Australian government stimulates PV in the face of Covid-19 threat

The federal government’s ‘economic response to the coronavirus’ legislation encompasses the installation of commercial and industrial solar.

Panasonic suspends work at Tesla’s Nevada fab as carmaker’s California and New York gigafactories pause

Tesla’s Nevada operation is still open for business, though. The EV and battery maker has assured the market its cash position is strong enough to weather an “extended period of uncertainty”.

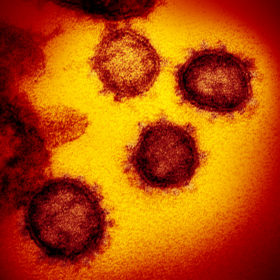

Ripple effects of Covid-19

Manufacturing operations in China are beginning to return to normal, with Taiwan-based research firm PV InfoLink reporting 80% capacity utilization across the supply chain in March. But the broader impact that Covid-19 will have on global demand for PV remains to be seen, and will depend on the extent to which the outbreak can be contained, says PV InfoLink chief analyst Corrine Lin.

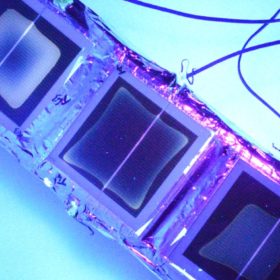

A second life for disused modules and EV batteries

A study led by Bern University of Applied Sciences is moving into the demonstration phase, with projects in Germany, Switzerland, and Belgium. With partners from all over Europe, the Swiss researchers are developing models for how solar modules and batteries from electric cars can still be used in a sustainable way after their lifecycle has ended.

Raising a PV system’s yield by 20% with mirror reflectors

A group of Scientists in India has demonstrated a 20% increase in a PV system’s energy yield through the use of mirror reflectors in the summer season. Though the technology is still far from being economically viable, the research shows that higher power yields can be reached without significantly affecting the module temperature.

Forget toilet paper, Australians are panic-buying PV

Byron Bay-based solar retailer Smart Energy says it is seeing an unprecedented surge in sales and enquiries for solar and home energy storage as consumers look to shore themselves up in uncertain times.

‘First shipment of 500 W modules’ announced

Chinese manufacturer Risen Energy will supply Malaysia’s Tokai Engineering with 20 MW of its new panels, unveiled in December. Risen claims its products can help reduce balance-of-system project costs by 9.6% and the levelized cost of energy by 6%.

Identifying early-stage discoloration in EVA encapsulants

A new, non-destructive method has been proposed by researchers in India who say identifying early-stage discoloration in EVA encapsulants can help detect degradation in solar panels before power output is affected. The scientists used an ultraviolet accelerated aging test during 34 days on three encapsulant samples.

Study of 100,000 arrays finds proactive O&M preferable

The US National Renewable Energy Laboratory examined five-year data to observe the most common system failure points and how to prevent them. Researchers considered residential, commercial and utility scale plants and found interesting results. While failures cannot be avoided completely, a key takeaway was that close monitoring and timely repair can effectively mitigate the financial effects of failures.

Analyst expects recovery for PV and storage supply chains

U.S.-owned analyst Wood Mackenzie expects solar demand to decline but predicts the market will recover, with the prospects for the energy transition remaining intact.