, water was pumped water from a pipe in a way that kept the panel both cool and clean. Their experimental setup showed superior results compared to reference cooling technologies.

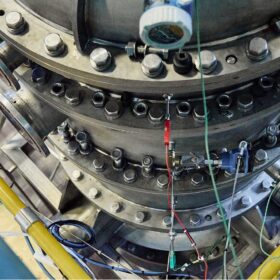

Startup shipping high purity silicon samples from pilot plasma reactor

Sweden’s Green14 is sampling material from its pilot reactor at KTH Royal Institute of Technology. The pilot has a 100 kW plasma capacity with 5 kg/h of silicon.

Replacing silver in PV manufacturing with new graphene electrode technology

Swiss-British university spinoff, GraphEnergyTech, is developing graphene electrode technology to replace silver and other metals traditionally used in solar cell manufacturing.