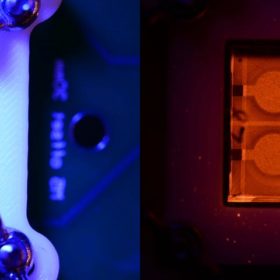

Six-junction III–V solar cell with 47.1% efficiency

A U.S. research group has developed a new solar cell, based on six active photoactive layers, to capture light from a specific part of the solar spectrum. The scientists claim that they could potentially reach a 50% efficiency rate with the new cell.

Manz to partially resume operations after Easter

The PV production equipment manufacturer said its employees will return to work at to two locations in Germany as planned after the Easter break, despite concerns about the Covid-19 pandemic.

Debt financing the main obstacle to PV during Covid-19 crisis

Industry body SolarPower Europe hosted a webinar to consider how the global public health crisis will affect solar. While workers and materials are still available, industry experts are concerned about the state of the financial sector. Banks could become more conservative and raise the cost of capital for renewables projects.

Software for virtual power plants powered by residential solar-plus-storage

With its sonnenVPP, German battery company Sonnen wants to improve the efficiency of virtual power plants which it says can offer primary balancing energy from houses with solar and storage and can operate up to 90% more cost-effectively.

Bringing green hydrogen to market

German companies Uniper and Siemens will cooperate on joint projects to advance the use of green hydrogen and sector coupling. Conventional, gas-fired hydrogen production plants will be gradually transformed as part of the initiative.

Shine! You’re on photoluminescence camera!

Researchers in Australia and China used intensity-modulated photoluminescence to map the series resistance of perovskite solar cells with a technique which could further understanding of the causes of instability issues in such devices.

A big grid solution to harness small solar arrays

Scientists at the U.S. National Renewable Energy Laboratory are developing a communication system to coordinate and control the volumes of solar power injected into grids by small scale solar arrays.

Australian researchers enhance clean hydrogen electrolysis

Griffith University scientists have unlocked a catalytic process to enhance the breakdown of water into hydrogen and oxygen and bring Australia a step nearer clean, efficient hydrogen fuel.

All-organic, sustainable proton battery from Sweden

A group of scientists at Sweden’s Uppsala University have developed a proton battery based on abundant organic materials. They say the battery can be charged “in a matter of seconds” while operating at low temperatures, and can be cycled more than 500 times without significant capacity loss.

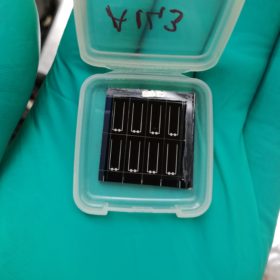

New process for kesterite solar cells with 10% efficiency

German scientists have developed a new process for the formation of a phase pure kesterite Cu2ZnSnSe4 (CZTSe), which they claim can improve the material homogeneity and suppress the well-known issue of tin losses. The new technique is based on stacked elemental and alloyed precursors with a Zn/Cu-Sn/Zn precursor structure.