EVA the next supply chain pinch point for solar

With polysilicon production capacity having been rapidly rolled out after last year’s shortages, China analyst Frank Haugwitz has suggested global manufacturing capability for the ethylene vinyl acetate used on PV panels could struggle to keep pace with what is expected to be another record year of demand for solar.

Temperature-dependent model to calculate solar LCOE

Developed by researchers in Saudi Arabia, the novel approach considers both the temperature-dependent power yield and the solar module time to failure (TTF), among other factors. According to its creators, the model can be applied to all kinds of module and cell technologies.

France provides incentives to landscape-integrated BIPV

The French authorities have so far selected four BIPV products that are eligible for the incentive scheme.

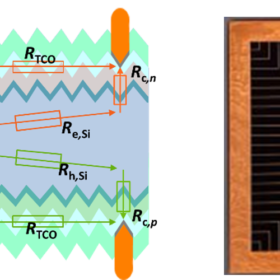

Bifacial heterojunction solar cell with 22.84% efficiency, reduced indium consumption

A Dutch-Chinese research team has developed a bifacial heterojunction PV cell with a 67% reduction in transparent conductive oxide (TCO) use. The TCOs used for the cell are based on indium(III) oxide (In2O3), which is considered a technology-critical element by many experts.

US consortium aiming for 50-year PV

The US Department of Energy’s durable materials consortium is a multi-laboratory unit that stress-tests solar modules for durability. It aims to extend the useful life of PV.

Solarwatt is the first solar module manufacturer enabling carbon compensation

The company’s German customers can buy, together with the modules, CO2 certificates so that the products are completely neutral. According to the manufacturer, the additional costs are about €11 per module.

Chinese PV Industry Brief: Xinte wants to add another 200,000 tons of polysilicon capacity

Xinte’s new manufacturing facility is planned to be located in Changji county, in the Xinjiang Uygur autonomous region. Moreover, Longi is planning to build another factory in Erdos City, Inner Mongolia.

Canadian Solar launches 420W rooftop solar module with 21.5% efficiency

The new product is part of the company’s HiKu6 series based on 182mm wafers. Its temperature coefficient is 0.34% and its electrical characteristics are claimed to be compatible with the most common photovoltaic inverters thanks to current values below 14A.

India’s PV module production capacity could hit 36GW by 2023

India’s solar cell and module production capacity is expected to rise in the years ahead.

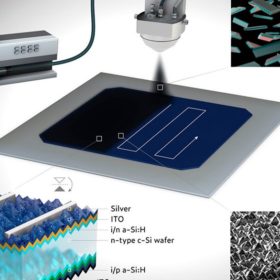

KAUST researchers achieve 20.1% efficiency in heterojunction solar cell based on 2D MXenes electrodes

The solar cell is based on the titanium carbide MXene and is claimed to have retained around 99% of its initial efficiency for more than 600 days of ambient air storage. The device was built using spray coating to directly deposit the titanium carbide flakes on the cell’s rear side.