Seraphim announces new module production in Vietnam

Chinese tier-1 manufacturer Seraphim announced plans for a new factory in Vietnam. The module assembly facility will have 750 MW total capacity and is expected to serve both local and international demand.

Solar facade for 3D-printed concrete house

Taiwan-based Heliartec has deployed a solar facade on a 3D-printed concrete house in Belgium. It said it installed the solar facade with the “circular construction” philosophy in mind.

Cooling PV panels with shallow geothermal energy

Iraqi researchers have demonstrated the technical and economical feasibility of using shallow geothermal energy to cool PV systems. They tested two different techniques – a closed-loop system and an open-cycle system – to reduce power losses from 30% to up to 4.1%.

The dash to glass

Hong Kong-listed solar company Irico New Energy is preparing to shunt its non solar glass business units into Chinese state-controlled parent Irico Group so it can treble its PV glass production capacity in 2024 with the help of a four-line, $108 million manufacturing facility.

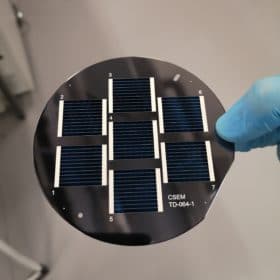

A 26.5% efficient perovskite-silicon tandem cell

Scientists in Switzerland achieved 26.5% efficiency on a perovskite-silicon tandem cell measuring 4cm² and relying on industry-standard screen-printed metallization, further demonstrating the technology’s potential for large-scale production and low-cost electricity generation.

US scientists apply Suns-VoC method to outdoor PV tests

Researchers in Arizona have used the Suns-VoC characterization method for indoor solar cell testing to monitor PV installations. The method can also be used with outdoor distributed-generation and large-scale solar arrays.

Biden, the EU and China to usher in ‘golden age’ for solar – Jinko

The company shipped a record 5.1 GW of modules in the July-to-September period and expects to hit up to 19 GW for the year, with ‘nearly 100%’ of its products likely to be based on monocrystalline technology in 2020.

Low-cost organic pigment coating for 21.1%-efficient perovskite solar cell

Scientists in the United States have conceived a new process to apply a low-cost organic pigment to perovskite solar cells. The new technique is claimed to increase the efficiency of the devices by around 1.2% and also to improve the cells’ stability.

PV module recycling could harm US solar industry

The PV industry can’t claim to be a clean energy source if it leaves a trail of hazardous waste.

The weekend read: Solar needs aluminum, but it has a carbon problem

Few doubt that aluminum frames will be a part of the solar module for some time to come. And with PV manufacturing continuing to scale, the carbon footprint of this versatile metal may prove a sustainability challenge.