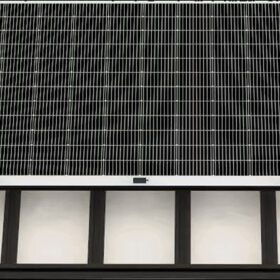

Sunman unveils 520 W glass-free solar panel with 19.3% efficiency

The new panel has a white backsheet and a temperature coefficient of -0.34/C. It weighs 4.1 kg per m2 and, according to the manufacturer, supports all types of installation methods, including roof adhesive and removal mechanical mounting.

Vehicle-integrated photovoltaics for electric ground transport

Canadian custom module manufacturer Capsolar developed a vehicle integrated PV system (VIPV) for an electric material towing application, reportedly enabling 30% to 40% range increase per battery charge.

Bulgaria launches renewables-plus-storage tenders

Bulgarian businesses can apply for funding under two new tenders that aim to facilitate 1,425 MW of renewable energy generation capacity coupled with 350 MW of energy storage. Funding support is only offered for the storage component.

European consortium targets end-of-life PV panel silicon recycling

A European consortium of 11 commercial and non-profit organizations is developing several technologies to make use of end-of-life PV panels by either re-deploying them or by recovering and reprocessing the silicon.

New modular design for offshore floating photovoltaic platforms

A team of scientists from China and the United States studied ways to optimize floating photovoltaics for offshore use. It found that the robustness of the systems was influenced by the size and number of platforms, as well as the types of connections between platforms.

Tests show rooftop fires propagate slowly with vertical PV systems

New tests conducted by the Slovenian National Building and Civil Engineering Institute have shown that vertical PV installations offer improved fire safety compared to conventional diagonal or flat solar arrays. The experiment showed, in particular, how rapidly a fire can propagate under inclined panels.

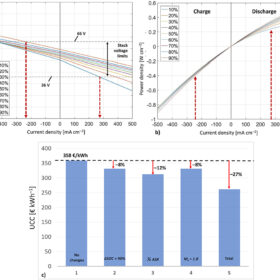

Evaluating the profitability of vanadium flow batteries

Researchers in Italy have estimated the profitability of future vanadium redox flow batteries based on real device and market parameters and found that market evolutions are heading to much more competitive systems, with capital costs down to €260/kWh at a storage duration of 10 hours.

247Solar close to commercializing modular concentrating solar plant

The 247Solar Plants are modular and most of the components are mass produced and can be assembled on site.

Quantifying effect of cooling, cleaning in PV systems operating under desert conditions

Scientists in Oman have analyzed the effect of soiling, cleaning, and water injection on the performance of PV panels in Oman. They have found the use of water for cooling may increase power yield by up to 23.9%.

Thyssenkrupp, Fraunhofer IKTS to set up 1 GW of electrolyzer production by 2030

Thyssenkrupp nucera and Fraunhofer IKTS want to develop and mass produce electrolyzers based on solid oxide electrolyzer cell (SOEC) technology. They are now setting up a pilot plant in Germany that is scheduled to start operations in about a year.