Bifacial perovskite solar cells may become more eco friendly than crystalline ones

A US study has suggested the raised energy yield of bifacial perovskite devices effectively means they could have a lower environmental impact than conventional crystalline cells. The researchers considered single-junction cells with high and low bandgaps and similar, multi-junction devices with two and four-terminal structures.

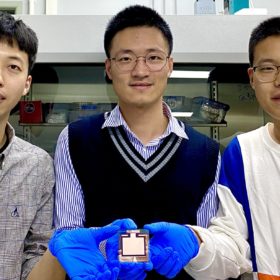

Additive allows all-perovskite tandems to hit 24.2% efficiency

Scientists led by China’s Nanjing University discovered that a chemical commonly used for bleaching in the textile industry can also serve as a performance-boosting additive to mixed lead/tin perovskite thin films. Using this additive, they were ultimately able to fabricate a two perovskite tandem cell measuring 1.05cm² that achieved 24.2% efficiency.

Gallium arsenide phosphide tandem solar cell with 25.0% efficiency

The demonstrated device, according to the academics, is built with interfaces between the active cell layers that improve the top cell carrier collection. The cell was built with texturing and a hydrogenated amorphous silicon (a-Si:H) passivation of a silicon back surface.

Renewsys announces giga-scale expansion of solar encapsulant and backsheet manufacturing in India

The solar manufacturer will expand its annual encapsulant manufacturing capacity by 1.35 GW and backsheet production by 1 GW.

Copper metallization process reaches pilot production in Germany

Scientists led by staff from Germany’s Fraunhofer ISE have demonstrated a new laser printing process in pilot production, which could replace silver paste and screen printing in solar cell manufacturing. The system is said to offer much more flexibility in the layout of contact fingers on the cell surface and a wider choice of metallization materials.

Improving outdoor I-V curve measurements with PV module irradiance sensors

Japanese scientists have replaced common pyranometers with PV module irradiance sensors to measure the I-V curves of crystalline silicon PV modules. The sensors provide highly precise outdoor measurements, the researchers said.

Concentrating photovoltaic-thermal system with 91% efficiency

A global research team has developed a parabolic trough linear concentrating photovoltaic-thermal system to produce heat and electricity, for both residential and large-scale applications. The PV unit relies on Azure Space’s multi-junction solar cells, based on indium gallium phosphide (InGaP), gallium arsenide (GaAs) and germanium (Ge).

Australian startup to replace silver with copper in solar cell manufacturing

Startup SunDrive has secured US$2.2 million in funding from the Australian Renewable Energy Agency to help scale its low-cost, high-efficiency solar cell manufacturing process.

Futurasun doubles production capacity to 1 GW

The module manufacturer has opened its second 500 MW factory in China.

Singulus bags Japanese order for heterojuction cell equipment

The German PV equipment provider will deliver ‘Silex II’ machines to an unnamed client.