Taiwanese researchers unveil 31.5%-efficient perovskite-silicon tandem solar cell

The cell utilizes a heterojunction device as the bottom cell and a perovskite top cell integrating a hole transport layer made of nickel(II) oxide and methyl-substituted carbazole.

Chinese PV Industry Brief: JinkoSolar, TBEA report lower profits

Five major Chinese PV manufacturers issued profit warnings this week.

Carbon dioxide removal portfolios enable reaching ambitious climate targets

In a new monthly column for pv magazine, the LUT University describes how carbon dioxide removal may support reaching climate targets from a portfolio perspective.

Novel BIPV concept integrates louvers to enhance power production

Scientists have proposed a building-integrated PV system that integrates airflow to cool the panels and control room temperature. The system, which also acts as a shading device, can reportedly mitigate drops in power generation efficiency without additional energy consumption.

Reducing silver use in heterojunction solar cells via low-cost copper wires

A research team in Germany has proposed to use direct wire bonding to reduce silver consumption in heterojunction solar cells. The scientists used low-cost copper wires as electrodes with conductive paste applied in discrete pads to replace the traditional metallization and interconnection process.

Brazil approves six labs for solar module testing

Brazil’s national accreditation body, Inmetro, has authorized six labs across the country to test solar modules.

French consortium building linear DC solar park along Rhône River

A consortium is installing an experimental linear solar park in shade house configuration in Vaucluse, southern France, using high-voltage direct current architecture to reduce electricity losses.

The best tilt angle to improve PV module performance in world’s worst soiling accumulation zone

Scientists have measured the performance of PV modules under strong soiling conditions in Saudi Arabia and have identified the most suitable tilt angles for improving power generation. They have also found that a key role is played by rain intensity, dust, sandstorms, and cloud cover.

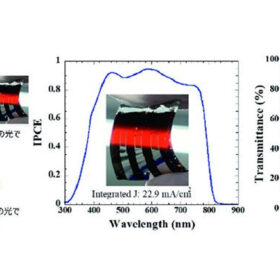

Enecoat claims 30.4% efficiency for four-terminal perovskite-silicon tandem solar cell

The Japanese manufacturer said its tandem cell utilizes a top perovskite solar cell with an efficiency of 22.4% and 81% infrared transmittance.

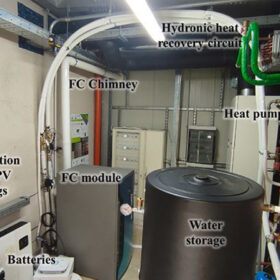

Italian scientists show technical feasibility of solid oxide fuel cells in PV-driven residential buildings

The researchers conducted a case study on a solid oxide fuel cell system deployed in a nearly zero-energy single-floor villa with a size of 80 m2 located in southern Italy. They found that, in particular conditions of photovoltaic production, the system is not only able to meet the home electric loads, but also to inject surplus energy into the network.