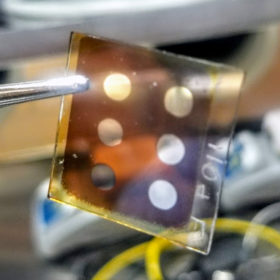

A flexible perovskite solar cell with 11.8% efficiency

U.S. researchers have created an inorganic mixed halide perovskite solar cell which they claim shows no thermal degradation even at 200 degrees Celsius for three days. The device can be used in tandem junction cells and is designed for use in real-life environments with high solar irradiation.

Chinese PV Industry Brief: Financials, a new GW-scale factory, and big hydrogen

Longi and Sungrow both announced solid financial results last week. Module maker China Solar delayed the resumption of trading on the Hong Kong stock exchange, and polysilicon producer GCL-Poly unveiled plans to raise up to US$16.8 million by issuing shares. Coal miner Baofeng Energy, meanwhile, announced the construction of what it claims will be the world’s largest PV-powered hydrogen plant, and Seraphim and Lu’An Solar revealed that they will open a 5 GW PV panel factory in China’s Jiangsu province.

Bangladeshi solar module companies seek Covid-19 stimulus package

Industry representatives call for a $59 million, five-year package of grants, loans and tax incentives from the government after Dhaka extended a coronavirus-driven industrial shutdown into the middle of the month.

Meyer Burger mulls gigawatt-scale German solar fab

Chief executive Gunter Erfurt told a German radio station a solar factory in North Rhine-Westphalia could supply high-efficiency panels for a 10 GW floating solar project on the vast Hambach open-cast coal mine.

Trina secures 105 MW order for its 500 W modules

The Chinese manufacturer will provide Indian developer SunSource Energy with its Vertex panels. Shipments will be made in the fourth quarter.

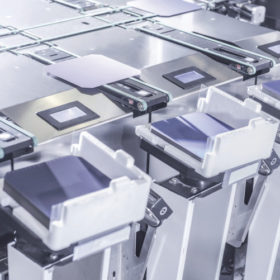

The weekend read: New technologies mean new approaches

Measuring the performance of a solar cell is a tricky affair, and even more so for new technologies such as perovskites and tandem cells. In the laboratory, these are measured over a period of several minutes to ensure accurate characterization. But as technology continues its journey toward commercial production, ensuring an accurate power rating without slowing down the manufacturing process presents a new challenge both for suppliers of flash testing equipment and those working on bringing perovskite solar cells and tandem devices featuring them to market.

Chinese manufacturers join forces to build 5 GW module factory

Chinese solar manufacturers Seraphim and Lu’An Solar will invest around $565 million in the new factory.

LCOE from large scale PV fell 4% to $50 per megawatt-hour in six months

Analysts at Bloomberg New Energy Finance say the lowest-cost projects financed in Australia, China, Chile and the UAE in the last six months hit a levelized cost of energy of just $23-29/MWh and the best solar and wind projects will produce electricity for less than $20/MWh by 2030.

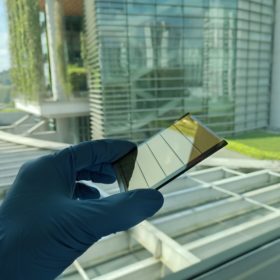

Mini perovskite module with 18.13% efficiency

Scientists from Singapore have developed semi-transparent perovskite solar cells that can be easily integrated into a range of urban contexts, including building facades, gates and windows. The 21cm2 mini panels are made of perovskite solar cells based on methylammonium lead iodine (MAPbI3), with an efficiency of 20.28% for 0.16 cm2.

Covid-19 weekly briefing: Merchant solar developers could seek shelter in return to subsidies and PPAs are being revisited, but at least the Irish are coping with lockdown measures

The unfolding effects of the Covid-19 crisis, and fears of a possible second wave, have split analysts trying to guess how the unsubsidized renewables market will emerge as slumping demand continued to distort power markets. pv magazine rounds up the week’s coronavirus developments.